If there is no fuel pressure of at least 30 PSI the injector can not operate correctly. Same with blown fuses. (IG-COIL and "FI") same running an old packed up fuel filter. (20 years old is it?)

See tools here:

G16 engines:

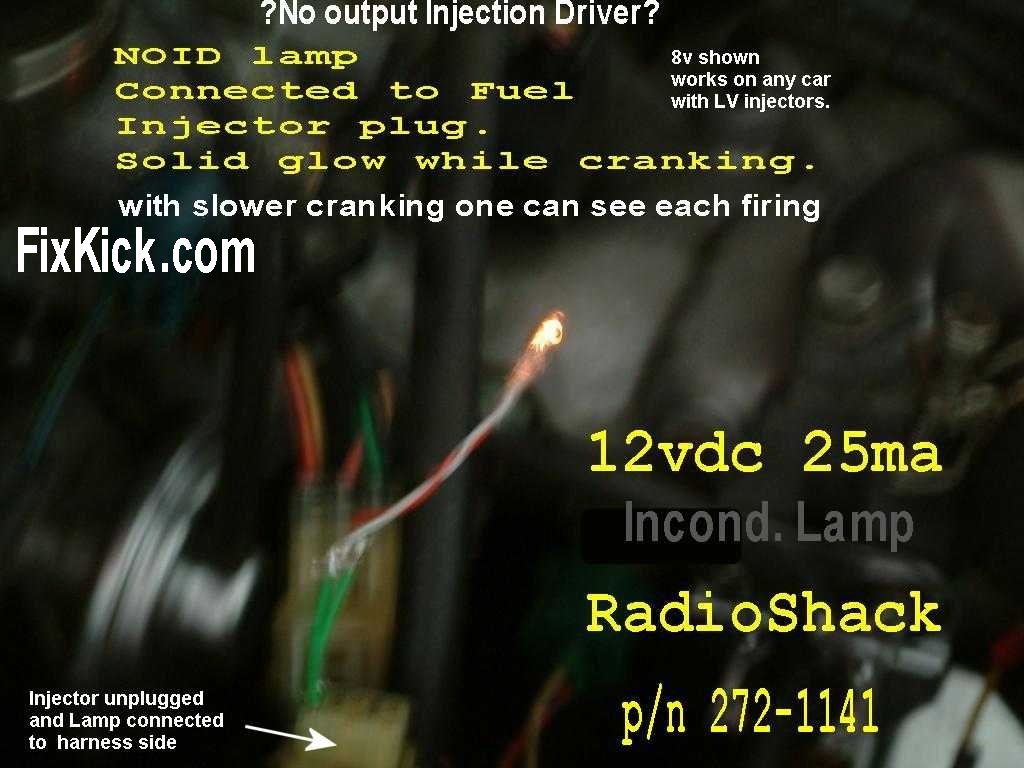

The NOID lamp is just a 12vdc low current incandescent lamp (not and LED) , or a kit sold for this on all cars, that fits the pins on the cars injector connector with out damaging them. (as seen below) (I made my own lamp using special back probing pins)

The Noid lamp excels at just 2 things, a Dead lamp cranking or running, or stuck on lamp keyon( not started or cranked)

But, there are lots of other ways to fail injection drive, besides just those 2 things, (weak drivers or leaking drivers are 2 more and both are impending doom of the driver.)

The ECU uses transistors to DRIVE the injector , the MPI uses 4 transistors for drive (grounds the injector fast) and the TBI uses 2 injectors that drive both pins to pulse the injector. (a ground driver and a 12vdc driver )

TBI drives ground and 12v both ! to the Injector (it uses a dual driver) (unlike say the METRO G10/G13)

There are 3 chapters here on this page TBI, MPI and advanced NOID testing of TBI.

Keep in mind that injectors can be heard to click with any stethoscope, but while cranking that might be very hard to hear, or impossible. For sure I can hear a good and dead injectors on a running engine, or with this tool.

It is best practice to check the coil resistance with any DMM meter set to ohms Rx20 scale, to be sure the coil is not burned open (reads infinity or over 20 ohms) (TBI is 1 ohms MPI is 10 Ohms ; make sure the MPI injectors all read the same !)

