Part of the Electronic Fuel Injection System , aka: EFI

You do need 2 tools, The fuel pressure gauge and a vacuum hand pump (the latter has a vacuum gauge built in)

See Tools

The crack open a line and squirt test proves, only proves the pump is only spinning. (so does the buzz test)

These old cars no now failing FPR big time.

They love to stick inside, the diaphragm inside cracks, and the vacuum hose pulled off, leaks fuel. (bad FPR)

The vacuum nipple "source" can clog up, feeding this FPR vacuum hose. (need I say a cracked or missing hose?)

The tests are easy, if you check fuel pressure at 3 points, using hand vacuum tool, Keyon, pressure 1991+ and running pressure, and Deacelleration presssure (max vacuum)

I check 0" HG, 19" HG and max say 26"HG vacuum. (watching fuel pressure as I do that)

On the 1989/90 all tests must be done with engine running or cranking.

On other years, tests can be done for 3 seconds, keyon, repeated. (and for sure running)

Failures aplenty: ( when I say about 30 PSI , I really mean this exact amount here)

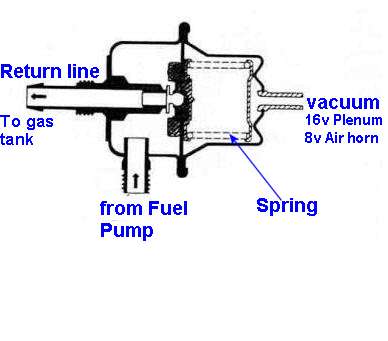

The 8v engine and 16v engine use 2 different type regulators. (not compatible.)

The 8v adjusts only for altitude. The 16v adjusts pressure at all throttle angles and altitude, this is because the injectors on the 16v MPI are buried deep in the plenum vacuum.

First off , I will show good fuel pressure readings and bad.

(A good fuel pressure and Regulation looks like this MP4 video) The example of bad , a hard system failure.\

There are many failure classes, dead, too low, too high pressure, and wildly out of control with no regulation and a leaking diaphragm.

The ECU (EFI Injection) in most cases, is totally intolerant of out of spec, fuel pressure or worse, no regulation. (the EFI must not go lean at W.0.T {wide open throttle}

Do not skip the 5 pump tests or more, as detailed here.

The purpose of the FPR is to keep differential fuel pressure across the injector at a constant. (this is a mandate (programming) of the ECU, it assumes this is working at all time)

This happens via the changing, vacuum at the vacuum hose. or in the case of 8v the change in Altitude at same hose. (air pressure drops at high alitude)

This photo is of the 8 valve regulator. (left and 16v right) FPR !

There reason there are 2 regulator for both engine, is the MPI injectors, are buried in the plenum vacuum, full time, but the 8v the injector is at air cleaner pressure, or very near

atmospheric pressure.

See the chart below for FPR action, Fuel pressure and Vacuum relationships.

The Purpose: "TO REGULATE"

The Fuel pressure regulator , is a pure mechanical actuator. The 16v mounts to the RAIL ,the 8v mounts to the front of the top throttle body horn.

This device regulates the fuel pressure at all times.

The ECU only functions correctly, if the pressure is correct for plenum pressure(vacuum) or altitude (8v only does altitude) All MPI enignes do both.

It actually keeps the pressure constant from the fuel side to the injector tip, this makes the ECU calculations far easier and is depended on by the ECU programming.

If the fuel filter is clogged up, this regulator my have great difficulty doing its job. (especially on hills , or heavy motor loads).

Doing the 60,000 mile tune up and filters, can be a blessing now. (aka; the service point schedule)

Look here for dead/weak pumps.

Fast tests: 8v TBI engine first.

(1.6L only) Doing all this with a clogged up fuel filter , a waste of time. Tune-up the car , ok?

The pump runs only ,for 3 seconds ,each key ON. (but on a 89/90, only cranking makes pressure, and some 1.8L Sports)

Key off:

- Connect

the vacuum gauge to the "FPR" baro nipple and (keys in pocket) and do

the classic automotive diaphragm leak down test

with the Mityvac(tm) tool.

