Also covered, is Firing order and what is Bank1 or Bank 2.

You can be here for a vast number of reasons, (old cars can be a pain)

- Cam timing?

- Spark timing? removed distributor?

- The damper pulley rubber center , stripped out and now the marks are all lies on the rim, (use a TDC tool, is the only way, not replacing the damper puller {crank shaft front pulley)

- If the valve cover is off, you can time or check any

engine, by just looking at the valve action. ( after timing the cam

first) huh? (so take off the cover on the timing belt and check the cam

timing with out using the silly crank pulley marks ! USE THIS MARK.

- If the cam , crank and pulley marks are all good and the

valve cover is off, there will be no need to discover, TDC, it's

patently obvious and is covered in the FSM every little step, or on my

pages. Timing belt or SPARK.

The below checks, are for lost TDC , or the marks are wrong. The CAM cog wheel has 2 false marks, do not use them , nor the false keys (E and I) never use "I" marks to time the engine.

The below checks are needed for any distributor pull. (or be 180 degree;'s out of time, toss a coin) ALL 12 ways work !

G16A or B engines: (12 ways, did I miss one?, no )

There are only a few ways to check TDC. (the FSM shows compression test for finding TDC to install a new Dizzy) VC means valve cover.

- Compression guage (FSM mentions that way) #1 is

firing if the Gauge shows pressure rise , at #1 spark hole. (stop and crank pulley mark 0, at the end of the rise) All shops on earth, have this dirt cheap tool, why not use it.?

- Looking at the cam heels ?, (VC removed) or the cylinder with all valve loose ( 6 thou , .006") is the firing cylinder. If on heels, that cylinder is firing. (heels are on back side of cam lobes) The heel is that side , that the rockers or valve are not moving !

- If by wild chance, (been there) some dolt set the lash negative, say #1 valves are never loose? Test 1 will fail. So stop and fix that now, or you will burn the valves to a crisp.

- Lips Blowing { into spark hole 1 then 4, the one that can't be blown into is firing at pulley 0 mark. (by

far the best and easiest way) IMO ! I use a simple rubber hose in

my tool box. If lash or cam timing is wrong, this check fails.

- Putting a wad of foam ,or plastic in the spark #1 hole and rotating the Crank CW (clockwise) until it the wad pops out. Note how the Rad is removed., 8v takes more skill here.

- Putting your finger over the spark plug missing hole and feeling the compression, Dang hard to reach the 17mm crank bolt, if the Radiator is in place and the shroud is in place, in fact I must turn the crank laying on my back. Tell me how you can feel the spark hole and lay on back at the same time? (Spider man?) But if Radiator is out, it is very easy to do.

- People that trust the distributor rotor location?, Is ok if engine runs the rotor tip does point to #1 spark wire, at true TDC #1 firing, if not? Time the CAM first , then time the distributor LAST !

- If the valve cam cover is removed ,you can see the crank

cog mark's

and you

can see the 16v "E" mark DOWN is #1 firing, as is 8v cam spoke titty

down(early) and 60A spoke down, TDC firing. (this covers 10 years of

marks !)

- Using a TDC finder

tool (2nd most accurate) This will show all errors in the

front pulley, if its rubber guts are damaged.

- Using a dial indicator on the top of the piston with extensions, (dead

nuts accurate way, no better way on earth) "racing motors tests" (checked CW then CCW and the average, is true TDC)

- Some even use a vacuum gauge to find TDC at spark hole #1. (but is tricky to use) Youtube has videos of this method, I'll not show how. I never need it, after all the FSM way #1 works.

- Sure using a plastic drinking straw or real long tie warp

you can get pretty close TDC readings. (not precision like #10 and

11) It only finds TDC firing or exhausting. (only looking at the

#1 cam lobes proves this out)

Other facts related:

The crank turns 2 times for 1 CAM turn.

The crank TDC 0 mark are for both #1 and #4 firing. ( see both pistons are UP?)

