THE FUEL PUMP Tests: 1989 to 1998

You are here because, engine is bogging , flooding or won't start.

Check these quick test items first (easy)

- Drive with gas cap loose, does it drive ok, now?, that is a bad cap or is wrong cap (it must have a working vacuum breaker inside)

- Remove FPR

vacuum hose,

see gas drip out of hose ,that is a bad FPR. (cracked diaphragm)

The FPR is now very old and loves to stick inside, causing a fixed

pressure (bad)

- 16 valve MPI only ,With same hose removed, do you get vacuum there running? if not the nipple on front of plenum, to said hose, is clogged.

- Some cars, (mine) you can not hear the pump

Buzz keyon, because it's just too quite. (I must check

pressure with gauges, and voltmeter to pump wires for 12vdc.)

- Some cars 1989 and 90 for sure, the pump does not run keyon, only cranked or engine running , for the pump to spin. (and same with J18 engines. 1996-98)

- Running any car with a clogged fuel filter, assures early end of life for any pump, pumping into a dead head. A new fuel filter now, can save your pump and get full pressure to the injector .

- The 2 door car, fuel pump ground, loves to rust behind the

left rear tail light housing and the ground screw there. Lost

12vdc to pump cranking?

Do you run a custom external fuel pump and forget the rules?

Do not hot wire the pump RELAY or you will blow up the ECU, if you short the relay pins, just for an instant, the ECU just bought the farm. SMOKE CLOUD!

The pump must work right (about 30 PSI running) and the regulator "FPR", or the EFI system working correctly, is hopeless.

In fact, getting the Pump and Regulator working right is #1 EFI checks.

The ECU can NOT measure pump pressure. Not on these old dog cars.

This system is a loop system and not a dead head system, as seen on all newer cars.

The FSM covers all test.

HOW DO I GET CONNECTED to my fuel gauge?

Warnings and hot links to focused topics:

If you use the wrong gas cap, the tank will pull a vacuum (bad) and stall the pump , starve the injectors. or worse implode.

- Jump to all tests NOW:

- Don't let a bad FPR regulator fool you!

- The injector balance and leak down tests are on a different page.. here...

- I know for sure the pump is bad page.

Do not RUN the PUMP dry, it IS, "fuel cooled and Lubricated ! "Not even, for 1 second!

If you must bench test it , not submerged in gasoline , use a pan of paint thinner (and oil based Stoddard solvent).

Do use water to test as it will rust the check balls in side, (bad idea)

Before removing fuel parts , DO NOT FAIL to Depressurize the system and follow all safety rules on this page.

I use this Test Gauge, that comes with a real SUZUKI 6mm HOSE adapter.

THE ECU/ECM/PCM ASSUMES FUEL PRESSURE IS IN SPEC. !

The fuel pressure REGULATOR "FPR" MAKES THAT HAPPEN running.

On the 16valve engines (all MPI) the FPR , decreases fuel pressure at higher plenum vacuums, so the injectors can flow properly.

[ 8 valve TBI and 16 valve MPI , Sidekick /Trackers ] { Throttle body Injection and Multipoint Injection}

This page, in no way, replaces the FSM, nor tries to compete /replace, with the fabulous " AA1Car.com !"

The Buzz test: (1991 to 1998)

If you have no buzzing sound, at the tank filler cap at key on for 3 seconds, then by all means check the ground and power at the harness HERE:

1989/90 the pump is dead key on (and the J18 engine Sport,)

The 89/90 will not activate the pump key, on unless the air temp is below 10 deg. F.

Best is to crank the 89/90 to be sure fuel pump relay activates. (or hot wire the pump at left tail light housing shell, at the pink wire)

SAFETY:

| Safety

first: [ no open flames, 2 fire extinguishers at hand, lots of

fresh

air , parked out doors.] WARNING! GASOLINE IS A HIGHLY FLAMMABLE AND DANGEROUS SUBSTANCE! Keep gasoline away from ALL heat sources! No Children or wandering curious people around car. Keep Extinguisher to rear of car , at least 25' or so , at hand, but can be grabbed NO MATTER ! A fuel rated Extinguisher is mandatory ! A beach towel or small blanket is good too. Just in case. If you have smokers in your local, tell them to stay the heck away from you and your car. |

I am NOT recommending Gas system tests , I am reporting what others have done.!!!