- (if fail?, stop here and now, save all the below work, and

buy a new "FPR".) Ok, put back the vacuum line if this test passed.

- Connect fuel pressure gauge as shown HERE: I use the 6mm fuel

tap,

on the left side of the fuel filter.

- Key on, (nostart)

up to 3 times to see the maximum pressure. In

the range (band) of 34 -41psi

(8v)

- (if pressure is low, remove the gas cap)

- If pressure is 50 to 60 more more PSI the "FPR" is

jammed shut or the return line is smashed or blocked. ( pull the return

line

did pressure drop? yes, then the return line is clogged, if that line

pull action

fails?, the Reg is stuck closed and bad.

- If fuel pressure is too low?, block (pinch) the return line (if over 50 psi. the pump may be ok, but if Pump is restricted, or the pump sock clogged, you get a false PASS here.

- Just because a pump passes the dead head test (shunt test)

doesn't mean it can do FLOW. NOT AT ALL.

- Start the engine

now. Hot engine tests are best. 800 RPM or near.

- If the pressure bounces, do the same check at the "FPR"

baro vacuum port, there should be no vacuum on this hose or the air

cleaner packed up, like a brick.

- Ok , say, the pressure is near 30 running, and steady and GOOD , now lets us check vacuum re-actions. running.

- Pull the baro vac line, there must, not be fuel

pressure changes now, a 1psi uptick in fuel pressure, is ok. (dirty air

cleaner?)

- Connect this reg baro hose

, to a Mityvac (tm) nipple fitting and start hand pumping the handle.

- restart a dead engine, and use the tool to test the "FPR"

- Then, pump the hand pump, until you get to a real

high

vacuum. at about 23 inches-HG, on this nipple and watch the vacuum suck down

the fuel pressure.

- Note, as you pump, the pressure will reduce gradually and linearly, as you go, when running the pressure may be 34psi and drop real low as you pump.

- The pressure may drop so low the engine stalls. that is

ok. The normal drop in pressure. here is about 4 PSI fuel drop at

10,000 altitude or 20inches HG vacuum.

- This drop effect above, is less if you live at high altitudes. All comments are at sea-level.

- If the drop action is notchy ?or odd (not linear) the "FPR"

is worn out, and is sticking, after 20 years, that is par for the

course.

- If all these tests work correctly, the Regulator is

good, if the

pressure does not vary with changed vacuum , then the regulator is bad. (bad diaphragm

or jammed)

- A bad regulator is one, stuck too high or low is bad or

that does not

regulate with vacuum or bounces wildly all by its self.

On all 16v cars, the pressure will drop starting engine, is roughly 10PSI, 40 stalled to 30 it drops as the engine starts and pulls a hard vacuum in the plenum (19inches)

This Regulator senses plenum vacuum at all times, 19inchs HG at idle or near 0 HG at wide open throttle. And 25 inches, decelerating... fast in gear, foot of gas pedal.

In the end, the pressure must hold steady near 30 PSI running (both car), if not, the fuel loop IS BAD !

- Connect

the vacuum gauge to the "FPR" vacuum nipple and (keys in pocket) and do

the classic automotive diaphragm leak down test

with the mityvac tool.

- (if fail stop here and now, save all the below work, and

buy a new "FPR".) Ok, put back the vacuum line if this test passed.

- Connect fuel pressure gauge as shown HERE: I use the 6mm fuel

tap,

on the left side of the fuel filter.

- Key on, (not started)

3 times to see the maximum pressure. In

the range (band) of ) and 36-43 PSI

(if pressure is low, remove the gas cap)

- If pressure is 50 to 60 more more PSI the "FPR" is

jammed shut or the return line is smashed or blocked. ( pull the return

line,

did pressure drop? yes, then the return line is clogged, if that line

pull action

fails?, the Reg is stuck closed and bad.

- If fuel pressure is too low?, block (pinch) the return line (if over 50 psi. the pump may be ok, but if Pump is restricted, or the pump sock clogged, you get a false PASS here.

