EGR failure 1996 to 1998 . (OBD2 systems) See slide show of carbon clogging.

History perspectives:

All 1996'+ Sidekicks/Trackers have the SST tube #9 (SST= Stainless steel) 8 year life rated...

Some 1996 X90's cars have tube 9 , but the first years have the early intake Quad EGR port manifold.

OBD2 , started in 1996 and switched to EGR monoport intakes. and a new Check valve.#15

With new OBD2 DTC codes. ( P0400 is EGR failing, now)

A new EGR MDP MAP sensor (baro type) part ID #29

The live test must be done moving, or fooled into thinking that, VSS shows faster than 0 miles per hour.

The OBD2 conducts 2 tests for P0400s now, making it harder to pass. (cruise and coast)

Some Canada cars do not glow the CEL lamp for 400s; You must scan it to see it, (cute huh?)

Keep in mind the EGR can be 100 % working (in a smog context) but only the test parts are bad, the check valve or MDP.

OBD2 is a U.S.A invention, so this page is just a USA topic.

Fails Code DTC P0400, via the OBD diagnostic monitors (x2) or your car loves to stall at traffic lights.

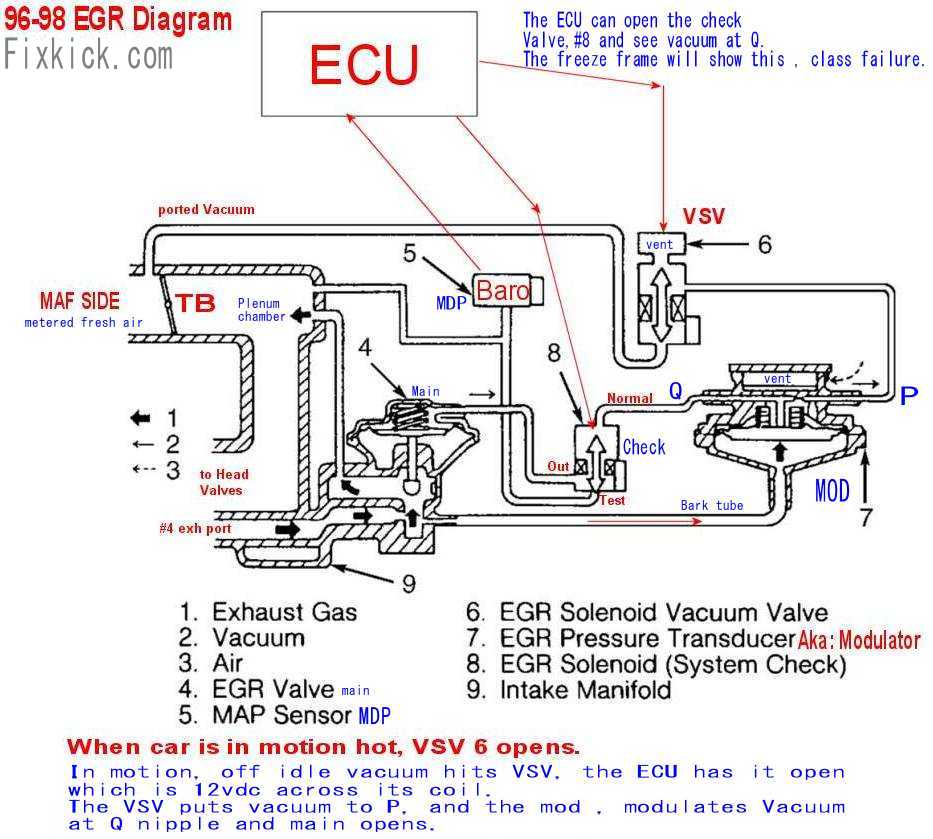

These newer cars have this basic system, shown below.

If your engine is running rich and you keep melting the cat or packing it with carbon, the EGR is not your priority , it is just a victim.

Get the engine running right. A 60 PSI fuel pressure {BAD}, can cause an overheated CAT and failure, and a fully carbon packed, EGR system..