Warning !, if your car will not start, you can't drain the pressure , so it will spray all over the place !!! Have lots of rags, goggles on, and a field to throw the rags, FAST !

Drive a 16 penny nail in an old tree, and hang the rags , away for the curious and innocent. ( and ignition sources)

Do not do these tests ,unless you understand the issues and have the proper tools , including a real fuel pressure test gauge set.

THE BLEED DOWN !

How to purge the gas from the Gas lines: { MUST BE DONE BEFORE WORKING ON THE FUEL PRESSURE SYSTEM }

READ the procedures here.

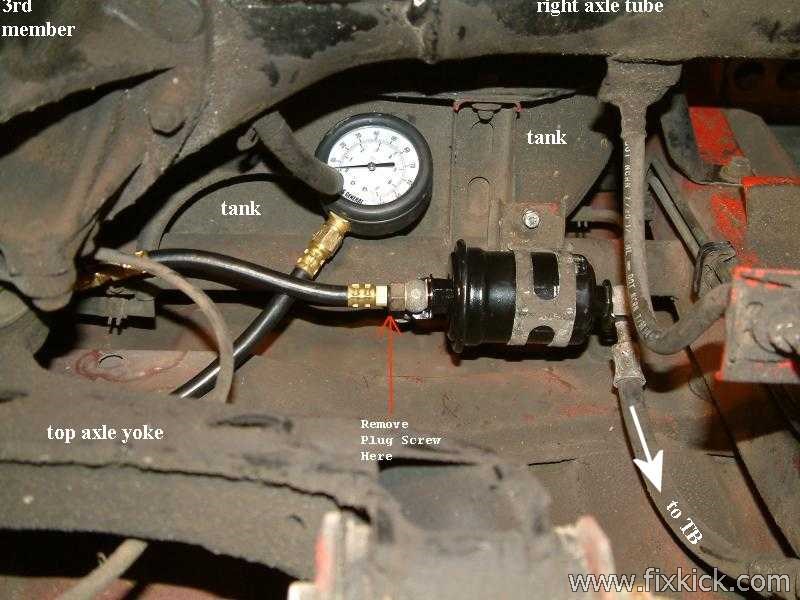

Getting Fitted ! (all Sidekick's 1.6L have a test port on the filter banjo fitting) {And Trackers} G16A/B engines.

The below tools is from Harbor Fright(pun) and comes with the 6mm Suzuki Adapter. (worth every penny just for that hose)

This Harbor freight tool works out of the box. Nothing else to buy for play with.

See the banjo fitting (Suzuki stock) in the photo on the lower left?

click

to zoom

click

to zoomThis below adapter will convert the banjo fitting to NPT 1/8" threaded hole, so ANY gauge will fit the fuel filter Banjo.

RUS-640700

Banjo with 1/8" NPT test port for all filter banjo's up to 1998

RUS-640700

Banjo with 1/8" NPT test port for all filter banjo's up to 1998With the 4AN schrader valve, or with a 1/8th inch NPT pipe cap and or nipple added.

NPT is National Pipe Tapered thread . (USA pipe theards, is not metric)

The 16v cars, you an fit up, two ways, the above hose at the filter or at the fuel rail, seen next.

G16B MPI method 2: MPI fuel rail.

Some mechanics.s like to convert it to the new car style , for that , I offer the next link.

How to use the fuel rail test plug or where to get the high quality adapter for this fuel rail.

16V Schrader valve (aux. fuel rail) ad. (all)

PUMP Testing Overview: AT LEAST DO ALL the 6 checks. And then an MPI only injector balance drop test #7 .

Before we start, let me state the 9 tests, that can be done: (there are 6 more tests on a set of 4 MPI injectors, see #7 )

You are testing 3 major parts here, the pump, the FPreg, the Injectors. Using just ONE TOOL. A $20 TOOL.