The engine fires every 180º degree's of Crank shaft rotation (CW looking at the crank snout)

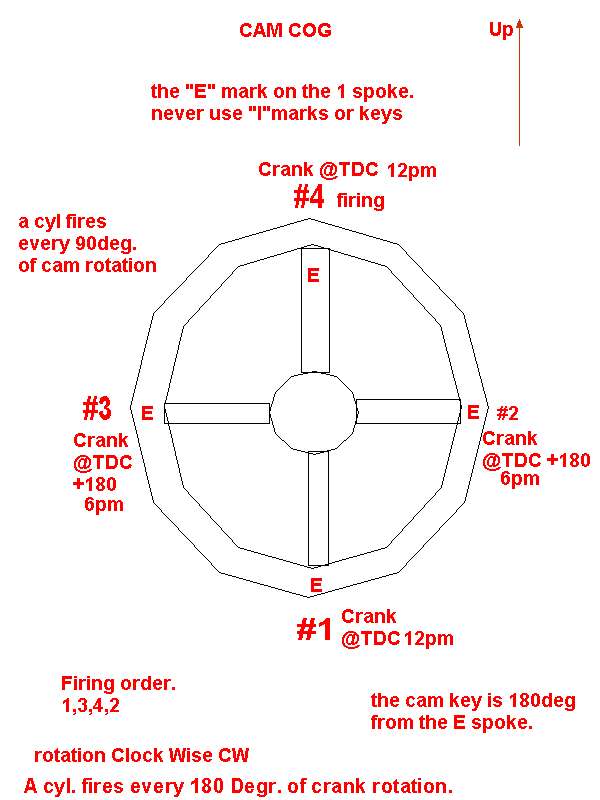

The cam fires every 90º degree's of cam rotation. (see graphic below)

The CAM "E" when at 12 PM signifies #4 firing ! The "I" marks are all false, on the 16v SOHC , both the outer "I" marks and the key "I" marks are all FALSE , use "E" ( the "I" marks are for the 3 cylinder engine))

#1 cylinder is front F1,2,3,4R (Front to rear) The V6 , the most forward cylinder is #1 , left front, USA drivers side, (LHD) cars. In UK that be passenger side, (RHD) but left always works, in any country.

This is dictated by the CAM shaft. (and distributor) Both the cam and crank turn CW facing rear of car.

The cam must be timed first then the Distributor, and if the lash is wrong? then this is done after timing the cam first. (cam, lash, spark, in that order)

The engine (Mr. "Otto" cycle) does CW , intake , compression, Fires, power stroke, then Exhuast stroke and repeats, the cam turns 1/2 the speed of the crank, to do that magic.

The intake valve is open so as intake air & fuel (no compression now), it closes and compression happens, and fires near max pressure, and then the exhaust valve opens (see that?, (no more compression now) and no more compression on the exhaust stroke piston going up.

The Technician knows these facts and with that knowledge he/she can watch the cam and know instantly which cylinder is firing (by watching the rotor tip or cam lobes, and the crankshaft TDC mark you can tell true #1 firing TDC)

If the dizzy is removed or scrambled (set wrong and now rotor is fibbing) then only the cam and crank marks work for finding true TDC (or do the 12 below ways)

If the crank pulley rubber is stripped only #10 &11 below works, or buy a new pulley. (I had this failure 2 times)

Keep in mind the base crank cog marks never lie (key no wrecked)

The 16v dizzy turns CCW the 8v dizzy turns CW.

Here is my Cam map. The wheel of Firing I call it. ( "E"= Titty = 60A in a my 10 year range) yes, Suzuki loves to change marks like phases of the moon....

Imagine the "E" mark (or titty mark on early 8v) moving to each of the 4 positions in turn below. FYI: One more titty motor a 91. ("60A: titty at 12 pm is #4 firing)

My drawing is crude, but very clear what is happening when? no? It turns clockwise. (CW facing motor))

Imagine the "E" mark moves, as you turn the crank and see who is firing.. below. (older motors have titty mark and no "E")

4,2,1,3 is the same as 1,3,4,2 see?

The Timing belt is always done at #4 firing and , ignition timed at #1 firing (the engineer of the engine, did that, those are how the marks were made and the bias on the belt is easier on #4, roll the cam by hand and feel that bias)

Graphic #1

E = Titty or 60A spoke (E is 16v and the other ways are 8v)

The easy way to time the dizzy: To #1 firing point. (Rad in place, and all covers on the stock OEM motor are inplace, can't see cam or valve rockers.)

TDC #1 for ignition. (TDC #1 can be found 3 ways, the lips blow tests, or the wad of plastic blow out test, or use a compression guage (FSM WAY is COMPRESSION gauge way..) (all 10 ways here)

Gauge way1:

Attached a compression guage,to #1 spark plug hole (yes, remove this sparkplug) turn the crank CW until the gauge peaks and fine tune the crank pulley for V notch TDC 0º alignment.