There are 3 major tests to do , in this order : The stall test, the bark test , then the Live test.

Keep in mind the 4 paths to failure here:

- Exhaust path. Exhaust port #4 to EGR main and to #9 tube

then to hole "A" This is the goal and proper flow to stop NOX , cruising.

- The vacuum side can fail. (VSV solenoids and hoses)

Open hood of car, look up, see vacuum map?, is it connected right? look

!

- ECU Electric side, the ECU never fails, but the TPS switch

failure makes the EGR fail. (idle switch bad or calibrated

wrong) The VSS sensor must work or EGR will fail.(speed sensor)

- The PUTT PUTT side. (bark tube) this is hose #35 if the EGR main nipple

clogs , EGR dies. if the CAT is missing, the MOD valve #4, can not do its job

- A bad EGR VSV2 valve, the diagnostic check valve

stuck open, can cause failed EGR codes.

What to do first?: (The Stall test)

This is the test logic:

- Do the Stall test. if that fails, do the bark test if pass do the live

test.

- Clean the EGR main,

now if the stall test failed.

- The bark test, if passes, the #4 exhaust path through the

head is good and the #4 header hole is not packed full. GOOD!

- If the bark fails the exh. path is blocked EGR to #4

- The bark test now passes and the EGR is cleaned, and Hole #1 is clean, on to the Live test.

- Do the live test, on a 1996+ it one tricky test.

(1996+ means 96 and newer to 1998)

- If the live test passes, the EGR map (MDP) is bad or just needs cleaning, or you

have a huge vacuum leak in the plenum. "does the scan tool show LTFT at +30% not -5?, bingo?"

- If the live test fails, do the VSV vacuum tests.

- As always 89-89 (not 99'+) the CAT must not be

clogged or missing. If it is , the EGR mod valve.#4 goes dead. (missing

cat = EGR dead, clogged, causes excess EGR flows)

- Do the stall test, if that fails?, clean the system. (the stall test is not 100% effective, but very good, Make sure tube 9 is not necked down to 8mm, OBD will fail)

- Clean hole 1. then prepeat the stall test, in fact, do each of these below and stop when the stall test passes.

- I now use, an 11mm drill bit to clean hole 1 and

the head tunnel, (both on mine were 11 to hit bare aluminum)

- You must treat some X90s with the quad port, in the intake manifold , like found on early 92-95 kicks. (just the ports, then come back to this page above)

- Clean pipe #9 below, called the sidewinder. It loves to clog mid section or

neck down to 8mm and fail. (well hidden)

- Clean EGR main #1 below , it must move 1/2" it must not be

clogged, or leaking, or stuck open and the spring inside must be good.

(it MUST SNAP shut !)

- Clean the Throttle body hidden hole "A"----> seen below. (a very tight "S" turn ) see photo here. of it ! aka: HOLE #2 from H3LL.

- Clean

the EGR Head tunnel.

Pull Exh. manifold or intake,

easier? and ream the head tunnel with a 11 mm drill bit or a 11mm

gun brush.

- Clean the Exhaust manifold. #4 EGR feed tube drilling.

(theExh. manifold must be pulled. (I left this hard step for

last)

- Part 34 clogged? (MAP filter? check valve? both?) Usually part 4 (MOD) and 29 (MAP) last forever. Part #1 MAIN lasts say 100,000 miles.

- The live test is the best test. I shows you , the whole system working as one.

- The VSV tests are here.

- See the end for the packup photos. Horrors.

HOLE 1 must looks like this, clean . (an 11mm hole it is , and clean back to the 90deg drop down (likes to clog at the turn too) and out to tube 9

Once the stall test passes then proceed to the live test.

Drawing# 1 below shows the whole vacuum and EGR system. (my comments are in red) Dwg#1

The Location of the EGR main is below left, and I have pulled to plenum chamber, for easy viewing. Click photo to zoom. Photo 1:

In 1998 the Plenum chamber can not be removed. (97 4dr below)

Note : NO EGR THERMO PROBE ! gone forever Yah ! No EGR coolant switch , double cheers. Starting 1996

One ECU for all 96's and each year a different ECU.