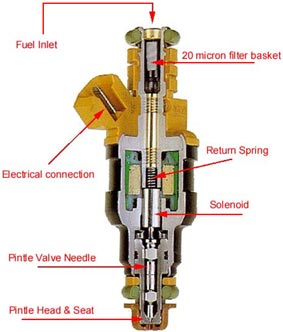

We are checking the coil (center)

drive signal to the 2 pins seen here. Note the very small filter basket

that can clog easy.

We are checking the coil (center)

drive signal to the 2 pins seen here. Note the very small filter basket

that can clog easy.The TBI injector has 2 wire pig tail leads, unlike this MPI injector above. MPI is 10 ohm coil and TBI is 1 ohm coil.

The injector must be pulsed or it will burn up. (never exceed about 80% duty cycle on the injectors) That means don't hot wire them. Hot wiring is 100% duty.

Never condemn the ECU before checking its inputs (CKP/CMP,TPS) and the injector wires and connections for rust. (if only 1 injector fails to pulse (electric pulse dead) that means the wire is bad or the ECU is bad (MPI)

TBI testing: The 8 valve G16A Single POINT injector engine is TBI or throttle body injected.

The many ways to do the NOID test on the TBI signal injector . I believe the word "Noid" is a contraction of Solenoid tests. For checking the drive signals to any Solenoid.

The purpose if this lamp is to see if the PCM (ECU) is really injecting on 1 or all cylinders, (it must on all cylinders and most not stick on)

The Noid signal can be (stuck on, flash bright or dim, if all flash bright good. if one is weak , then that PCM driver can be bad) If the injector lamp , is Stuck on keyon, that is a bad ECU or wiring shorts at the injector harness.

If all injectors fail the NOID lamp test. that means the PCM is cutting injection. (bad PCM inputs)

What is a NOID test lamp, it's just a small 12vdc test lamp (the best is a low current lamp to discover leaking injector driver transistors)

Some mechanics just use the "off the shelf (OTC) automotive test lamp ", many uses a 1 amp lamp and is not the best tool for the job, But but can find dead injectors and stuck on.

The problem with the test lamp probe?, is it damages injector plug socket test pins, and guess what Suzuki don't sell those plugs....... so.......

I use NOID lamps that fit car perfect. It is your car and your pins. (Most new car FSM books, have this warning message)

One way protect socket, is to use those tiny back probing probes up that connect to your test lamp.

WAYS ! (loaded or unloaded , loaded is connected..injector...)

Do not expect any NOID to be 100% accurate, only a SCOPE(DSO) does that, sorry!

Did you know the scope can see, partially shorted Injector coils? and see partially sticking injector PINTLE valves using any SCOPE?

But a Dead NOID don't lie. (that line is failing, for sure)

In the real world of electronics, things can go open (dead) short, or be weak.... that is a fact. the NOID lamp test falls down on weak drivers and on some leaking drivers..

Shorted injectors, open coils, partially shorted coils, shorted open or dead or leaking injector drivers in ECU or the wires bad to this injector.

- Back probing the LAMP directly across

the pins, of the

connector (not pulled!) Top way this is , a fully loaded test. Attach

the NOID

lamp to the

injector drive line.

The TBI single injector has a married, TPS sensor, in this connector. (so pulling the connector puts the PCM in to failsafe mode (a dead TPS) (limphome) this does not apply to the MPI system.(has its own TPS connector like the above photo)

- Pulling the TBI injector connector ,

puts the TPS TP pin to 0vdc (due to a 470k pull down resistor

inside

ECU (safety resistor this is) The ECU goes to limphome, the injector

still first , but engine may flood)

- My photos are all of

a 1991 TBI firing, with injector pulled, and the NOID inserted on the 2

injector pins, (using tiny back probe pin-plugs

as to not damage the

connector)

- You

can also attach the NOID directly to the ECU injector pins B8 and

B17 at ECU side plug(not pulled), using 2 back probing

pins.

- Do

not forget that a real scope out performs any test light on

earth, In

fact, you can see partial or full failure of the Pintle inside,with

a

scope.

I like way 1, above (no risk to ECU) Direct NOID connection on a live circuit, No connections pulled. (but the SCOPE is the best tool)

Is the Injector dead still? See my actual TBI scope readings (wide band scope here, very accurate)

Okay, you disconnected the Injector with the 6 pin TBI plug.

Check the Injector coil, it is about 1 OHM (TBI) , zero out the meter leads natural resistance, before trying to measure 1 ohm.

Cross the meters lead end together first, then,,

Subtract the crossed leads reading from the injector coil reading and that is the true coil resistance. (all this is in the DMM manual , I just paraphrase this...)