You must do the ones in RED ones, for sure ! steps 1 to 6 can all be tested with the fuel filter banjo 6mm tap port.

This is not any Carburettor. My CARB's will run with 1/10th PSI fuel pressure, in fact will run with only GRAVITY pressure (like any older motorcycle with a carb does)

This is EFI, the Injectors will not work right below the industry standard min. 28 PSI.

The fuel filter is clean and fresh or all this is just tears in the rain. By the way, clogged filters kill perfectly good pumps. (overloads it)

Never fail to do test 1 to 6: if a 16v MPI engine, never fail to do the #7 balance, test to find weak/bad/clogged or leaking injectors.

(The 8v TBI you can not do a balance test with 1 injector, but you can do a single leak down test #5)

These are all FSM CLASSIC BASIC tests. (#8/9) are for hard luck cases.

Test 1 is just pure mechanic know how, it's fast ,easy, no tools and has some value, The squirt/dribble test, finds 100% dead fuel pumps, (do it cranking)

Warning ,some Suzuki engines, need to be cranked to get the pump active (pre 91s, and all J18, J20 engines. and more, I don't know)

All G16 engines starting in 1991, run the fuel pump or 3 seconds , keyon, only. USA spec. cars. (listen with your ear at the gas filler cap hole , uncapped)

6 tests are key and 10 with balance on MPI.

Pre-conditions, (fuses not blown, IG-coil or "FI") Take of gas cap, listen for buzzing for 3 seconds each key on (this test fails to work 89/90 by design , and we cant hear the pump cranking)

Check engine light glows key on , if not ECU is dead and pump relay same.

Next, remove the return line at the FPreg, "FPR" key on and it must return fuel. (in 1989/90 you must crank to get pump active)

If the engine will not start. tests 4,5 are impossible to do, (near) test 6 can be done by turning key on 3 times (or 89/90 cranking). Test 7 can be done on a dead engine. (using keyon/off method)

Any fuel line can be cracked open from fuel filter to FPreg or Rail plug on 16v. Some call this the dry rail test, if dry cranking the pump is not working , bad, or has no DC power.

All years 1991 up , the pump primes to 34-36 psi for 3 seconds, each keyon. G16 engines. (same J18 engines do not , and act like 80/90) If no prime happens, check for 12vdc at pump wires at rear bumper.

- The TIME Honored, crack a fuel

fitting to see of fuel pressure is

there, test. It if squirts, that

means little at all. Only no dribble, means

something. (89/90 takes cranking here)

- Static Pump test .

Key on , no-start engine, pressure, (repeats each keyon) 89/90

must be cranked. see SPEC sections for

pressure ranges below.

8v = 34PSI min, 16v = 36 PSI min.

- Residual Pump test. A.k.a: The leak down test, you cut the key to off and time the pressure drop to 25 PSI, most hold for 1 minute or way more. see how below)

- Engine

Running

Pressure,

the pressure while idling. Stays same on 8v but

the MPI pressures change at all engine loads, seen here.

- Fuel pressure Regulator

test, See fast checks here.

Here is my FPR full

test page.

- Dead Head

SHUNT test. key

on , running ,

block the FPR return

line. (see 60 psi

is typical , for just 5 seconds shunted). [ test is hard on

pumps,

so a short time] finds weak pumps.

- G16B

MPI 16v

Injector drop or balance test. 1992 and newer.(called the Injector balance test) There are 3 ways to do it.. Click here to

see all ways, and means.(off site)

- Fuel Volume test ,

fill a bucket with a stop watch or use the fancy gauge shown

below. The Pump does 60 LPH (liters/hr)

or 1/2gallon in a bucket in 2 minutes.

- Scope test , place any scope across the Fuel pump power terminals and look for pump noise at Duane's world. To much noise indicates pump internal brush failure. (it WILL die soon)

The real $uzuki book'$ cover every step perfectly.

Elaborations of these tests:

The RESIDUAL test #3 (the leak down test, best name) can fail for 3 causes ,with a bad check ball in the pump, bad FPR, fooling you that the injector leaks and does not.

