THE ISSUES:

You motor races (idle is way too fast) (before reading this page , go back and read the rules first)

The purpose of this page is to find Air leaks into the induction plenum, Or to correct idle regulation issues.

YOU ARE HERE BECAUSE the idle speed bleed screw fails to lower RPM below 850RPM. (or special rule on 89/90) or you have serious idle regulation issues.

The below is for the 8 valve motor which love to race with any illegal air leaks. ( by design, all Speed density EFI systems do this)

1989 to 1995. (N.American Sidekick's and Tracker)

16v motors go lean and bog with illegal air leaks. But does act like the below COLD. cold only the 16v will race if illegal air enters the induction. see end for elaborations on that.

Illegal means air not controlled by you ( gas pedal) or not controlled by ECU. (leaks)

This list makes finding the problem a rote process, using as little testing, as possible , and few tools.

If the below seems complex?, and it is, then go to a good shop.( this is a mechanics bread and butter $)

See my IDLE out of control pages.

See my 1993 MPI example.

WHO DOES WHAT, WHEN?

Given that your right foot is off the gas ( air) pedal (throttle) :

A Cold motor , all air comes from the IAC and ISC and the Idle air bleed. ( the PCV source is non important, unless its hose is cracked)

On the hot motor the only source is ISC and that Idle Air bleed screw. Hot = 180F or greater

( on the 89/90 years, there is no idle air bleed screw, you must fiddle the throttle stop screw, never do that in years later)

There is one more device for a cold start and only on 8v motors and that is the dash pot. This device holds the throttle open for 2 to 30 seconds, at cold start.

After 3-30 seconds, all 8v motors retract the Dashpot and idle will drop to the air rates (idle) controlled by the IAC and ISC valves.

All other sources of AIR, are illegal. (Illegal can cause lean bog or too fast idle , or both)

On an 8v motors, all air leaks raise idle speed too high with full powe, no lean bogs. This also applies to 16v when the motor is cold and rich, as it will be.

On all 16v motors (hot) all illegal air leaks cause lean bogging. ( many kinds, of bogs, hesitations or flat spots in power delivery) There are many synonyms for bog.

In General :

This page you are reading, assumes the ( motor is good ?, motor is tuned up ? , and that the ignition timing (and cam time) are at factory specifications.

The Check engine lamp is out running and the EGR main valve closes (flex it with your fingers the diaphragm or remove it and clean it and test it)

The EGR gaskets on the ISC or IAC can NOT be missing or cracked.

Motors with Ignition timing set way advanced ( set wrong by a crazy mechanic or slipped timing belt) , advancing the timing will cause the RPM to rise and the ISC to fail regulation.

All vacuum devices locator maps, are here.

Detailed information on 8v motors, for air leaks and some 16v comments.

All sensors and actuators tests are here.

The below, is a logical and procedurally easy and progessivly harder test ordering.

I will assume the car is 89/90 as it is the worst case so skip the lines, in Red ,if car is newer? Items in italics are not found on 16v cars.

If you skip a test or use non valid test methods, the conclusions will be bad.

The motor is running (idling and motor is fully hot)

Tools:

A vacuum hand pump is mandatory $26, to test for a leak on the peripheral devices. (exceptions don't make the rule)

An IR gun (no contact, no danger) to measure accurate coolant temperatures. Infra-Red thermal gun $9 .

A digital multimeter a DMM. (DVM,etc) Harbor freight has one for $3 , and cheap IR gun too.

A FSM for your car year. (a real ! Factory Service Manual $20 on Ebay)

TESTING !

We first hope the problem is outside the engine., then at the end, we attack the TB (short for Throttle Body) and then the MOTOR induction, as a whole.

On all 89/90s if you suspect the IDLE UP, Diode block is bad or, then unplug it ! Then see if idle speed drops. If it does , then the block, is bad or its inputs are wrong.

Items in italics are not found on 16v cars.

Keep in mide if the ISC is online working all air leaks will be hidden by its normal actions (job2).