This EGR system , is simular to the 92-95 systems , has the exhaust originate from the #4 exhaust port and then pass through the rear head tunnel.

The EGR exhaust gasses pass through the head, to the rear of the intake manifold.

Here is my 92-98 head tunnel.

This gas then reaches the EGR MAIN valve ID. #1 above.

This Valve can open and allow the exh gasses to pass in to the intake plenum via #9 SST tube and the 11mm oriface behind the TB valve.

T.B. = Throttle body.

There are many failure modes for EGR, but the most common is clogging of the passages. (air leaks in the plenum can cause bad reading from part #29 EGR map, above)

If the car will not idle correctly (low idle or stalling, at traffic signals) or the Check engine lamp flashes, code 400, then we need to take the following actions.

A bad TPS and or ISC can cause stalling too:

- clean the EGR MAIN part #1. Remove it and clean it with

Carb cleaner spray. Make sure return spring drops the valve closed each

time.

- then once clean, do a stall test.

- if the stall test passes then the do the live test.

If the stall test passes, then do the live test.

If the live test fails, you have bad EGR valves.

If the live test passes. then look for restrictions.

The Stall test. ( the brave can use their finger tips to press the diaphragm, but vacuum is best) (vacuum tests 3 things, fingers only 1)

First off , the stall test is SUBJECTIVE and as some say not DEFINITIVE. sure, all true, but if it passes my test, and then you pass smog, I saved you $1000 in labor. huh?

The stall test does work every time finding a dead EGR function, no lie..

The only question that is hard, is does the Flow at the EGR ports, meet factory spec. (there are 6 places (sections) for restrictions to happen.

I feel the Diaphram plate, seen below, says Push here.

I feel it and push it , engine off, to see if it moves 1/4" (6mm) and that it snaps back with a THUNK, telling me it is not sticking and is CLOSING fully. I repeat this 10 times. sticks?

If not sure, buy a new EGR and use that. (learn to feel a working one first)

Preconditions: (sure the engine runs perfect, if not , all this page is a waste) { a lean running engine can fail EGR tests. or huge vacuum leaks}

A Hot engine is best: 800 RPM is correct. ± 50 RPM , if idle RPM is wrong, the below tests are not valid, fix the bad idle speed first. (or fix bad AFR,etc )"air fuel ratio"

- I connect my hand vacuum tool to the small nipple and pump it to 8 inches,HG, (700 kPa) I hold there, not moving my hand, for 30seconds, it don't leak down, this is a good diaprham.

- I then start the engine, and pump it down 1 more time stalling the engine. (or on real strong engines, I get about 400 RPM and it shakes like a wet dog. This is a PASS test.

Shakes?, is gross misfiring on all cylinders. ( this is why stuck open EGR stalls you, at every stop light ,when it is bad)

Video below:

On this car , apply vacuum to the #1 main EGR valve nipple and pump it up to 8" inches HG of vacuum.

The video above, does not show the tool, in had, but he is pulling a 8 inch HG vacuum, on the EGR MAIN vacuum nipple, for sure.

Engine now fully HOT, apply vacuum to the small nipple and the engine must nearly stall or stalls. (the near stall RPM is important)

This symptom is a pass (stalling or nearly).

Later with a working EGR system , practice this stall test, to learn your stall RPM... practice makes perfect.

If the RPM changes none or way too little? (a 100 RPM drop is too little), then the EXHAUST path is blocked. (end to end, long path) the #1 cause, is EGR packed or hole #1 packed.

- One way to do this with no tools, is to steal the EVAP #38

(dwg#1) hose main vacuum nipple. This is hard plenum vacuum. Do not

touch the other non EGR vacuum nipples., only #38

- Use a spare test VAC. line, for $1 and pinch it with vise

grips, attach one end to the plenum nipple 38 and the other end

to EGR main, below. (its line pulled and plugged up)

- Start the hot engine,and release the pinch. the engine

stalls. 400 RPM or stalls.