Some finer DMM meters have an auto zero button, cross leads, hit the button , zero happens, like magic. RTM (read dah manual) !

Cheaper meters...

EG: Crossed leads read 0.2 ohms. then coil reads 1.4 Ohms, subtract lead resistance and get 1.2ohms , a perfect injector coil. (just look for gross errors ( 0.0 ohm is shorted coil, 3 ohms ?is burned up, infinity is burned open coil)

Okay you made it here, with , no dribble, good fuel pressure and the NOID test passes, if needed (dead injections) and done and passes the NOID test.

If the NOID passes, jump to test 4 , pressure and leak down testing,

If the NOID fails dead, then the ECU is bad, or pin A1 is dead or the TPS TP pin is stuck high.

Predicates: ECU not throwing, 41/42, Tachometer shows 300 RPM cranking and TPS TP pin, not signaling W.O.T, (1v good, 4v bad) (or ECU cuts FUEL)

This test, finds most failures of all, It many not find a weak injector driver (only a scope finds the weak)

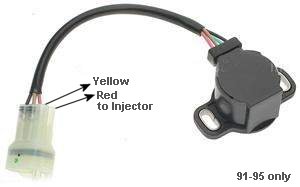

Pull this connector seen here. The other end of this connector is the harness side, and that connects to the ECU drivers. B8/B17 Red and Yellow.

In each test the NOID is connected to the harness side, after all, we are testing ECU drive signals. (the 89/90 has different connectors)

This is a real 91 to 95 TPS sensor with injector

pins. (89-90 slightly different here)

This is a real 91 to 95 TPS sensor with injector

pins. (89-90 slightly different here)8V TBI:

The injector drivers can fail in 6 ways (open (dead)/shorted/leaking ) Only a Scope finds all 3 x 2 ways, Red and Yellow.

See my advanced NOID test here. (this test finds most failures, unlike a simple connect once test)

The TBI injector has two drivers. One for hot drive and one for ground drive.

I saw one NOID light test pass, on an TBI engine, but the ECU had one dead driver. (shorted) The NOID lamp don't always tell the truth , unless it's a DEAD lamp.

Do not hot wire the TBI injector or the injector will burn up or you will burn up the remaining good injector driver, putting the ECU at more risk and damage.

This also causes, the Burning up traces inside the ECU is ,well, not too wise. and may make your ECU no longer, repairable.

Nothing beats a loaded injector test or better a real scope reading of both wires on the Injector !

The real thing , TBI scope tests

Actual 8v TBI Injector scope signals. Note the DIFFERENT WAVEFORMS!

Injector to ground driver(yellow lead)

Injector to HOT,(red lead /line/wire)

First is the $1 NOID. (or free !, gutted from any old dead car radio dial lamp) aka: a grain of wheat lamp, they seen in all old car radios.

LED? NOID?

And LED lamp may blink so fast, no human can see it. The pulse is 2 to 5/1000th of a second. Real fast! 3mS is typical, Any small old radio dial lamp can work great too.

This tool below works, if you can keep from wrecking socket pins.

The general problem with test lamps below is that many draw over 1amps current and many ECU outputs can only withstand 100ma (or 0.1 amps) using this lamp on ECU's is just ignorance from the 60's Old school mechanics. (pre EFI era)

The below tool is Infamous for damaging socket pins too. (but that don't stop many a mechanic from jabbing away, with no cares in the world)

A Store bought NOID kit, saves

the pins from damage it does. It's like

$20 cost.

A Store bought NOID kit, saves

the pins from damage it does. It's like

$20 cost. Any Scope works best, I can watch the injector live , running and cranking. (seen below with test wave form , here is our TBI real wave forms are here.) (the below is the first digital scope made, and mine still works!)

