NOT for 1989 to 1995, 8v TBI engines, go back one page or hit home above, same with 1996 and newer.

Reasons for wanting to solve this are?:

SMOG man made you, Check Engine lamp DTC error code 51 or P0400. Most folks outside smog zones just skip this.

or the engine stalls at idle? (or near) coming to a stop sign?, want cooler running exhaust valves?, and 1/2 MPG better economy?

All that, is your call !

Keep in mind, there are 3 systems to fail, (4?) Exhuast path, vacuum path and electrical, or the sensor that is used to read out the test is bad (or clogged).

For EGR monitor tests (51/400) to pass , the ECU part number must match, the correct EGR valve and EGRT probe if present, and the engine harness. (mixing Fed and Cal parts is NO GO) DTC 51 and 53 fails?

Do the stall test first, if that fails, then clean the EGR exhaust side, that is clogged using this bark test.. No tools? try this.

See (newer) slide show of carbon clogging and cleaning paths.

Conditions for setting code 51 are here (my best guess, new !)

History is important here. (evolution of system ;only USA history) Generator 2a and 2b. (early and late years)

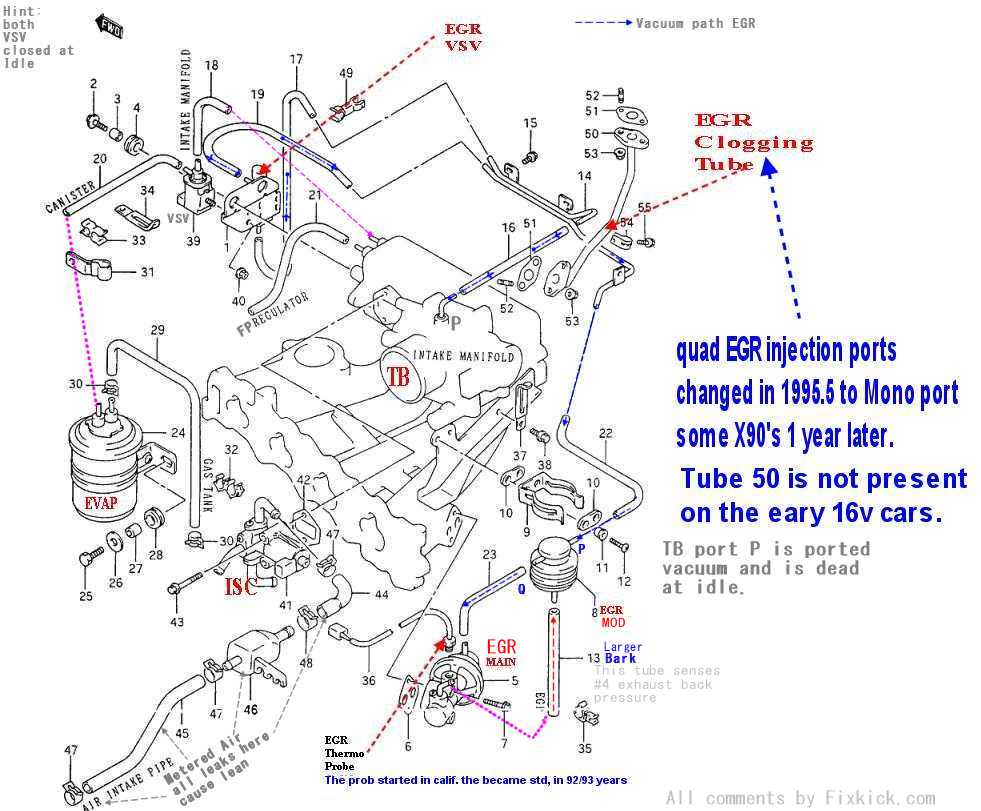

See early 16 Valve Drawing #1 below left.

Is the early quad port EGR. , the second drawing is the Mono Port EGR with part 50 seen in Drawing 2:

Drawing 2 , Pipe #50 started mid year year 1995 at chassis vin -S6400xxxx (suffix of 17digit vin) S= 1995 and is a mid year production change out. or 1 year early in California due to C.A.R.B laws there.

Suzuki stopped using the quad EGR port intake and switched to new mono port ,which I call a MonoPort Intake, just one hole for EGR injections.

I call 50 the sidewinder (like a snake, it will bite you if clogged up , but is easier to clean)

If you see tube 50 present ,then it is a mono-port intake manifold with matching Throttle body.

In both systems, hose #19 (22,23) will be dead, natrually, no vacuum at idle, at all times. is normal.

If you find vacuum there, then you have a failure, or control issues, with EGR VSV and the ported vacuum in the actually throtltle body. (vacuum at idle is cut 2 ways!)

If you have this drawing 1 quad port system?, those quad ports are a SOB to clean. (on a scale of 1 to 100 , they are 100 sucks rated)

Early G16B

Drawing 1 (super secret inside intake hidden quad port EGR gas injectors and PITA to clean, a personal horror this is.. " read, a lost weekend".)