- This working right, pretty much proves the problem is on the vacuum side or VSV electric side (or EGR MAP is just dirty, or mod valve issues?)

- The ends my stall test section.

BARK TEST:

I made this up, the bark test and name and saves tons of labor if it fails. (at least you know, what needs to be done ,when you have the time.)

It's real simple (stall test failed so....)

EGR main, (above) removed. (use penetrating oil on the screws, and jog them gently, do not exceed 10lbs force turning them. (10 foot/lbs) spec is 7.

The mount base has 2 large holes, the Vacuum suck hole and the Bark hole, this bark hole is the Cylinder #4 exhaust header tube, supply.

- Main EGR valve removed. (and was cleaned)

- I block the vacuum

hole in the intake EGR main port (near right fender), seen to

right in linked photo, the suck side blocked with a rubber cork. (or what ever can't get sucked in)

- I start the engine, and the left port above, barks load ! GOOD, I don't need to ream the head tunnel and #4 exh port (COOL !) It will be very forceful, or this needs attention.

That is it !, the bark is done , put back the MAIN EGR, use antiseize compound on the 6mm threads.

The Live test. (harder on 94+ cars) [ the moving axles rule , happened mid year 1994 and is true all years forward]

By live test , we mean, the EGR is REALLY working, and injecting the correct amounts of exhuast gas to the plenum. (in this case , car in motion)

Buy live I mean, The ECU opened the main VSV and the system works. ( it flows and you can see the EGR main diaphragm move , flex inward)

Do not waste time doing this before the Stall test.

See my new live test failed page here.

- Get motor good and hot, well over 170deg. F. 180F+ is a Normal

hot motor. Accessories OFF. A/C , radio, Defroster , FAN. Hot idle is 800 RPM.

- Chock the front wheels, a 4"x4" board works ok here.

- Jack up the left rear tire/wheel off the ground. Be on flat ground.

- Only 1 rear wheel must be raised , "in neutral" , running, HOT, and by hand spinning 1 rear tire. To do this test. Speedo needle, most move up a tad !.

- Rev up the motor and the EGR valve must move more and more as RPM rises. The Diaphram can be viewed with difficulty (a mirror?).

- If

this happens ,

the whole system is operational, and only the flow is in question. Keep

in mind you will never get full flows, with no load, in neutral.

- EGR MAIN #1 is stuck closed, clogged or the diaphragm is

cracked (do a leak

down test on the diaphragm) The stall test passed so.... this line is not the cause.

- The VSV VALVE #22

is bad never opens,. or the EGR CHECK VSV valve ID

#15 above is stuck open , causing a nice vacuum leak..

- The vacuum tubes are cracked or plugged up.

- The main Exhaust port #$ is plugged up.

- The Head tunnel at the rear bottom of the head it plugged

up,with carbon.

- The EGR ports in the intake manifold #1 or #4 are plugged with carbon. One at end of #9 tube and one more oriface behind the TB.

- Mod valve failure, or CAT missing , or core inside missing.

Follow this procedure to test the VSV valve 22.

Follow this procedure to test the CHECK VSV valve 15.

Last, is the Modulator test.

If the live tests pass, then do then next test.

EGR MAP (MDP) test:

The EGR MAP can fail if clogged, or the induction plenum has a huge are leak or the engine is running vastly lean.

The ECU reads this map (baro) sensor to see if the EGR dropped vacuum and thus proving the EGR did open. DTC Code 400 this sensor detecting wrong vacuum readings

Test 400 is two tests, test A and B, one checks the EGR using he check VSV and the other test is via the normal VSV1 driving way.(real way)

The SCAN tool can see the freeze fram page and see if test A or B failed. (one test is at CUT fuel mode and is the easy way to see which test it failed at)

Sadly if VSV2 #8 below, sticks closed, the EGR is 100% ok but throws 400s. (a false Positive)

P0400 H3LL

See all you need to know about test P0400 here.