- Just because a pump passes the dead head test (shunt test)

doesn't mean it can do FLOW. NOT AT ALL.

- Start the engine

now. Hot engine tests are best. 800 RPM or near.

- IF the 16v fuel pressure bounces at all?, check that plenum vacuum, is not bouncing, if it is , the engine is bad. ( bad head valves, or cam belt slip or ?)

- If the engine surges, unplug the ISC to make sure its

not causing this surge before condemning actual engine.

- Ok , say, the pressure is near 30 running, and steady and GOOD , now let us check vacuum re-actions. running.

- When pulling 16v vacuum lines , be sure to block the

suction

hose side of pulled line (letting it suck air wrecks AFR fuel

mixers, too lean is bad on valves.)

- Connect this reg. baro

hose , to a Mityvac (tm) nipple fitting and start hand pumping the

handle.

- Restart a dead engine, and use the tool to test the "FPR"

- Then, pump the hand pump, until you get to a real

high

vacuum. at about 23 inches-HG, on then nipple and watch the vacuum suck down

the fuel pressure.

- Note, as you pump, the pressure will reduce gradually and linearly, as you go, if running, the drop drops.

- if the motor likes to stall with 0 HG, (it will be rich, ) then start motor at 20" HG, then change vacuum up and down to see the pressure changes around 20"HG.

- 20"HG simulates idle vacuum.

- This drop effect above, is less if you live at high altitudes. All comments are at sea-level.

- If the drop action is notchy ?or odd (not linear) the "FPR"

is worn out, and is sticking, after 20 years, that is par for the

course.

- If all these tests work correctly, the Regulator is

good, if the

pressure does not vary with changed vacuum , then the regulator is bad.

- A bad regulator is one, stuck too high or low is bad or

that does not

regulate with vacuum or bounces all by itself.

Check the diaphragm for leak down rate at the vacuum gauge dial, none is acceptable. (pump it to 8 inches HG vacuum ,it must hold at 8"HG for 30seconds)

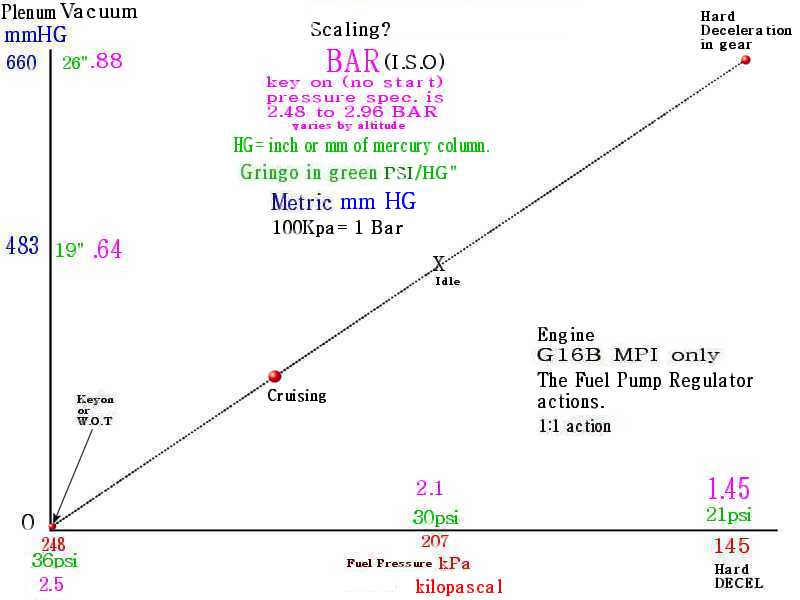

The VAC/PRESSURE Relationship graph MPI: (I just check 3 points on the graph and call it good)

The Below Graph, shows a new "FPR" with New key on (nostart) pressure of 36 psi. Grin'go means, USA strange measuring tools.(PSI?) (Most persons world wide, go, what's a pound?, is pound a kind of CAKE? or English money?)