Drawing 2: Below MONO PORT EGR SYSTEM Below G16B late,

Is vastly easier to service. The system gets a new intake manifold/plenum box and part 50

Part 50 arrived in 1995, and on non 4 door, more early. (keep in mind many engine swaps , can happen and you get a newer 1995+ intake system.

The First vin with part 50 is VIN suffix ~S4100182~ and S6400091~ (S means 1995 year)

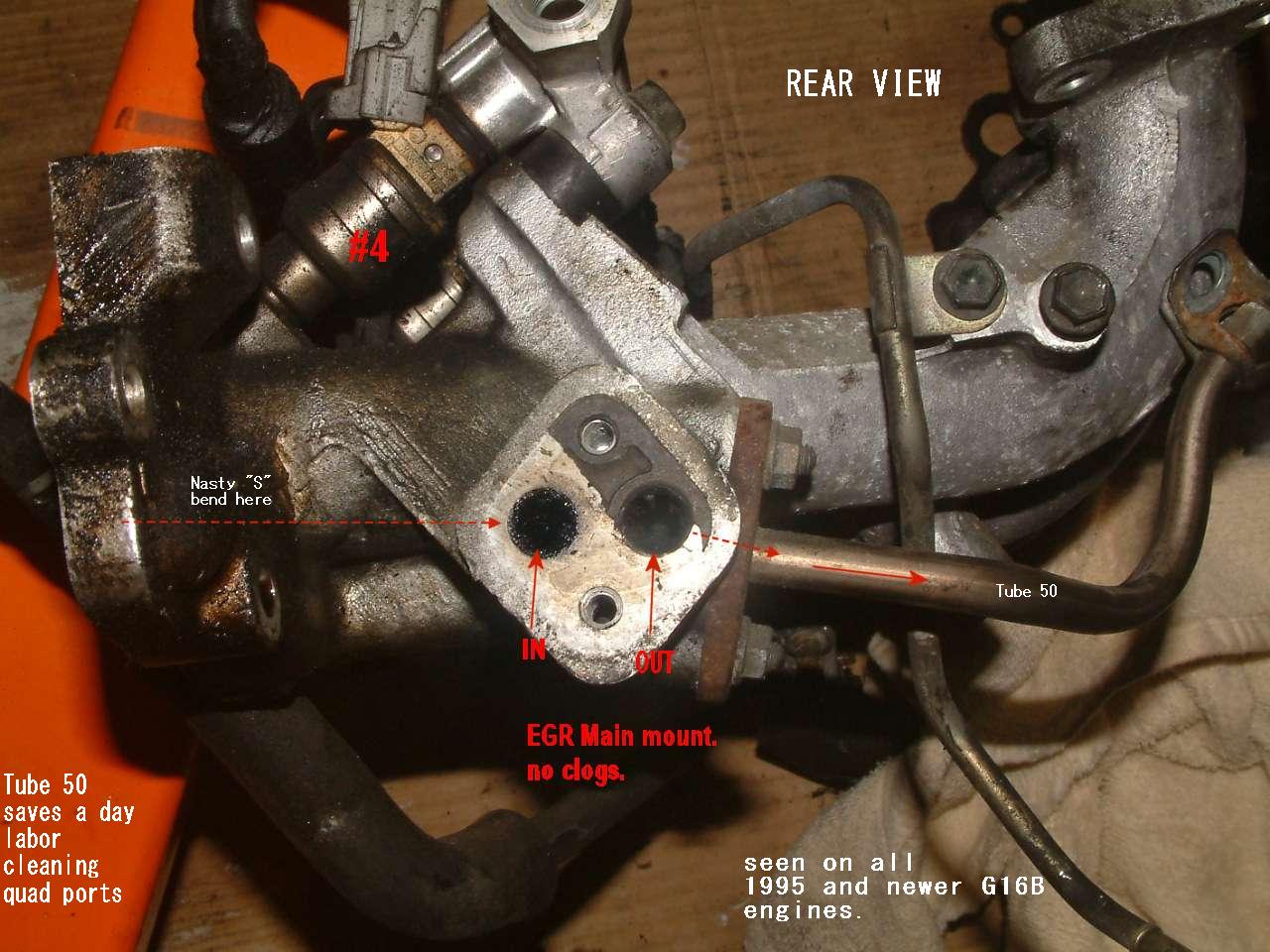

The actual tube 50 is here.: Tube 50 is seen to the right, here, (EGR main removed) and tube is SST, "stainless steel" As you can see carbon is an issue on engines that run poorly (rich as a pig) this is REAR OF INTAKE MAN.