A Typical EGR functional map

Here is the map sensor test for 96+

Below, is the typical USA 1996+ EGR systems. (1998+on some Canada (E28 market) cars.)

Note how the VSV2 (CHECK) part #8 below, if it sticks open, the EGR test will fail. and is not used during , normal driving, it's only used for one of many tests, P0400.

The VSV2 and #5 baro sensor (egr map"MDP") are new in 1996 and the NEW OBD2 ECU. This new baro sensors only job, is to sense the EGR main going open. (vac, drop test)

Make sure the vacuum lines are routed correctly (see drawing 1 above)and the plenum nipples all are unclogged and suck air when opened.

The EGR live test, proves the ECU can open valve 6 and that the #4 Diaprham moves. If not?, use vacuum tools on those line to diagnose the cause.

The VSV 6 below , with no power is open. (when not open the MOD line Q is vented to the top filter in the VSV 6.)

Keep in mind the ECU cuts he VSV 6 at idle and wide open throttle and for Not moving. (3 ways)

The ported vacuum cuts all EGR actions, at idle too.

One can overide 2 rules by one trick:

From TB to MOD 7, If you unplug the VSV 6 elect. connector, the VSV 6 opens, and you can do that, to see if gunning the throttle will move the MAIN #4.

Gunning the throttle puts vacuum on the ported vacuum hose below.

If the CAT is missing the bark tube below MOD 7 will be dead, or very weak. CAT back pressure is manditory to make this system work, at all.

The MOD valve , is the the final deciding factor on actual EGR Exhausts flows to the TB plenum.

Trick 2, while doing all above, is to blow with lips into the MOD2 bark hose, (use a longer clean fresh hose) and this will latch up the MOD and full EGR action will be seen at #4 main.

If all tests pass, then maybe the EGR baro is just dirty, remove it and make it clean. ( use "CRC" MAF cleaner on all delicate parts)

The above comment, about a tiny orifice, is not true on 96 and newer cars, this was corrected.

Below, Carbon choke point 2, this ones in the trash. END OF LIFE.

The below links and photos shows the common fail points for 96+

Look here and clean hole #1 with 11mm gun brush ! or 11mm drill bit !

or ram it with a #3 Phillips.

If this side pipe is missing, then your X90 car is a pre 1995.5 car. (mfg dates before Sept. 1995 have a quad port egr nozzle intake man.)

Yes they maee cars well before the model year 1996,.

(shipping delays dictate that,early build... std, industry methods)

The Sidewinder tube, Drawing 1 , ID #9 More cleaning points below. Note steel wire rope cable for cleaning out passages. (I spin it in a drill motor)

See slide show of carbon clogging.

jam this wire rope upward and inward 90 degrees to get to the rear of infamous HOLE #1 (ACE hardware, garage door opener wire!)

and the last point to clean , if you must is this point below, see tie wrap.

The software monitors:

1996+ OBD2

What really happens during the P0400 OBD2 monitor test and normal driving: 96+

The EGR monitor uses a different set of rules to be conducted using the following OBD2 rules sets: PAGE1 and PAGE2

It waits patiently for the operator to accidentally be driving the why the monitor desires, then it takes a snap shot and passes or fails the car.

If the tests fail (any) the ECU sets a FREEZE FRAME. This can be viewed using a quality OBD2 ,scan tool.

Now you know which tests fails.

Cruise test 1 or Deceleration test 2.

If you think you are cured the P0400 by cleaning or ?, then reset the DTC codes and drive above the speeds shown in page 1 and 2 above.

Cruise above test 1. 19MPH. Note MT has a tight RPM range.

Then Decelerated from above above 28 MPH. Note RPM limits below 4000 rpm.

Vacuum map: Make sure yours is routed properly.

Under hood sticker required on all USA cars.

Horrors:

SEE, See slide show of carbon clogging.

ver4 , 11/11/12