The mmHG is relative pressure (not absolute) {using off the shelf mechanics pressure gauges} HG means column of Mercury. HG is the latin symbol for Mercury.(used in all periodic charts)

This looks complex, but is not, just check 3 points in the chart and call it good.

For example key pressure is 36, start engine, or use a vacuum tool (19"HG) and see 30PSI pressure, and then using a hand tool pull 26"HG or rev engine and cut the throttle fast to hit 26" or near to get 21PSI.

I made this graph, Suzuki thinks you don't need it , so skips telling you how to test it properly. (and if the valve sticks, the below facts prove this case)

The only hard part is keeping the fuel pump running, on a dead car. (running engines, are all super easy to test) See my 4 data points, X and the red balls.

MPI only in Graph #1

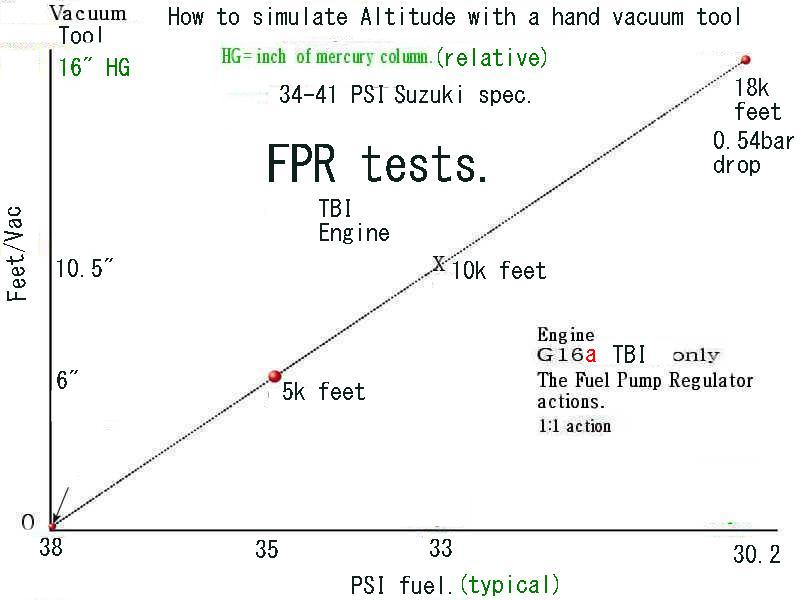

The 8 Valve TBI engine, the FPR works by altitude alone, and via hand vacuum tool can be tested just like the MPI enigne FPR

The 0 zero above, is 0" HG vacuum (vac. tool) and 0 feet altitude. As you drive car higher, the fuel pressure drops just like the above graph shows.

There is no need to test above 18,406 feet with the hand tool. (unless off road and a tad drunk? or on a DARE?) and has 1/2 the oxygen of SeaLevel; (so the ECU cuts fuel by 1/2 at 18,000 feet)

@18K feet is 1/2 atmosphere, or about 7.34 PSI (absolute). 0.50 Bar or 14.95 " HG or 506 mbar. or 50.6 Kpa.

Failure modes. (lots)

(it can in fact stick in any way it wants, when bad, they get old and wear out and jam up. hitting it can wake it up) I can hit many and FPR and it unsticks and works for a while.

Keep an open mind, we saw a guy that plugged up the FPR, so fuel pressure was max. to hide clogged up injectors, an amazing discovery, one guy put a ball bearing in the hose.

The fuel return line plugged, can also cause this same symptoms.(flooding) This condition can overload and wreck a good fuel pump.

Pinching the return line [an FSM test] (right side in photo) will cause the same thing and pressure will rise to near 60 psi.

The 58 psi is spec for this shunt test. Do this for only 2 seconds as this overloads the pump causing rapid heating. (mine hits 60 easy)

This fuel system leak down test, can catch leaking injectors ( common on 16v) there are other causes.

List of Failure modes: (and tests and symptoms.)

Stuck at 30 PSI (not regulating) the MPI goes lean WOT. The TBI goes, rich.