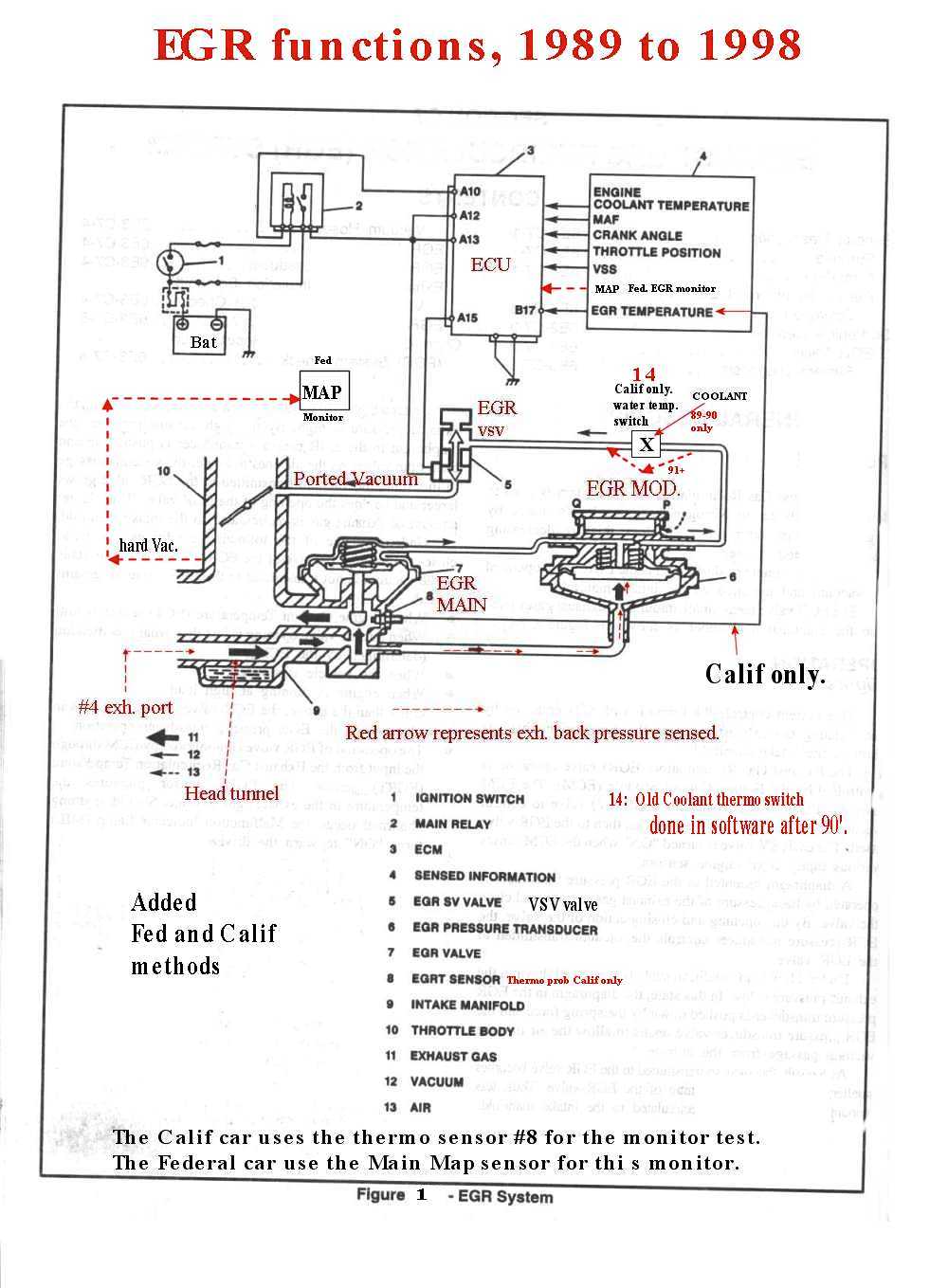

EGR System Variances by Market , USA, Calif , and Federal.

Part #36 Drawing2, is a 1992 Calif.smog part EGRT but was later adopted to FED cars in 1994. A THERMOPROBE !

Some FEDeral versions have no part 36 (93/94) , NO EGR THERMO PROBE. See year list at the end of this document.

Some FED cars and CAlif cars have different ECU's and software for the EGR monitors. (mixing ECU's years and CAL /FED is a problem)

The newer ECU's will puke DTC code 53s if the EGRT #36 is missing or unplugged.

THE Exhaust PATH:

This system , has the exhaust originate from the 4th exhaust port and then pass thru the rear head tunnel.

The EGR exhaust gasses pass thru the head to the rear of the intake manifold.

This gas then reaches the EGR main valve #5 above, via a crazy "S" turn in the INTAKE manifold.

This Valve can open (moving only after 94) and allow the exh. gasses to pass in to the intake plenum. (metered and modulated by #8)

The Tube 50 began mid year 95 and replacec the early 4 port very hard to clean induction seen here.