If the Residual test fails, unplug all injectors, fail now? no? the injectors are leaking.

The Residual test is easy on all 91 and newer Sidekicks, G16s , you have the fuel pressure gauge installed, and you key on 3 times and see normal pressure , stated in the specs below.

Then key off, and the pressure holds for a minute. (above 25psi) My car holds like a rock.

If not? unplug injectors, then Pinch the return.

Pinch the FPR return line if pressure holds above., the FPR is bad. (leaks inside or is jammed inside.) See the injector page for how to find injector leaks many ways.

If both those fail to stop the leakdown, the pump check ball leaks bad. making injector tests very hard to do (impossible)

On TBI if you LOOK at injector with EYEBALL and if it or the Injector o_rings leak fuel, they are bad.

The FPreg ("FPR" can be bad and stuck open inside. (easy to find, block return line, if leaks ends, bingo bad FPR !)

The G16b MPI can leak 3 more ways 4 + 2 = 6 way. FPR, tank pump check ball, or any of 3 injectors (inside them) leaks. (or are stuck on, because ECU driver to injector is at 0v for any reasons)

If the MPI injector leaks, then we unplug all injectors to see if that lead down ends., and then look for wet spark tips. to see if the injector leaks.

One can block the fuel hose to rear of rail, to prove, the pump check ball leaks. (remove fuel supply line before rail or TB and block it)

One cute way, to see MPI injectors leak is the cheap $30 bore lighted camera ,sent down spark plug hole, set that cylinder to intake valve open , key on 3 times, does it flood? repeat on all cylinders.

Injectors all unplugged, first, if they leak only plugged in, the ECU is bad, or harness shorts.

Balance tests. (after the leak down passes, #5 above) Static leak test must pass to proceed to balance. (this is just a quick review, see links)

The balance test compares rates of flow. from 1 injector to them all. They need to be equal. if one is weak it's partially clogged.

The 3 ways mentioned above "16v balance" and covered on my injector page below link, are:

- Injector pulser box, (all injector connectors pulled the pulsed 1 by one, noting drop rate) << pro way. Here is the Injector Pulser unit:

- 9 vdc radio (smoke detector) battery way, (same as above DIY ways, 9vdc battery (weak) saves injector coil from overheating. (risky with 12vdc static applications)

- The Crank down test way, (one injector connected at a time and you crank it down with fuel pump relay pulled just before the crank down) (a difficult test to pull off, with 1 man)

All 4 injectors can clog or leak. If clogged 100% the balance test shows no pressure drop, at the bad one.

The injectors have 10 micron screens inside (cages) and if clogged, only back flushing can get them clean. Period. (and most need ultrasonic cleaning too)

The balance test finds, dead, leaky or weak injectors. (finds 1 weak injector very easy, if one other injector is good)

(if all injectors are partially clogged and equal , this #7 testing fails to see that, because this test is differential comparisons ,so clean them all) OLD BAD FUEL causes this.

The 8v TBI injector can be just viewed directly: (you can see it inject cranking, or running or see it leak)

89/90 must be cranking to get the pump active , you release the key and the injector must not leak (viewed)at the instant of key off , to the stalling of engine. (89/90 are a tricky lot, to test)

91 and newer , just Key on, gets full pressure and that it does not LEAK(viewed) under static pressure. (the injector or it's 2 O-rings that can leak , viewed live)

Remove the 8v Throttle body TOP Air horn PIPE and look, and then crank over the engine and see it inject, with your eyes. (all years)

If the 8v don't start and spark is good, look at the Injector tip.. cranking.... it must squirt greatly.

SPEC.'S (short for factory specifications "data" )

Rule 1: In each case the fuel pressure regulator FPR vacuum nipple must not leak fuel, (pull hose, and look!)

or it's a bad FPreg ! "FPR"

Rule 2: check that the FPreg. diaphragm is not leaking (cracked inside) with a vacuum tool.

Rule 3: The FPR with a hand vacuum pump attached, does this ( the rise in vacuum causes fuel pressure to drop)

The FPR this old, loves to leak fuel out the vacuum nipple, valve stick open closed or jams and the diaphragm cracks.