To find leaks by using the RPM drop method, I must defeat the ISC (open the bleed screw to get it to stay running)

or use the duty cycle meter. If you have say Duty at 65% , and you pinch a hose and it drop lower, you just found a leak (do not pinch the ISC hose as this is a normal leak path)

In each case below I show a RPM drop but if using this meter, the Duty will drop for all vacuum leaks.

One way to defeat the ISC is pinch its main air hose, and then turn the bleed screw ccw max. bleed leaking to keep engine running.

A second way is to open the idle switch, this shuts off idle controls ( take screwing the TPS and that cause lost TPS calibration, and no fun there)

CHAPTER 1: (hot idle fails) The pinch tests, expect NO IDLE drops during the test.

(the below tests will fail if the ISC is alive and working) If the idle speed is way above 800 or below then the ISC is dead and the below tests all work.

(assumes ISC is defeated in some way , the ISC+ECU normally will hide vacuum leaks and hold RPM at 800 even with leaks added)

- The Motor must be hot, you

checked it with a IR GUN or DMM

thermistor sensor and is at least 180°F (the IR-GUN will read

170°deg

F

at the water outlet thermostat housing) Replace the

thermostat, if reading below 170F.

- Look at the DashPot device (DP) on the Throttle Body (TB) make sure it retracts after cold startup 3-30 seconds and stays that way, hot running all the time. !

- IF the DP does not retract after 30 seconds cold

start, stop and repair that. Just looking at the dash pot is all

that is needed here.

- Make sure the Gas pedal throttle cable is not binding and

hold the throttle open , same with 3speed kick down cable and cruise

cable. all must be loose fitted. "The FSM covers ALL THAT"

- (look down the TB bore with a flash light, see 100%

closed butterfly with Dashpot manually retracted with you hand or with

vacuum at its nipple. if OPEN, YOU FOUND A PROBLEM.

- Now the pinch test: Pinch each hose, on the induction manifold one at a time, skipping almost none. see list below for results. Pinch each hose and as close to the vacuum source, as possible (induction side).

Motor is idling.

- Pinch the Evap, hose at the manifold , not the

canister. expect no idle drop. see

vacuum maps here.

- EGR main hose closest to EGR main, no idle

drop.

- The MAP (8v) hose must be tested manually, remove it and make sure the filter is clean (blow through it?) and do a leak down test on the hose from the TB side to the MAP (connected at MAP) disconnected at TB (motor off)

- Make

sure the MAP vacuum hose sucks air when you start motor ( doing so,

will cause limphome.) but this tube must have full vucuum all the time

running !) Remove or block aftermarket Cruise control

transgressions here.

- Do not pinch the PCV , the PCV is new

because

you did a tuneup, and now you only need to inspect the hoses for

cracks. NO cracks allowed here, at all. Make sure PCV valve rattles.

- Newer cars 91+ have a EVAP VSV , pinch the

Vacuum line

between the Intake nipple and the EVAP VSV, no RPM drop allowed. On 89/90 the EVAP has no VSV and vents to the air

cleaner side.

- Pinch or block off the brake vacuum booster hose. (see booster , follow its hose back to the intake, find a way to block it closest to the intake manifold ( no RPM drop allowed, pinched or plugged off)

- On newer cars (91+) there is no

EGR thermal switch ,nor any

Distributor vacuum advance but these hoses must not leak

air , if present , Pinch the single vacuum source hose to both these

devices.

- The Dashpot, Running Test 1, first pinch the

DP

hose

and see the

dash pot extend and raise RPM greatly, about 2500 rpm hot . We

already know the DP retracts after starting.

- Dashpot test 2 , now stop motor, and remove

the DP 2 with 2 screws, then start car and pinch the DP hose as

close to intake side of VSV

as possible and expect no RPM drop. VSV /hose test.

- We are done with all the hoses at this point and we do not have any RPM drops above. We now proceed to the more difficult ( my examples here, are from easy to hard.....)

- The TB (8v) or FuelRail has a Fuel Pressure Regulator and a small vacuum hose. do not pinch it. (remove it and make sure the hose is not cracked, and do a leak down test on the FPreg diaphram )

- On the 8v remove the dashpot hose and do a leak down test on the dash pot vacuum nipple. same as the FP regulator. use 8 inches HG as test value and no leak down allowed after 1min.