Stuck closed at 60PSI (both cars go rich and flood and the fuel pump is damaged, due to such an overload)

Stuck at 20 PSI, lean at all times. (ECU/EFI may hide this with Closed loop major fuel trim compensations but will not at WOT, the engine will bog there)

Diaphragm is cracked, so it can't move , so pressure runs high and rich.

A cracked diaphragm causes the 8v to fail it high altitudes.

The MPI 16v, fails at all time, in 2 ways , a nasty vacuum leak (lean) and high fuel pressure (40psi) I'm not sure who win there, but ill bet the 40psi wins for RICH)

The 16v is more complex, (diaphragm cracked) (lean at idle but to rich WOT) a psychotic state. And no regulation

TBI 8v will be too rich at high Altitude. (and ok at sea level because fuel pressure is good and there is no air leak to the plenum, like the above) the Mityvac finds this so easy.

A Bad Diaphragm:

Do a leak down test (VACUUM not fuel) on the Diaphragm, using a hand pump, Apply 20 inches vacuum to the nipple (small) above and see if it refuses to leak down in 1min.

Gas in side the diaphragm port can is a sign of a bad diaphragm (or reg) but on some 8v cars with cracked injector o-rings , gas does go right down the vacuum hose to this device.

Other facts:

Rapping a bad FPreg can unstick it. (gets you home, trick) Rapping things, can get you home, FPREG, FUEL Tank(pump) and Starter motor.

Doing a squirt test by cracking loose (open) a fuel fitting proves little, all THAT proves, is the pump is running and NOTHING else , only pressure/flows count.

The pump with only 6vdc arriving at its terminals (is wrong) passes, this silly squirt test and is hopeless, as does the FPReg stuck fully open or closed. Hopeless.

The squirt test only finds, dead pumps. 1 of 8 possible failures . (not too effective?) But sure , if no squirt, at all for 3 seconds key on, the pump is dead.

This EFI system is not a CARB. there is no float bowl to fill, only 30 PSI works not 1 PSI ! not 60 PSI, (60 is the shunt rating of the pump.)

I have cars and motorcycles carb engines, that run perfect at 1 PSI, EFI don't work right at low fuel pressures. or too high.

Forget carb ways and means. Most injector makers, state, that the lowest valid presssure is 20 PSI. (below that it is unpredictable)

Check the fuel return line, to be sure there is no blockage in the fuel return.(off road damage crushed the return line?) see photos at end of page for paths.

Make sure the gas cap has the stock vacuum breaker, if missing the tank will implode and for sure have low fuel pressure.(on a cooling trend day or long trips)

Loosen the gas cap, if pressures are wrong, or car stalls, and all symptoms point to fuel loss.

Not using a proper fuel pressure gauge to test fuel pressure at the rail or at the filter test port , is the number reason for wasted time and parts and dropped tanks in vain.

Spec: Pump pressures: 16v example: all numbers at SeaLevel.

PFreg = Fuel pressure regulator at the end of the RAIL.

There are 3 data points ( Dynamic tests) for all MPI engines, of this class G16 MPI. Sidekicks, Vitara's Trackers and X90s. ALl have G16B engine.

The first tests are , the FPREG is not leaking fuel to the vacuum port and that FPreg vacuum leak down test passes for 30 seconds, if not , its a bad FPreg.

What the SPEC FAILS to show and state is the 1:1 ratio rules are the KEY tests. Using a hand held vacuum tool ,makes the test easy. Very easy.

Keep in mind, key on air pressure 29" HG is normal @ Sea Level pressure or 0 PSI relative air pressure, and that this air pressure is near the same as wide open throttle.

You mechanics vacuum tool is relative pressure, and read 0 HG, just sitting in your hands or connected to a non running engine.

The 1:1 rule is simple , in that 1 psi vacuum change, results in 1 psi fuel pressure change. (the Reg drops fuel pressure with increases of relative vacuum)

- The keyon, max. fuel

pressure near 40 PSI. (36-43) Key on 3 times to get max. The

atomosphere is 29"HG absolute or as your tool shows it's, 0" HG.

- The idle fuel

pressure (19" HG) running.