The G16A 8 valve Throttle body "single point" injected engine, TBI. (non MPI) 89/90 (ONLY).

The 8V TBI fuel pressures varies by ALTITUDE not throttle actions like 16v does. (air filter clean)

The FPR vacuum nipple is above the throttle valve. (not below as is the case with MPI) A Big difference that fact.

The below is factory spec. 1989 to 1998.

FSM: "factory service manual data"

The Sidekick 1989/90 see Page1 and Page2 You must crank the engine, to get any pressure, these 2 years only.

1989/90 = 34.1 to 39.8 PSI. Key on cranking and idling. (keyon does not build pressure 89/90 years only))

GM shows this spec. as: 34-41 PSI. (do not exceed 41 )

Residual test is 25 psi min. after 1 minute. (at key turning off) aka: Leak down test.

This Shunted pressure is near 58 psi. [or more] (blocking/pinching, FPR-reg return line) aka dead head testing.

The 8v cars, all the FPreg (FPR) only changes pressure for altitude, but a hand vacuum tool can see it drop pressure 6-10psi.

The tech, always uses a hand vacuum tool to see if the diaphragm leaks and then using the fuel pressure gauge sees that the FPR, varies fuel pressure no less than 6 PSI.

Say you get 37 PSI, so you apply 26 inches of vacuum and it must go up by 6 psi pressure, the ratio in metric BAR is 1:1. 1 bar air pressure(vacuum) causes a 1 bar fuel pressure change. (at sea level)

The 8 valve Throttle body injected engine, TBI. (non MPI) , yes, more SPEC.'s

Fuel Pressure specifications for 1991' to 95' TBI and MPI. (ONLY)

Starting in 1991, just Key on (only), runs the pump for 3 seconds. (you can repeat this over and over to build pressure)

Data: I'll not repeat this data, just look at the real deal.

1991-1995 8v TBI FSM Quotes: (34 PSI minimum)

The 8v TBI FSM 1991-95 flow chart , diagnosis page.

This engine works different than any G16 8valve TBI . (key on primes the pump these years)

1992-1995 16V MPI FSM Quotes. (30 PSI minimum)

The fuel pressure must drop on this engine from keyon to running per the FPR graph below.

Fuel Pressure Regulator (FPR) tests:

For TBI and MPI engines. It's a 1 Bar FPR.

Do the 5 tests, there, diaphram leaks air, nipple drips fuel and 3 test data points on the Graphs there.

THE Pump RULES:

Fuel pump is "ECU Commanded ON" , with, "key on", The ECU controls the pump at all times! (no crash and burn rules "logic")

- Key on (only) Injector prime pulse very short to purge

air. ( don't

expect an injector squirt, now , or on anything at all on any 1989/90 kick)

- Key on, hear 3 second run time of pump

(1989/90 needs to

be cranked, same on 1.8L Sports

or the pump will not

RUN) You can hear the pump run , 1991 to 1998.

- Engine Cranking, the pump is on for full duration of

the

cranking event. The pump receives 12vdc and you can hear it. (ear to gas filler hole)

- Engine Running , pump is always on, so long as Spark feed

back

(Tachometer) is

active and CMP is pulsing. You can not hear the pump over the engine

noise.

There is one more exception the 1.8L Sport DOHC ECU has a TSB ECU ROM upgrade, that changes the rules on the pump, in that it runs key on. only, for 3 seconds.

Almost all SPORTS, do not have this pump upgrade.! It is a very RARE car ,in the USA and Canada.

Designed IN SAFETY:

This seemingly strange behavior, is to prevent excessive gas from being released in to the engine or ground , causing flooding, hydra locking,, fire and pollution to our Air, or during or after a crash.

Some people, in some cars have actually pumped gas into the cylinders and hydra locked the engines , destroying them.

(if you or ECU injects more that 55cc of liquid fuel , to one cylinder, you will bend the rods.) (I CC heads and know this number)

(In extreme cold weather this can happen, cranking like a mad man)

Some ( DIY wizards) decided to defeat the Fuel pump relay( jammed it closed) and now have a fire hazard car, and can hydra locked the engine very easy.