- All

Diaphrams devices, on car must be leak down tested. (DashPot, EGR

main, 89/90 Vac advance , all ) for 1 minute , 8 "HG rule.. HG =

Mercury column in Inches (look at gage). Make sure tool don't

leak first !

- If the RPM is still way too high? First look for a blocked open TB , butter-fly plate or one with coked up sludge below it , blocking it open. A flash light shined down inside works great, motor killed, Dashpot retracted by hand !

- The 89/90 has a throttle stop screw , low and at the rear side, unscrew it and see if you can reach 800-850 rpm. HOT. 800 is Ideal.

- On 91+ cars , adjust the air bleed screw on the front of the air horn of the TB. ( it has a rubber cap hidding it , so look carefully ) Always use the air bleed to set idle , 1991 and newer, Never adjust the throttle stop !

- 16v cars the idle bleed is located on

the top rear of the TB ( Throttle body.)

- Next 89/90 we remove the ISC and

block the

ports with a solid gasket or with clay or ? . (89/90) then start

car

and idle should be way below 800 rpm. )(500 -600 is typical RPM ,

it must drop greatly !)

- On the 91+ cars

, pinch the top ISC hose

( air) and see that RPM drops below

800 RPM (on a normal car, if RPM hot is 1500 and you pinch the

ISC and it drops o 1200 , then the ISC is working to some degree.

- If if RPM dropped then good ! but not below 800 , you do have a serious leak , one so bad, the ISC can not correct idle or regulate idle at all. Don't blame ISC yet.

- I unplug {electric conn.} the ISC , this causes it to close and idle must drop ,if not it is stuck or dead /bad. The RPM usually will drop by about 200, leave it unplugged as we go below.

- if the ISC can not drop RPM both ways, then

it is leaking .

- IF the ISC test, does not cause a drop in RPM drop below 800, then there is a leak somewhere. The pinching of the ISC air pipe is one test and unplugging the ISC electrically is another, the last test must drop RPM by 200.

- The 16v motors the ISC hose is large and must not leak air, if it does?, the cold motor will race and the hot motor will be lean at low throttle settings (bogs and off idle TIP-IN hesitations).

- We are done with ISC

, next is the IAC. ( 8v

and 16v are very different looking, but work the same way !)

HOT !

- We now

remove

(harder) the 3 screw 8V TB lower

base front cover plate, Pack it

with clay ( I use "Electricians Duct Seal" ,Easy to remove

later.) Use

a solid base gasket on 16v IAC to block it,or pack the TB horn port to

it.

- IF the bocked

IAC blocked RPM drops HOT , the

IAC is bad , test it in a

pan

of hot water (not an easy test) but the 8v can be examined

hot, with cover removed ! , It must be closed over 150F ! Coolant temp.

- Make sure Someone didn't fiddled the Idle stop screw on the 91'+ throttle body? , set the idle bleed screw bottoms out (clockwise) this must drop RPM below 800 or there are leaks (hot)

- The TPS was installed wrong and the Throttle is now blocked open via the internal TPS engagement wrong., see TPS install rules and preload, here.

- If motor still races? continues below: (we have gasket failures. The above 16 test , I do additively , all things that drop rpm are repaired or left blocked as I continue my goal of below 800 rpm idle. Once there the ISC will wake up.

- I use propane gas ( flaming not) played about the gaskets

of the TB and Intake manifold , ETC !, listening for RPM changes?

No RPM

changes allowed running. Hot is

best method !

- You can spray water , this can seal a leaking gasket, droppng RPM, and is safe. I use propane, but other brave souls use CARB cleaner, which is not safe. And NEVER GASOLINE PLEASE !

- A

PRO uses his smoke machine.

Snap ON tools:

- If line 1 above fails (RPM changes) then we must

remove the offending item, what ever it might be. Last remove the

induction manifold and inspect ALL gaskets associated with

the TB.