(9.33 PSI vacuum)

- Deceleration fuel pressure, (26" HG? or 12.8 PSI)

- keyon 40 PSI Fuel

presssure (just 1 example) keyon.

( this is the regulation, of only the PFreg. internal spring

inside) (60 PSI is a stuck closed valve){below 36 is a leaking

valve.}

- idle fuel pressure drops

6 PSI to 34 PSI , this proves the 1:1 rule works here. This new

pressure, is vacuum controlled.

- Decel fuel pressure will

be a drop to 27 PSI fuel pressure. The plenum pressure drops 13

PSI ( 40-13= 27)

Lets pretend the key on (2 man one at key, one at gauge) fuel pressure is 40 PSI. (leak down test passes. that 40 is best key on pressure not dropped !)

Then you start hot engine and RPM is normal at 800 RPM, A/C is turned off.

What should the pressure be.? now.

The regulator is a 1:1 regulator in that a 1 PSI drop in air pressure (vacuum) causes a 1 PSI fuel pressure drop.

Using round numbers now. (more easy)

So, At sea level, plenum pressure (fpreg) is at 30"HG or 14.7PSI call it 15. then you start engine and plenum idling goes to (19"HG = 9.33 PSI) call it 9.

The plenum drops from 15-9= 6 PSI , so the fuel pressure drop is 6 PSI. (1:1)

The key on pressure was is 40 PSI, you start the engine and at 800 rpm hot the FPRreg will drop pressure 6psi. from 40 to 34 PSI. (use your own starting pressure here)

The regulator keeps pressure across the injector, the same at all altitudes and all throttle angles. ( the ECU injects fuel based on this same differential regulated pressures, in a loop system)

( this regulated pressure ,greatly effects wide open throttle and fast acceleration injection rates)

These sets of rules, are what I use to test the PFreg.

The MPI engine the FPreg must work correctly at all alittudes and at all throttle openings (both) If not the ECU can mess up fuel relates or not have full power. (go lean or too rich)

(the 8v work DROPS, the same way hand tested, but drops for Altitude only running, this is because the injector LOCATED on the Atmospheric side of the throttle plate)

8V example:

PFreg = Fuel pressure regulator at the front center of the Throttle body.

Sea level 29.9 inches HG, and at 10,000 feet its 20.6 HG inches, the conversion to PSI shows that to be 14.7-10.1 = 4.6 PSI drop. So fuel pressure drops that much too.

You can test this on any running engine, (gauge attached) and see this drop with a hand vacuum tool attached to the FPreg , nipple. ( vacuum hose blocked off, to plenum)

To use the 1:1 rule you must convert vacuum to pressure, so both sides are pressure.

Keyon atmospheric air pressure is 14.2 PSI. ) and is near this at Wide open throttle. The hand vacuum gauge shows, 0 inches HG relative.

I will use vacuum tool (relative) pressure here.

0"HG = full atomosophric pressure. and 26"HG is hard Deceleration.

The Deceleration pressures (vacuum) will be, near 26 " HG is (12.8 PSI) I pick 26 but can be more on a strong engine, with good valves and rings, it sucks real hard.

At key on time, not running the Air pressure is 0 HG or 0 PSI Relative.

As you can see, the plenum pressure can vary from 0 to 12.8 PSI (call it 13 in round easy numbers)

This means the FPreg test using the hand tool tests, must do the same, the 1:1 rule, not mentioned in the FSM.

That means at key on of 40 PSI fuel pressure the pressure must drop with a hand tool, by (1:1) 13 PSI to 27 PSI.

If not?, the FPreg has issues. (leak down test fails or is leaking, at its fuel valve or is stuck)

The 8v must work correctly at all altitudes.

1996-98 FACTORY specifcations: 16v MPI , G16B (FSM pages, V1-pg6e3-c2-12)

The spec, kinda sucks, (pun intended) as it should show the effects of altitude and does not, it mixes this fact and part variances, as one set of numbers)

30-37 psi running ( the drop must pass the 1:1 rule at all times, they forgot to say)

36-43 key on , not running.