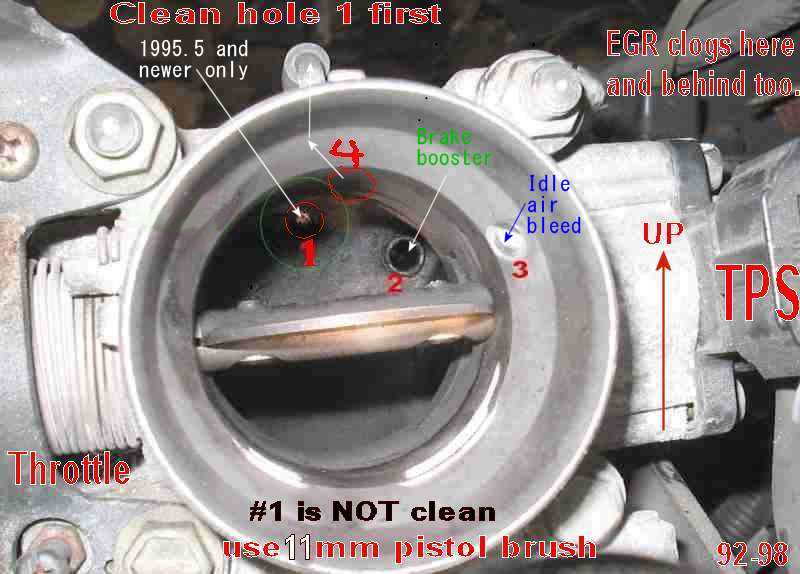

Tube 50 , feeds HOLE #1 the EGR monotube injector from mid 95 to 98. This hole loves to clog and I clean it first always even if the stall test passes, below.

The Location of the EGR main is below left, and I have pulled the plenum changer for easy viewing. Click photo to zoom.

Photo 1: SEE EGR main? and the 95.5 mono tube 50 , sidewinder. at 6 PM?

This view shows the hidden EGR main very well. bottom left center.

Ignore the mono tube at bottom, (rusty flange) it's only found on 1995.5 cars. or newer Kicks.

The top PLENUM is removed for photo convenience, below.

The 1998 plenum is not removable. Below is a real 1997 USA G16B sans PLENUM.

Photo 1: This photo shows just how hard to reach EGR main is.

The rusty flange, at the bottom here, is the tube # 50. Found on all newer engines. 94 to 98 years.

Overview: (only Fate , luck or running in FAILSAFE mode for years, determines what part is bad or dirty)

There are only 3 systems that can fail, (exhaust path, vacuum path, and electric path) (a 4th is the sensor but that is electric too.)

There are only 3 tests, do them in the correct order and win, do them before cleaning and save lots of time

Do the stall test , the bark test and the live test. (in that order)

If the car will not idle correctly (low idle or stalling {or near or below 800 RPM hot} every time you stop , then the main valve is sticking, clean it or replace it.)

If the Check engine lamp comes on running and with DLC diagnostics jumpered, the CEL flashes, code 51, then we need to take the following actions.

The engine will run ok with 51s (not stuck open main) and only causes hotter head intake valves and failed smog tests. 51s are not a crysis in 60% of non smog tested cities.

Diagnostic Test Flow: MACRO VIEW: ( my flow saves time/labor) Why spend all day cleaning parts, when the VSV valve is dead)

From easy to hard !

- EGR main is

jammed, on a cold motor the main valve diaphram is stuck, stuck

closed or open. Its bad. you found 1 problem , use index finger

to check it.

- Do the Stall test: (if pass?

do live if fail , then do bark)

- The bark test (if bark passes? and

stall passes? do live)

- Live test. passes,? (all above

passes,too)

- if all the above passes? and you have part #36 EGRT , then test EGRT , here.

- Keep in mind non EGRT cars can fail 51's for intake air leaks. (or lean running AFR)

- Component tests on, or off the car. VSV can be tested off car.(or on car with a vacuum gauge)

- if any thing fails, clean it and then test each part.

- if stall fails and bark passes attackh the intake, if

the car is mono port , clean hole #1 now.

- The quad part intake manifold must be remove to clean those pesky 4 quad ports.

- Cleaning the EGR, manifold passages, is near

the

last thing to try, but must be done you can not get stall to pass. (a

large RPM drop)

- Last is new parts. (not all EGR mains can be saved some stick only when hot, by cleaning but most can)

- Clean Hole 1, if you have it (95.5 and later). do not forget this spot either behind hole 1.

- Cean the EGR MAIN part #5 above (at rear of Intake

manifold, seen in photo above) 10mm bolts x2

- Remove MAIN, and clean it with

Carb cleaner spray. Make sure return spring drops the valve closed each

time, and is not stuck open with carbon chunks.

- Once clean? do a bark test. ,EGR is removed. plug the EGR port on the right side, start the engine and see if it barks load at red arrow a path here, then stall test should pass.

- If the above bark tests fails clean the head tunnel, located here.

- if the bark test bark test dont pass on the right side with a clean tunnel, (passenger side of head ) then clean the Exh manifold path #4 port tunnel.

- The Stall test must be good now or you have this 4 port induction. that must be cleaned , I dont envy you.

If you dont believe any of this ,then by all means clean it all. Be my guest. (I clean only what needs it , sorry I'm no carbon slave...)

If the stall test passes, 800 drops to 500 RPM or less , then the path can be restricted. but is usually restricted at hole 1 or the quad EGR injection point in the intake manifold.

I do ream out Hole 1 with drill and the use a gun brush to get it all clean.

My logic:

If the live test fails and stall test passes, then you have bad vacuum or electric VSV problems.

If the live test passes (and DTC51 remains) then look for restrictions, in the main exhaust path , weakj Mod valve , CAT converter blown out or clogged.

If the live test passes and DTC 51 remains and the car is a CAL car, check the thermoprobe, as per below. REGTS.

The Code 51 monitor used the EGRT to show the main is open and flowing exhuast and sees that via the fast temperature rise of the EGRT.