- At this point , replace all TB gaskets and all Intake manifold gaskets and end it. It leaks , it's bad, replacement is the only solution.

- Induction off, do take a straight steel mechanics ruler 18" or more, across the intake mount to head, and check both the surfaces for flatness and no more of 0.001" inch /per foot feeler gauge surface warp age.

- If warpage is found , ask your machinist for help. (an easy

fix for him)

- The safest to most dangerous tests are , Smoke machine, EYE ball inspection, Water spray, Propane , and the last is liquid fuels (CARB cleaner which is a very dangerous flammable liquid , if you and car survive !)

- The Injector Cushions can crack and leak on a 16v MPI engine. As can all TB gaskets (up to 3 on 89/90) , ISC gasket, EGR gasket, and Intake manifold gasket. Felpro sells great gasket kits ,QUALITY, is the word.

- Do not attempt to do Chapter 3 if you have problems

with

chapter 1 or 2 or a failure of the rules on the previous page.

16v comments:

The 16v MPI car has all the same parts except the MAP is gone and is replaced by a MAF and 3 more injectors that can leak air.

Many Same rules on 16v: see exceptions.

Hot engine, any air added that fools the MAF results in lean (bog)

any air that the MAF can see, results in faster idle.

- The engine races if motor is cold and illegal air

enters the plenum. (too much fuel + air = racing)

- ISC stuck open will make it race at any time.

- Throttle blocked open in any way the engine will race,

anytime hot or cold.

- IAC stuck open at any time will results in racing.

Testing the IAC on a 16v need removal, or removal and blocking it with

a gasket after replacement and further testing.

- Any air that leaks around the MAF (between MAF and intake valves) will make a hot motor bog, or cold motor race.

- A coked up MAF hot wire results in bogging

motor. (under reporting MAF, allows excess air and too little

fuel to match it)

- The idle bleed will raise idle at any time just like an 8v.

This bleed is above on top of the TB to the rear.

- On a hot motor , all gasket leaks result in bogging

- Pinching air lines (vacuum lines) work exactly the same way on 16v motors.

- The IAC can be tested in a hot pan of water just like the

8v. 150F and above, it must be fully closed. (some books say 158F)

- The 16v can have leaking injector cushions. causing cold fast idle and hot bogging.

- The 16v can not tolerate any air leaks on that top of the motor AIR pipe. unlike the 8v who cares less ( ignoring dirt being inducted, as bad)

- Hitting the MAF gently , if this causes idle changing , the MAF may be bad. (a GM FSM check)

- Any tube of rubber on top of motor for air , that is

cracked

will cause , lean bogging hot ,and fast idle cold. PCV, ISC

tubes. etc.

I'm sure I missed something, but this covers most air leaks. ( I did not cover cracked housings.... )

EXAMPLES are best, here is mine: Finding vacuum leaks is not easy. It takes hard work but I offer some good clue below.

IDLE is screaming hot. at 2000 RPM.

The engine reaches or bests, 180F coolant temperatures, the cars heater works at full hot setting, I use a real tool to measure this heat. (not guessing)

I make sure the coolant water flows through the IAC hoses. (by checking that carefully) if not the IAC under the throttle will fail and idle will scream.

My car has 3 throttle cables. (A/T , Cruise and gas right foot pedal) all three as set loose, as the FSM tells you , you must DO.!

I look in my TB air horn and make sure the butterfly valve is 100% closed , not like this.

OMG someone turned the never touch screw. On the front of the Tbody. (so I correct that now)

then....