The Lips blow test.

- I turn the crank pulley, to the crank TDC mark , there is only one 0º degree mark on the Tbelt cover and outer rim of the pulley, (clean pulley mark it with liquid paper)

-

I removed all spark plugs for easy turning, or just #1 & #4

- I then place a rubber hose against the spark hole #1 and blow with my lips.

- I can can blow in to #4 but can not blow in to #1 , that means #1 is firing. (if both blow, then the cam is timed wrong or lash is all wrong. (fails compresion test too)

- if #4 is firing then rotate , the crank 360º degree's CW. to TDC again.,

- #1 is now firing, and you can NOT blow into #1 spark hole..

- If both blow, you have valve lash set wrong, or the valves are bad.

- A good motor that passes a compression test.

- All sparks removed for easy crank turns, by hand.

- Put a wad of paper or plastic bag in the #1 spark hole.

- When the wad blows out of the engine, bingo TDC #1 is firing (it is about to fire, the wad blows before TDC)

- advance the Crank pulley to the TDC mark. You are BINGO for setting the Dizzy timing.

The cam timing can be checked with our new Sneak-a-peak procedure. Will not prove key strips see the end of this page for the ACID test.

The below rules are correct, most over the counter books , show this wrong. (as does 1996 GM/Geo books)

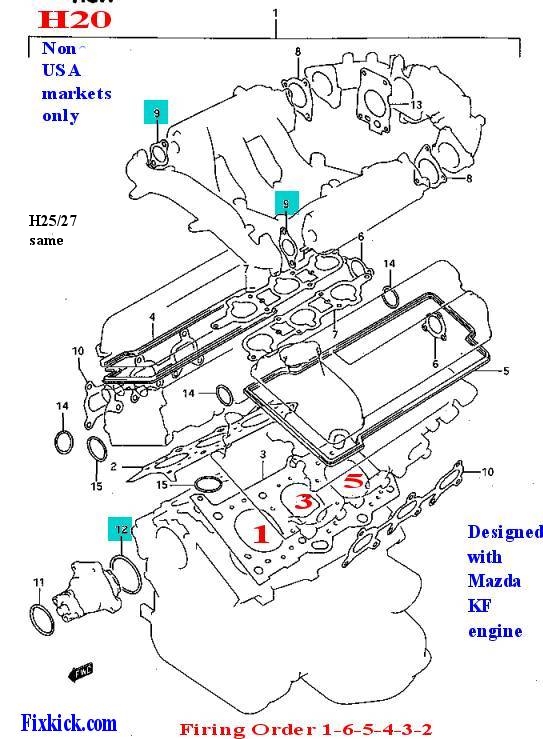

Gaphic #2 Each distributor can in fact be time 4 ways but the below is the factory way, and alows for the harness wires to fit right.

If you find yours timed different, below, then just document what you have, and leave it alone. (running car)

FINDING TRUE TDC 0 degree's"

If the crank key is stripped or damper pulley bond, lost, use this tool to find it.

This one is better: (longer for 16v) This is the better tool fits both engines.

Related:

See my CRANK LOCKER PAGE ( ALL WAYS)

Timing has a perfect order of your action, here is that order: A sure path to success.

- The Timing belt is 1st (do the acid test to be sure its correct.) The cam is timed at #4 cylinder firing. How to time the CAM is here.

- Valve lash set perfect next.

- The Compression test now passes. (150 -8v and 170-16v PSI minimum) done near Wide OPEN Throttle.!

- You now have a good engine. A MILESTONE !

- You set the cam, and crank to #1 firing. (see blow tests) or the other 13 ways.

- You look at the Dizzy rotor shaft ,with the dizzy

rotor removed, if a real OEM type rotor?, it only fits one why, if not

sure, all the next steps are worthless. (don't china made , clone rotors SUCK !)

- 8v rotor metal tip aligns like this long side.

- The 16v rotor metal tip aligns to the long flat side

- Ok ,the Dizzy has some hope of delivering spark, to a real

spark plug. (sigh) (use oem spark plugs set to .028" and never at

.045")

- Insert the Dizzy (if removed) So the rotor points to 11am 8v or 1pm 16v. I lay down the the spark wires per graphic #2 (simple huh?)