Fuel pressure leak down drop test (cut key test) is drop to no more than 26psi , after 1 minute (mine don't drop at all, for many long minutes) This test proves the vavle is not leaking.

Gringo: This is the odd HG practice, in USA of , using imperial inches, and using toxic mercury to measure pressure (LOL), the ROTW (world) uses BAR and kPa)

Best tools to use: $$ Good old Harbor Fright (a pun) More tools here.

Vacuum HAND PUMP at Harbor Fright ! (pun name)

A Fuel Pressure gauge, that is cheap and fits Suz. perfectly. (see hose on right , fits our filter port perfectly, gauge is poor, but the hose is primo!)

Pressure gage. the hoses fit all Trackers and Sidekicks.

I only mention HF tools , not because they are good, but for skin flints (no dig) and they will ship country wide. 400+ stores in USA

I've seen this tool come out of the box and the needle had fell off....

The hose that comes with this tool fits the suzuki perfectly and would be hard to find.

The tools at HF , can have very poor instructions, so I you need good instructions , get a real tool at a real auto store. (I have a page just for the cylinder leak down tool)

Loops: The 8v loop

The 16v loop: (the 16v also has filter test port, saving the cost of the port adapter)

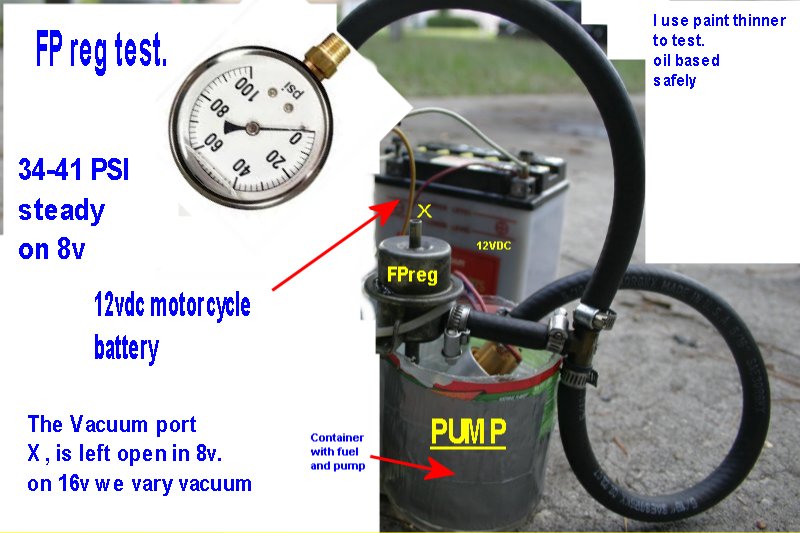

The FPreg can be bench tested (back yard , please) for full testing on the bench , apply vacuum a the yellow X.

You can also buy fire proof injector test fluid, like the pro-injector-cleaner, shops use.

The Fpreg return line is not seen below, it just shoots, test fuel, into the plastic bucket. (coffee can?)

The parting shot: or keep and open mind when testing, anything is near possible , in the real world.

The owner of a G16 8v Vitara (Kick real name) drives with black cloud everywhere and 10 MPG. 23.5 Liters/100km ( gas is not cheap)

We find that the fuel pressure is too, high, and as usaully nobody in this country (S.E, Asia) ever heard of a Vitara, or a pressure guage.

After barrowing said gauge the pressure is discovered at 50psi.

Every thing is checked, and last the above FPreg. (due to "tool-less" status)

After much fiddling etc, we see the PO (previous owner, mad?) took some hard wood slivers and jammed them, inside the , fuel inlet port, such that, it jammed up the spring.

The Previous owner had dirty clogged, injector(s), instead of cleaning it, he molested the PFreg to have huge fuel pressures.. Amazing...what folks will do.

Ordering a new Fpreg from 10,000 miles away, was the cure. (and injector(s) fully cleaned car runs like new.

ver 8, 10-9-2010 , and 4-25-2013 ,spit the page. 8v and 16v, added loop photos and bench test.