It can be fooled with a replaced (EGRT removed) simple 10,000 ohm resistor ,the ECU test is that dumb.

I call the cars lacking the EGRT thermoprobe, FED cars ( because it was INTRODUCED on 92 Calif cars)

The FED car uses other engine load method or MAF changes to detect EGR ACTION. (im not sure how?)

The CAL car uses the EGRT to detect the rise in exh temperature as the EGR main opens,. (this is easy to see with any ohm meter scale ,running)

The ECU and a special EGR , determine which method of EGR monitor tests are used.

ALL 95 cars are EGRT fitted.

The Stall test. (Details) Very simple and easy to do and if it fails , saves you tons of hard work. A 5 min test.

Test 1:

First, make sure the valve opens cold by doing the digit finger test , it must move the diaphram ,when pressed, about 1/4" (6mm) and then go thunk as you release it. If not?, IT IS BAD or just dirty

See that metal ring at the base of the Black Diaphram below?. That part moves in about 6mm. In lay terms , it moves the distance of a pencil eraser size.

This device is nothing more than a vacuum operated air valve. (but operates with very hot exhaust gasses.)

It is spring loaded, so the valve most close by its own actions, if not?, it's bad. period.

Most Main valves packed up, can be cleaned and returned to service.

Test 2: STALL TEST actual)

Motor hot, 180F coolant or more.

Must be idling at 800 RPM. HOT. (if engine fails to idle correctly (racing idle speeds over 850 RPM HOT , that would need attention, and repairs before messing with EGR)

( this part is hot, I use a small wood stick (no tools?) to push this RING below, so I don't burn my fingers, but in truth, my vacuum pump is best. )

On this car , apply vacuum using a hand vac tool to the #1 main EGR valve nipple and pump it up to 8" inches of vacuum. (or press in the diaphragm with your finger, ouch !)

Here is a video of a man using the hand vacuum. tool and stalling (nearly) a 8v Sidekick. (this works on all suzuki sidekicks and Geo Tracker)

Really good engines, can run at a very low speed and not stall but does shake violantly this slow. 400-500 rpm?

The RPM will drop radically , mine goes to 500 RPM or less and engine shakes. so must yours ! Can go as low RPM on stronger motors.

If the Main opens and the engine doesn't come close to stalling or stall fully ,then the exhaust path is blocked. Somewhere.! Doing the bark test now, cuts this job (discovery) in half.

Many times, NO RPM changes, (bingo! stall fails)

While using the vacuum tool , do a diaphragm leak down test. (a text book test , for all cars ever made (pump it and it , and it must hold 8 inches HG for 30 seconds. a standard test) If this fails, the EGR main is USELESS.

If you can not excercise the MAIN valve, it is stuck, so remove it and clean it, or replace it.

If the valve is sticking open ( any) then it is bad or dirty ,there is a spring inside that forces it closed. If the valve does not snap back fast , it is bad.

If the stall test fails, then it is clogged or the paths to and from EGR MAIN, are blocked. (with carbon).

If the main body is cracked sucking air its bad.

EGR main Gasket?

If the main body base gasket is cracked or missing it will suck air,

If the gasket is made of cereal box top cardboard, then it will fail, with hot exhaust here) Felpro sells a great gasket Part # 71164 for a buck. , Letting the EGR suck air in ANY way, will cause lean fueling. (a very bad thing)

Photo 2: EGR MAIN. Vacuum tube not shown. This part is at the rear of engine, and at the rear of the intake manifold behind intake runner #4. WAY hard to reach. It has 2 , 6mm threaded screws.

Back side view the black areas are

the diaphragm.

Back side view the black areas are

the diaphragm.The metal ring in the center of diaphram is the PUSH point. (test point)

The Live test. ( I want to see the ECU command the EGR open and see the diaphram move)

This proves oout the vacuum and electric side.

(do not do this test until the above STALL test passes , or it's a waste of time)

Same with bark test, if bark fails, this test below fails and is a waste of time.

For sure the new moving wheel mandate for this test really sucks, I use jack stands on the rear axle and front tires both chocked.

The FSM use a 2 man way , were one guy spins the left rear tire. only. (even more tedious)

The olders 16v cars, none of this is required.

(there are two methods, the old not moving test and the new moving method.)

The whole EGR system relies on Exhaust back pressure from the catalyst converter to sense the load on the engine, the more load , more EGR flow. << a fact.

See my new live test failed page here.

- 1992 to 1993 only: (Sidekicks, no Trackers had 16v here)

- Get motor good and fully hot, 180deg.

F Min.. Normal

hot motor is 180F to 195F ! range, The Thermostat must be functional ,

no

exceptions.

- Rev the motor up above 2500 RPM and the EGR Main

valve must move more and more

as RPM rises. The Diaphram can be viewed easy with a

hand mirror.

- Starting in 1994 the EGR will not open unless the rear axle is moving (speed must not be zero) , this takes jacking up the rear axle, to do this test.

- The FSM shows using neutral /park and spinning the left

tire by hand (2 people, one at tire) and then do the Rev up live

test.