This will never happen on a stock Suzuki. DO NOT HACK THE FUEL RELAYS !

Do not hot wire the fuel relays or socket or risk blowing up the ECU relay driver transistors, so very easy. This ECU control line must never be hot wired, (a $400 mistake)

Errata Online ,etc:

Many online sources , the AxxZone , etc, fib about how the 89/90 and Suzuki Sports work (fails to say , you must crank the engine) got zoned?

I found only the real Suzuki and GM/Geo FSM are correct and Mitchell's online, to get these facts right.

One other great source of facts is alldata.com

Factory service DATA !

For the 16V MPI , up to 98: (1.6L only)

Use this $10 adapter in place of the 16 Valve front fuel rail plug.

http://www.egauges.com/vdo_indA.asp?PN=ATM-2267

92-95 FSM specifications on RAIL pressure.

Warning the FSM fails to show what these number really mean (it's FPR regulated at all times)

The fuel pressure must rise or lower like the above chart shows.

Static test: 1.6L KEY ON-no start no plenum vacuum---Suz 35.6–42.7 psi (GM says 36-43 psi) Sport = 1.8L ----38.4–44.0 psi

Running pressure: . 1.6L Key ON-start - full plenum vacuum-- 29.8–37.0 psi (GM says 30-37 psi) Sport = 1.8L ---31.3–37.0 psi,

Both tests above are critical. to proper MPI operations.

The injector leak down test (simple and crude)

Residual pressure test: 1.6L YOU Key off , min. 28.4 psi for one minute. (leak down spec) , (GM says 26 Psi) Mine holds steady for 1min, no drop at all!

1.8L is the "Sport" model engine with a DOHC engine.(1996) The sport need to be cranking or running to get pressure. (not reflashed, see TSB for facts here)

96-98 16v FSM specifications Rail pressure: (pg.6E3-A-36-37)

Static: 36-43 PSI, keyon, not started ( you may have to key on 3 times to build enough pressure, pump runs on 3 seconds)

Running: 30-37 PSI , idling.

Residual :25 PSI , after 1min. drop test.

Testing ways and means...

( the ECU can hide bad fuel pressures, do not checking and correcting this now, IT WILL Fail soon !)

The pump tests:

There are many ways for it to fail.

The PRESSURE MUST HOLD AT SPEC. PRESSURE CRANKING AND RUNNING. Spec pressure is clearly stated above.

If the pressure drops below spec, there is a serious problem.

8v not drop below 34PSI (@sealevel)

16v not drop below 35 keyon, or 30 running.

The 16v, the FPreg, drops fuel pressure ,at higher plenum vacuum. (deceleration in gear)

The 16v , the FPreg increases fuel pressure, as you go WOT. (wide open throttle)

The 8v only drops PRESSURE for higher altitudes. (only this way!)

No matter which engine, at idle both must have a steady, regulated pressure near 30. (sea level)

If not?, you need to correct that now. The Below, is the prime suspect with no regulation.

The fuel pressure regulators can wear out and jam open or closed or WORSE.

Perspectives:

The pump at 60 LPH, puts out 2 or more times, what the injectors can squirt at 80-95 Horse power loads.

So the pump must be pretty bad for pressure to drop. or at 6v not 12v, as many are discovered.

Low fuel pressure?:, (at Throttle body)

Bad FPreg. or leaking, (stuck open)

Bad/weak pump (many pumps are good, but the wires (and connections) are bad to it. In many cases.

Pump is bad sucking excess electr. current (4amps is normal) overloading car wiring.

Normal pump voltage is 11v to 14.7 volts. never less , cranking or running.

(or clogged fuel filter or the pump in the tank has a clogged screen bottom sock)

The upper pump hose (in tank) can crack and cause horrid , fuel pressure under heavy engine loads.

Low pump voltage. (repeated, due to every-ones failure to look)

Too High Fuel Pressure?:

At filter test port 6mm test banjo fitting !

Bad FPreg. (stuck closed) or ruptured diaphragm.