- I then crank the motor and use my timing light to set timing to the under hood sticker spec, say 5 degrees before top dead center TDC, 5º degrees is 2-1/2 marks to the left, on the Tbelt cover scale.

- if motor starts here, then set the timing again with the timing freeze jumper planted.

- No starts?

- I use test fuel, with the fuel pump defected to test a good

motor and good ignition, then when test fuel runs perfectly , I

then work the EFI fueling side. That's how I do it , in the correct order.

To defeat the fuel pump, remove the left rear tail light lens, (super easy) then seperate the large connector with the large pink wire. Pinkwire is pump. Now you can use test fuel checks and not flood the motor.

On pre 96 cars the fuel pump relay is under the ECU and the socket is green and the key wires are again PINK.

Do not pull fuses to run a motor on test fuel as that, kills spark.

ASE and SAE.org conventions: Day 1 training, in any autoshop class. (and Suzuki unique)

Right means right side of car, from person sitting in the drivers seat. facing forward.

So RHD (right and drive, (UK?)) means the drivers seat is on the right side facing forward.

Drivers side of car means ZERO , nothing to me. UNLESS I'm standing there. (in the UK the driver sits on the right.) so, avoid this jargon.(for sure on international forums.

SAY LEFT or RIGHT facing forward, this works every time.

RULES:

The most forward cylinder is #1 be that a I-4 or V6, look carefully on any V6 or V8 or larger, engine and one cylinder is more forward.

On any front wheel drive car, the #1 cylinder is closest to the crank shaft pulley. (opposite side of the transmission side)

Then engine can have 1 cylinder bank or 2, (oxygen sensors , are identified by , by Bank number)

The word UPstream means closer to the Engine head exhaust valves or in forward of the CAT, (catatlyst device) Sensor 1 or S1 means UPSTEAM. S2 means down stream.

Bank 1 is always on the #1 cylinder side.

Some cars have this large I-6 engine (means inline 6) and has a splite exhaust manifold and the rear is bank 2. (California cars , this is very common) JEEPS.

All I4 engines are firing order 1,3,4,2 unless its a boxer engine (pancake engine)

The V6 is. below. all Suzuki V6 of any displacement. 165432. (this works only on Suzuki V6, other cars engines may have other firing orders. (My Jeep is 1,2,3,4,5,6 order, on the 3.8L V6)

The firing order is no concern to you, unless, your car has and old tech. DISTRIBUTOR (HV wires off or fiddling these parts) (replace wires 1 by 1 and WIN. {HV means high voltage spark plug wires.}

DIS means , DistributorLess Ignition , system. (of 2 types, COP or Wasted spark, COP means coil over plugs, wasted spark, are unified coil packs ,DIS.

The Firing order (DIS) is fixed by the PCM in all COP engines, and the COP harness is a tight fit and can not be crosswired wrong.

This is not true in any COIL pack DIS engine, seen in Europe, in this case the PCM sets firiing order but the wire routing (HV) must be correct at the coil pack, most good packs are marked, 1,2,3,4, etc. so mark them now if , not mark is a WIN solution.

Cars with wasted spark coil packs, 2 in one or 3 in one or 4 in one pack the high voltage lugs must not be mixed up. The are usually marked, if not ?YOU DO IT.

On all engines, the firing order is important to persons working with cams, cam chains or belts (cam timing) and for spark timing and adjusting , cam 2 (left) rear CMP sensor.

Connect any timing light to left front cylinder,#1 (below)

On all engines, you can find TDC firing using a compression gauge at #1, at peak pressure , at the TDC mark this is firing. (you can blow air via a clean hose with lips to the #1 spark hole and if you can't blow, its is #1 firing now.

The crank shaft turns 2 times, to complete firing of all cylinders, and the cam(s) turn(s) 1/2 the rate of the crankshaft.

Sad but true?

I See people time a DOHC interference engine (vast are) and not respecting it enough to , log in to alldata.com pay $15 then proceed to destroy a $3000 engine , now that is dumb. Zero Repect for the engine, or cash. totally.

A smart tech, ASSUMES all DOHC engines will do that. (my Miata 1.8L not)

Check all timing 3 times, then hand roll the engine sparks out ,feeling for resistance !!!

Do a cylinder leak down test first, by hand and never use the starter, yet, make sure it free running, and the leak down test passes all tests. (or stop and THINK just one more time)

rev 6 ++++ 3-27-2013 ---- 10-1-2015, added the conventions sections.