(not requied prior to 94)

Pre Checks:

All ERG vacuum lines not cracked, or misrouted.

The vacuum schematic diagram is under the hood, look up , see large white sticker. (EPA compliance sticker, in USA )

- IF EGR MAIN #5 is has a diaphragm cracked (do a leak down test on the diaphragm?) Use a hand vac. pump to test EGR main.

- The EGR port (ported vacuum) must apply vacuum to VSV1 or the port is clogged. or hose is cracked.

- The VSV VALVE #1 is bad, The ECU sends 12v to this valve (moving 94+) and if the valve dont open it is bad.

- IF the ECU fails to command the VSV 1 to open when racing the throttle then , you have a Dead VSS, if car is 94 or newer. This will cause a DTC for VSS , if true and CEL lamp will flash #51 and the VSS code DCT #24. Code 24 kills all EGR tests. 92-94 early cars dont need a VSS working to make EGR work.

- We now have vacuum to the EGR modulator nipple "P" becuase VSV 1 opened.

- I now pull the bottom hose to the Modulator and it must bark or go putt putt , or the EGR main nipple feed this hose is packed with carbon.

- If the path is clean at that nipple then the CAT must be missing, or rodded out.

- I than check for vacuum exiting the Mod and if it is modulationg vacuum well to the EGR main the EGR main must work.

- if all that works and the EGR retracts then the calif sensor below must be dead.

- The EGR CALIF thermo probe EGRT #36 senses EGR temperature rise. (ECU monitors this probe and detects the temperature rise as MAIN valve opens)

- Cat Converter is missing , making the EGR mod valve , fault. (it uses the 2 psi Cat back pressure to moderate EGR flow) NO CAT , NO EGR , end story.

- RARE FAILS:

- TPS

bad signalling WOT all the time causing the EGR to be dead

. WOT = wide open throttle signal cancels ALL EGR

action,.

BARK TEST:

This test, will tell you which side of the EGR exhaust flow is failing hard. (the head tunnels side, or the Intake manifold side.)

The EGR main is remove , showing 2 holes. One is hard plenum vacuum the other is exhaust port #4 feed.

The tunnel path has 3 fail points, (intake flange S turn, head tunnel and the #4 exhaust port bypass hole)

The other EGR base port, is Intake side. This has 2 fail points on the newer 95 and 5 paths to fail in the early engine.

I made this up the test and name and saves tons of labor if it fails.

It's real simple (the stall test 2 failed so....)

I look in main valve guts, main was not blocked, or was and is now cleaned by you and working (test it by hand) then you do the bark tests.

Cold engine is best , for safety, engine off at first.

- Main EGR valve removed. (see those 2 ports there, on the Intake runner #4? make sure they are not packed in carbon, just THERE.

- The Main valve is clean and parked on the work bench. (and

fully tested by hand and vacuum tests. then.

- I block the vacuum

hole in the intake EGR main port (hole

is near right fender), This is the suck side EGR base port, block

it with rubber cork or cut down wine cork.(improvise?)

- I start the engine, and the left port above, barks load ! This is TUNNEL port, GOOD, I don't need to ream the head tunnel and #4 exhaust port (COOL !)

- The back side is good. Stop the engine and remove that cork,, now find a rubber hose and try to fit it up to the cork port (suck) side, and try to blow air with lips, to this suck port by this indirect method, If impossible? BINGO, it's blocked.

- What to do if it is blocked, If late engine, just clean

pipe 50 and the back side of TB mono port hole. If

early engine, the whole intake Quad injector

ports most be removed to clean it.

Follow this procedure to test the VSV valve.

Starting in 1991 , the Calif, Water temp. switch below is no longer used. (ECU now mimics it with ECT readings and software)

Last, How to do the Modulator test.

A Typical EGR functional map: 89-90 and very close up to 98 (but with out water switch)

Some Fed 48 cars do not have the EGR thermo probe sensor #8, below and have a special ECU.

Drawing / photo 2: The EGR main valve. Number 7 above.

On some years, and markets (have no part #50) the EGR has injection nozzles cast in to the head and can be very hard to clean.

See the hidden EGR ports here.

The Part #50 system for EGR injection is vastly more simple , and clogs easy but is far easier to clean.

This port 1 is a high fail point on all 16v Kicks.

Look here and clean port #1 top fail point on all 16v motors, in USA:

Extreme cases:

Cleaning the 8v EGR may require removing the Intake and cleaning all the passages inside for EGR functions.

Cleaning the #4 exhaust EGR port, cleaning the EGR head tunnel on car. ( use gun brushes)

Strange Relationships:

On all years 89-98 , the MOD valve will malfunction, if the Exhaust Cat CONV is bad ,rodded out, broken up or missing. Same with port #4 Exh.

On some years 89-95 the ECU will drop to FAILSAFE mode and punish you with RICH and Retarded timing (power loss and horrible MPG) (not at idle)

On some early years 89 and some Canadian models there is no code 51 at all and no punishment. ( and other (nonUSA) marketed cars and JDM cars).