Vacuum hose on 16v FPreg., fell off, or is clogged?

A Clogged Fuel filter. (seen as 50PSI many times and is too high. )

FPreg., fuel return line pinched or crushed or blocked. 60PSI is possible. (from FPreg all the way to the tank return port)

The residual test fails: (leak down , key off, natural pressure fall off drop test, failing can be...)

The injectors are stuck open. (bad)

The Pump check valve is stuck open (bad) (top of pump)

The FPreg. is bad or stuck open or leaks for any reasons. (just keyed off)

The Injectors are unbalanced, or dead or acting odd.

Offsite: The 8 step plan for testing the whole fuel system.

Offsite: Completely lost?, try this document:

Both the TBI car and MPI car, both use a closed fuel loop system.

The FPReg (fuel pump reg) holds pressure at 30psi (about) idling.

Many cars, If I see 50 psi running, then the filter is PACKED solid, zero maintenance cars, eat pumps up. (overloads it) (seen at filter test port ,here)

8 VALVE 1.6 LITER 1989 to 1995

(don't forget the 89/90 only pumps fuel cranking ! and running but never just KEYON)

TBI Fuel map: (throttle body injection)

If the leak down test fails, the injector is leaking, the o-rings are leaking , or the FPR is leaking, or the check valve (not seen) in the pump is leaking.

By pinching lines you can find who is leaking.

If I key off and pinch the return, and the leak stops, the FPR is no good.

You can , pull off the air horn MAIN PIPE and look at the injector see it leak , keyon , or fail to inject running or cranking at ANY TIME.

The FPR here is for altitude compensation only. so reads about 30 PSI running or not.

If filter is new and you get say 60 psi, the PFR is bad , or the return line is pinched (4wd impact damage? LOOK) (pull return line and test, or rap side of FPR)

The tank cap just have a vacuum breaker and if not, the pump WILL STALL.

( I avoid 12v battery hot wiring on all injectors , on this 1 ohm injector , 12v applied blows up the injector to smithereens in a flash)

( I avoid 12v battery hot wiring on all injectors and all ECU's)

The test port is 6mm x 1.0p (p = thread pitch)

the FPR vacuum line is not shown.

1992 to 1998 1.6L

MPI fuel Map below:

Has 16VALVES, (keep in mind the gauge can be at the filter , exactly like above, both cars, have same filter test port)

The same rules here as above comments. Leak down must not leak down for 1min. (find the leak first)

You can have clogged injectors or leaky injectors. The full testing of them is covered here.

The below shows 1 injector , there are 4 that can leak.

This tests is the leak down residual test. I'm seeing any thing leaks at all. there are 6 things that can leak.

4 injectors, FPR and the tank pump check valve. (if the pump check ball leaks, all tests become impossible to do, here)

The injectors, can all leak or just one. (if it leaks, unplug all 4 injector elect. conn.'s , still leak? (no , bad ECU or wires to same)

One injector or 4 can clog, this fails the balance test. (if all 4 are clogged, the balance tests shows no drop at all,) {< this is a short review see link above for full}

The balance test can be done 3 ways (#1- 9v transistor battery) the #2-injector pulser, or the #3-crank down test. (number 3 is very tricky test, see link above )

( I avoid 12v battery hot wiring on all injectors)

The crank down test , is crank motor with only 1 injector connected. and the pump relay pulled. (takes careful coordination )

short take:

(I see 40psi?, key on 3 times. I pull the fuel pump relay, (or pull the left tail light plug pulled for pump "pink wire") then i crank the motor

this injects one injector and Ii note the time to drop to near zero.

I repeat that 3 more times, do all 4 leak down at the same speed? (time) (using an injector pulser works best)

The below gauge is connected to a Summit racing adapter.

The FPR drops fuel pressure from 40 to about 30 psi with 8 inches of vacuum applied. The injectors are inside the plenum. and that is why the FPR works

different than the TBI above.