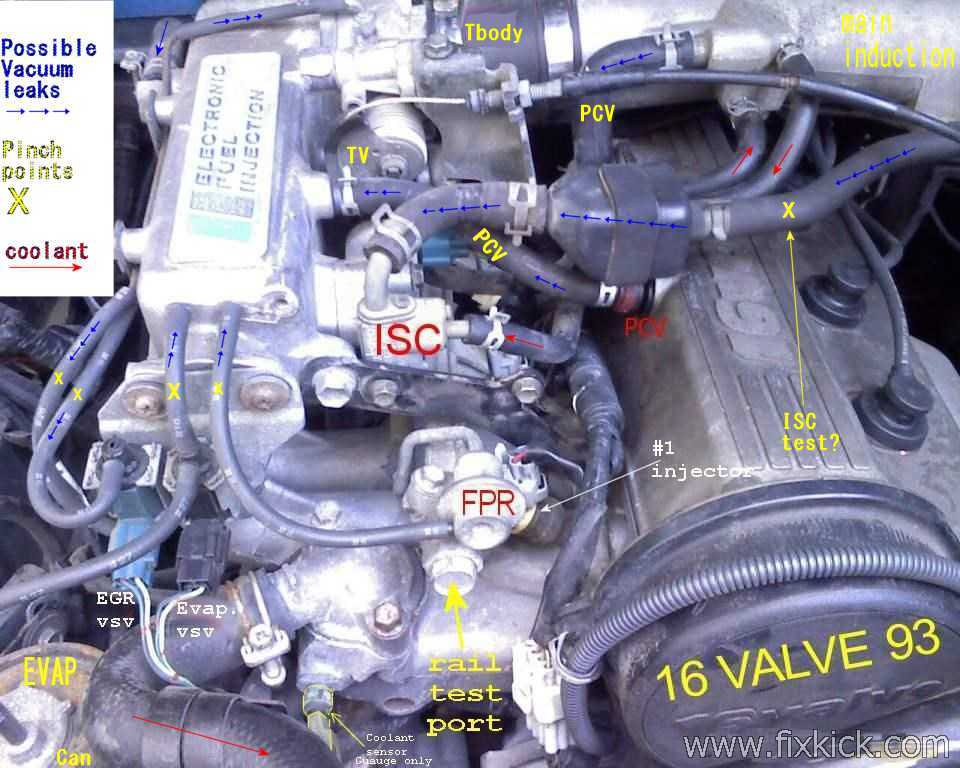

The yellow X's are my pinch test points, using Pliers not fingers.

The 4 lower left X hoses when pinched must not CAUSE any RPM drop. (except)

I pinch those 4 and only the Fuel Pump REg. FPR hose, may cause a small change. this is ok.

Best practice on Freg hose FPR, is inspect it, (no cracks) and do a leak down test on the FPREG vac. nipple

The brake booster is hard to pinch , so I disconnect it on the right side of plenum and plug that hole with a cork. (it can't leak now, OMG it idles now, so it's a bad booster, after hoses check out.)

I then Pinch ISC test ? X hose hard. If the RPM does not fall much or only a tad. (bad) It must fall to below 400 RPM . I now know the air vacuum leak is HUGE . (this test is the best of them all)

The TB has an air bleed screw that adjusts idle speed duty cycle. I screw it in gently CW RPM drops a bit but engine is still screaming at 1800 rpm.

I then test the IAC under (using clay) the TBody and it's stuck open. (I replace it and my leak is gone)

Or that passes my tests, find air leaks in the booster hose, or injector cushions, or in the PCV hoses.

Lets say my pinch at X ISC test ? did drop RPM way low say 500 RPM, that means the ISC is dead. (stuck open) clean it. and test it. 100%

There are other leak points. ALL plenum gaskets can leak. the plenum is this vacuum chamber under words, Electronic fuel injection.

The intake manifold can leak at the head too. Or Tbody bask gasket. any vacuum hose.

The ISC Test ? hose, test, is my KEY stone test, this tells me all I need to know, (causes)

On a normal car, system it idles near 800 (even in DRIVE) and if I pinch X (isc test?) the engine stalls or nearly (hot) this is because there is no air now. not much.

Below is the 1993 G16B Engine. (HOT PINCH) the blue Arrows are possible hose leak points. the red arrows are hot water.

The ISC can correct about 400 RPM worth of air leaks. After that the ISC has lost control of the system. (in crude general terms) ISC means Idles speed controls, The IAC is 100% closed at all times over 150F coolant temps.

The ECU use the ISC to keep hot idle from 750 to 850 RPM and does so full time at idle. (if the idle switch is open, then ISC will dead)

See SAE JARGON names here.