Starting in 1996, there is no punishement mode in the ECU. Just a CEL glowing away running. and code P0400s ( has 2 tests ,not one, and freeze frame shows which)

The EGR has a good side, it helps cool the valves when gently cruising down the road, and valves will last far longer .

(in years past it was an enemy (80's) , no longer, is this true)

What Kicks have the #36 dwg #1 California EGR thermo probe aka: EGRT.? I call it a THERMOPROBE, its just a thermistor.

Data Points (factory spec) for the EGRT: source Pg, 6E99 FSM. ( has a graph plot and test procedure)

212° F. = 11.2 to 13.6k ohms or about 12,400 ohms : Cheating the sensor: I use a 10,000 ohm (any watts) cheap resistor to defeat 51's. (for testing!)

140° F = 42.1-55.5k ohms.

68° F = 214-313.8k ohms (typical room temperature reading)

The 2 ways to test this part.

DMM connected to EGRT unpluged. ( on OHMS resistance range)

You see near 200k ohms cold, that is good

Then, get motor fully hot, then push up (I use vacuum tool) ,this opens EGR main. motor may stall, I see less than 10,000 ohms, it works. (use hands on throttle to avoid stalling)

test way 2:

I can also remove the main, see at least 200k ohms (200,000 ohms) cold? super easy huh? In your hand.

and drop the whole main in a pan of boiling water (cam stove time or?), and see less or equal to 13,600 ohms.

The EGRT must not be shrouded in carbon, (clean it)

and most times, if I attempt to remove the EGRT from the body of MAIN, it breaks. Get it clean then test it, most times, that works.

The FSM BOILING TEST, same as ECT ,IAT, and Thermostat boiling test. But get about 14,000 ohms or less. (special tanks to a contributor) below is 12.6 K on the LCD display.

PASSING TEST.

PASSING TEST.For sure wifey poo, in Church..... Pan is from "GOOD -WILL" store, for garage uses.

If the sensor does not come out easy, (don't break it)then do the whole EGR main , after cleaning the pit , it hides in, of all carbon IMPACTIONS.

Tricks for the tool-less or near, crowd? (no hand vacuum tool from "harbor fright" (pun), really>?) NEW !

Ok , I'll bite. (MODulator valve and live tests are last , & are complex) Using stolen vacuum technology, lips blows, lips suck and bypassing, (no tools)

One poster came up with, what I will call a virtual 1993 test (94/95 actual car) test, he jumpers a vacuum line from the TB top nipple directly to the EGR "P" nipple , bypassing the VSV.

Engine hot , gun throttle and the EGR MAIN moves, it not find out why first. (stall test passes) No Flux Capacitors and back to the Future.

This test takes just minutes to do , and one hose. If it fails, The Modulator is bad, dirty or i's bark tube "B", is dead. see step 13 below and on.

- All exhaust paths from #4 exhuast header tube to the early EGR Quad injector ports (or 1995.5 the TB monoport) clean and blow tested with lips.

- All related hoses crack free, with eyes, and blow tested, with lips.

- The EGR boil test above, $10 Walmart meter works.

- Bypass the Mod valve, with new hose $1 , from VSV to

EGR main. I then steal vacuum from the EVAP plenum nipple

right, next EGR VSV. and run that to to my MAIN EGR Vac,nipple.

- I keep this new hose pinched, start engine and it

stalls unpinched, This proves the EGR main works. Remove this

hose at the hard vacuum above and put it to the EGR VSV output port.

- #4/5 passes, so then disconnect my TB EGR vacuum hose (top center TB) and run it to the EVAP hard plenum nipple (stolen vacuum) this puts hard vacuum to the EGR VSV input port.

- Keep the MOD bypassed until is say so... (end of line

4 above)

- The EGR VSV input is hard vacuum (check that?) and , I next unplug the EGR VSV side elect. connector (it's locked don't force it) This causes the VSV to open and stall the engine,

- If not?, this VSV is bad. Bench test it now (see link)

- Ok , test 8 passes, car stalls or 400 RPM happens. hot.

- We have made it to step 12, nice progress...

leave the EGR VSV top vacuum input hose connected to the

EVAP live sucking plenum vacuum nipple. (this trick, makes testing

1994+ EGR easier)

- I then, put back the MOD valve bypass fix to normal.

EGR VSV is bypassed to hard vacuum. We check the more complex

part of them all, the MR. EGR modulator.

- The MOD valve must flow air from P To Q with

lips, MOD removed. (on suzuki the P and Q are just a pipe with air

bleeds. there is no P>Q vacumm main orifice here, like on Toyota's)

- The Bottom MOD nipple, larger (I call it the bark

nipple) I then suck on

it (lips) and sucks the diaphragm, it moves in side against a

spring,

and then stops and it hold a vacuum, if I put my tongue on the B nipple

tip, it holds this vacuum, if not it's bad (a cracked diaphragm)

This is called the Classic, leak down test , not done with real

tools, just lips and our tongue.

- The MOD valve and it's filter and vent are

clean? , see below photo for locations and actions. Just bet the filter

up with thumping fingers, ok its good to go.