The tank cap just have a vacuum breaker and if not the pump WILL STALL. (loosen cap on tank and try 1 more time. then get a real cap)

The injector coil is 10 ohms and gets hot, with 12vdc applied full time, I'd avoid that idea. Use a pulser or a 9v transistor battery.; (radio battery)

The injectors is fuel cooled too. so...... if dry , gets hotter faster....

( I avoid 12v battery hot wiring on all injectors)

The 16v MPI system below:

Note : the Vacuum line is missing on each FPR in the above photos, but it is in fact there and connected. (& none the less, important !)

Warning:

The false sense of a good fuel pump system, due to passing, the above 6 tests.

If there is any restriction in the system the pressure may pass with flying colors. ( in extreme cases only).

Restrictions, mostly, do not reduce pressure ,they reduce flow and that only shows up at full engine load.

Watch out for flaky FPR . (or pinched fuel lines)

Replacing the Fuel filter and validating the full range and functionality of the FPR (regulator) is paramount to success.

Using an OTC 7416 can be used to check full flow.

THE VOLUME TESTER: ( almost never needed unless, desperate to the extreme) I show this for completeness.

I use a bucket, 1/2 gallon of fuel lands in bucket in 2 minutes flat (at pulled FPreg hose, in to said bucket ) is DIY way not tool below.

The pump is rated at 60 LPH (liters per hour) so divided by 60 that is 1 liter per minute. (in gringo; that is, 1 quart a minute)

This single test passing, does not prove a good pump.

This information should get you on the way, to having proper fuel pressure.

How to Upgrade your Fuel Rail to have a

Schrader valve and the new fuel rail plug we found.

How to Upgrade your Fuel Rail to have a

Schrader valve and the new fuel rail plug we found.FUEL PUMP Electrical testing and geography !

You know its not pumping right, for sure is dead for fails Say, the shunt test #5 .

See here for my , I'm sure the pump is dead, but want to know why?, page.

Keep in mind, about 1/2 the pump failures are not a bad pump, just bad wiring to the pump, end to end.

Use a voltmeter and make sure 12vdc makes it to the pump and that the pesky 2 door car, has a good pump ground behind the left rear tail lamp. oops !

ADVANCED INFORMATION:

Modification's and sources for gauges: MY large list of GAUGES for all reasons.

For those that like the best,

one can buy a fuel pressure sender and attach it to the above fitting and then wire the sender to the gauge in the cab.

If you have a 16V car , the pump pressure is hard to test with out special tools, having a permanent gauge is pure heaven. I'd get one.

I like the ones with senders at the pump and a passive electric gauge in the cab, never run gasoline lines INTO THE CAB , EVER.

Never mount a Permanent Bourdon tube gauge to any fuel rail on ANY ROAD CAR.

Never run fuel to the cab of any car, (not near people, ever)

Use a electronic sender mounted, as manufacture directs. Mount it , such that the plumbing is protected by the mass of the engine.

Do NOT project this device out towards the radiator and in to harms way , be that collision damaged or a simple belt failure.

Think before you act. It's a car , not some farm tractor. Never plumb fuel, into any cab for any car or vehicle.

Senders are here: At Dakota Digital.P/N SEN-10-2 - 0-75psi

Electric Ganges:

ProSport Gauge: $45 "MINE" I use this to drive and watch pressure under full load, it's electric and very safe to use, (its cheap like it's price but can save lots of hard work)

Stewart warner: $85

GlowShift: $40

Other brands, include Holley and VDO.

Keep in mind, this is more complexity and can be an issue in a collision. Keep it simple.

hydra locked

Always use fuel rated components.

Never plumb fuel of any kind into the cab.

Data collected: thread sizes on Banjo bolts into the Fuel filter,

mm = 12mm (into the filter actual) (Banjo size)

thread pitch= 1.25 or M12-1.25:

The Test port is 6mm thread. The Harbor Freight tool fits perfectly.

click

to zoom

click

to zoomMy TEST PORT connections using the Harbor Freight tool (comes with SUZUKI hose)

The MPI leak down and balance tests are much harder, and covered here.

DISCLAIMER: (De-pressurize,

first)

Fuel safety. see above

link that covers all that.

In all cases, see the

Factory FSM..

Rev 14 .