- The bark tube on the bottom of the MOD barks.(test 16)

if I, start engine, with this tube, top end of bark pulled

loose, ok, it does bark or, if not?, that path to the EGR is

blocked or the tube is cracked or clogged. This tube MUST bark, (a

pulse, at Exh. port #4 RATE !) if the Mod valve now works, the

MOD is good and the CAT is blasted to nothing, (DUST). EGR works of CAT

back pressures.

- At this point, if the EGR VSV connector pulled, the engine

does not stall (or near at 400rpm) The CAT must be bad. (blowing

in too the bark hose, on MOD, can prove the MOD works now. (tricky,yes)

- Ok it does stal,l using just the EVAP hard vacuum, into the EGR VSV port bypass trick, and EGR VSV connector pulled. If this show it works totally end to end but one factor. (next)

- The true live test, put back all vacuum hose now.

Gun the engine hot, and see the EGR MAIN open ; if car is 94/95 , then

you must spin one rear tire.

(drive shaft must spin, tranny can be in

Neutral for safety. The newer ECU's will not active the EGR at 0 MILE

PER HOUR. THIS CAN BE A DANGEROUS TEST , the

FSM shows how to do this safely. (turned by HANDS)

- If the EGR mod pulls in , with rear tire spinning, then all works now and drive and see if 51s clears. (reset it first with DOME fuse pulled for 1min)

Q means queer vacuum a better name is M, modulated vacuum. There are no Q words in Japanese. (Spoken) Quasi Vacuum? or Quantize.? is my best guess.

Ok, Quasi-moto says hey buddy, this is Quasi-Vacuum.

Above test are being tried now buy posters. YMMV, your modulator my vary. This part usually never fails, the diaphragm is silicon rubber (best) I do see the Red path clog some times.

In the below graphic the EGRT thermoprobe is missing, The bark tube is maked "to modulator" :: this drawing is generic, but very revealing.

This is the location for the thermal probe. See

Threads? The MOD bark tube is below that, and loves to clog fast.

This is the location for the thermal probe. See

Threads? The MOD bark tube is below that, and loves to clog fast.EGR totally packed in CARBON, use 16 penny nail to dig it out? or ICE pick?

A DIY vacuum test (leak down) Old school for sure. see above VAC nipple?

Ok, one more crazy tool-less test, push the diaphragm, open by hand all they way in, then put wet finger to nipple on the left, and last release the diaphragm, the diaphragm will come back a tad and freeze(stop) this act

creates a small vacuum inside and most hold fast there, or the diaphragm is cracked if it leaks down, and is bad. My last trick.. No more tricks..

This next photos is the Throttle body (late engine) Behind hole 1 is EGR side winder tube #50 .

The secret holes: Revealed. Mr. Mono port. This is never seen on early quad port engines. You can see , that I have identified each hole and its purpose.

#2 is Brake booster. (Photo by Bruce B.) thanks !

EGR ported vacuum is at hole #4 goes to that HOSE up top (EGR ported vacuum) That top EGR port, #4 only gets vacuum OFF idle,(ported)

The #4 hole is the EGR exhaust gas INJECTION point. (all that gas is only injected here) It loves to clog fast. (this engine lived in Failsafe mode, thus all that carbon crap there)

Ream out hole #1until it is 100% wide open. (see and get bare metal on #1 walls)

Some times, parts get mixed up between year cars in USA (only), this may help below;

DTC 53's (53 can mean ECU memory corruption or wrong EGR parts) 53's can be a Royal PITA !

NEW!

See DTC errors, #53 from H3LL here.

Conditions for the Code 51 test setup, & stage up and the failure. (all logic)

Key on , EGRT missing, code 53

Hot engine running. 180F + coolant. (ECT readings show hot)

Steady cruise, RPM not going wild, nor engine vacuum (MAP) bouncing for driver actions or ? no , malfunctions, say lean surge?

Not at IDLE , not at wide Open throttle. (the EGR VSV is open)

RPM, not too high or low ,say in the range of 2000 to 3000 RPM.

In 1994 and newer , the car must be moving faster than 0 miles per hour, MPH.

The ECU knows the EGR is open now, it opened it. (the ECU can only open the VSV , that is it.)

Option A: EGRT (Cal cars) or all 94 and newer

The ECU now does the test, it checks the EGRT for less than about 15k ohm's (15,000 ohms, my best guess here) if not? 15k,, it stores DTC 51 into memory.

Option B: Non EGRT cars (Fed cars.and non USA cars:

The ECU now checks RPM. for changes , and MAP readings ( ECU computes load at all times ) and can see the VACUUM drop at EGR open moment, if not?, 51s DTC is set.

end, ECU EGR monitor checks.

As always, pulling the DOME fuse resets all stored codes. (for a fast retests of the above)

The FSM has very sparce data. on this, 51's is mostly a USA DTC. Most other cars don't have this code, (Vitara's of this era) (I have like 20 FSM's from 20 countries on G16 and not one has 51 test)

The wheels turning rule is here.

revison 9---- 3-8-2010, new ecu pn table and year table for EGRT device cars ( some car engine and ecu swappers get in trouble.) minor edits 8-8-2014, added EPC links. new boil photo. 8-21-14

Adding lots of no tool tests , and tricks to do test, with no vacuum tools.