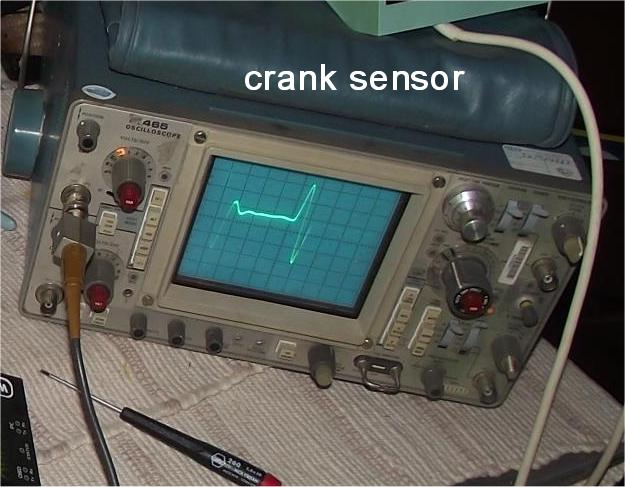

Here is my crank sensor. (if very weak on most cars and uses shielded cables to ECU so it can even see it) it's no more than 1v at idle. This photo is just to show that the SCOPE can in fact test the CKP sensor and NEVER LIES !

My point here,is a scope can see the true signal and all noise.

Some injectors drivers are bad and have NOISE on the line, ringing we call it. Or is a weak signal or the signal on the MPI line does not reach a full 0.0v due to impending injector transistor death. (seeing the true signal can allow you to see the Pintle inside sticking too.)

A noid lamp just finds 2 failures, DEAD and stuck on.

See the real TBI signals here?

end TBI.

MPI NOID testing: Multi point fuel injection the G16B engine. With 4 Injectors. (this section also works on all Suzuki MPI engines, J18/J20/H20/H25/H27 on up. (real Suzuki names for their engines)

THE NOID LAMP TESTS: A $1 tool (it's just a 12v lamp) or a kit as seen below.

The kit has proper fitting pins that prevent against connector damage.

We usually do this first, before pump pressure testing, do to its only 5minutes work to see if injector 1 is dead. (why take a fuel bath first?, use the NOID FIRST)

If the ECU thinks or is true? that there is no spark ?, doing the NOID test is a waste of time , the ECU never injects with no spark. Goto no spark.

More NOID lamp tests. (only using a SCOPE or DSO , will all failures be seen, No NOID lamp on earth is 100% accurate)

N.O.I.D? = My guess is short for injector solenoids ? (a NOID test lamp) It's just a light bulb 12vdc. (make one, buy one, or whatever, get a lamp)

Below is a store bought NOID kit. (Sold in all automotive parts stores in the USA)

Tests:

The NOID must not glow keyon (if it does, ECU is bad or this injector drive wire is shorted to ground. (bad wiring happens)

Key on, Stuck on, is a bad ECU. TBI but on a 16v just one wire can short to ground and glow the NOID key on.

The lamps below are all the same, only the fittings vary.

I unplug all injectors, (this prevents flooding) and test each cylinder injector plug 1 by 1, to see if stuck on (glow) keyon (not cranked ) and then I crank it to see if it flashes.

You crank over the engine with the NOID attached, and it must flash or seem to be on full time cranking. If engine cranks fast the lamp may seem to glow and not flash , this is normal (a scope look proves it really is flashing, for sure)

The ECU pulses the NOID quickly cranking and seems to stay glowing , its really flashing but your eyes are too slow to see that (and the element persistence....)

IF the NOID fails, say IT IS dead cranking?, that is because of one of the following reasons.

- Bad

wires from ECU to injector. (that means no opens or

shorts to ground.) good wires, good connectors and good

insulation.

- A shorted, injector coil. (do the NOID test , with injector

unplugged.) the TBI coil is 1ohm the 16v is 10 ohms , never zero ,

never

infinity.

- The

ECU bad . (never all 4 dead, just 1 possibly) Do not proceed

until all

4 are checked, or all 6 on a V6. If all are dead, see line 4 below.

- Inputs

the ECU are bad (TPS stuck wide open throttle (TPS-TP pin not near 1v

but near 4v wrong) The spark is dead. ECU cuts fuel for dead

spark or

CMP dead.

For checking injector ECU

signals This kit I have trouble seeing the light , it is weak.

For checking injector ECU

signals This kit I have trouble seeing the light , it is weak.Any single injector drive stuck on is a bad ECU or a shorted harness wire on this bad injector. If lamp is dead, he wire can be cut or connectors rusty to this pin.

Bad wiring? see this link.

The NOID can be connected with or with out the injector plugged in. (I call this loaded or unloaded testing as any good tech knows, that loaded drivers can fail as can bad rusty connections.

I recommend doing both ways for full information, (eg: flashes with no injector, but does not flash with injector connected, shows a weak ECU or bad wiring)

To do loaded testing I have a set of back probing probes. that allow me to back probe connect my NOID.

The ECU reasons for failure to inject. (electric only, not a dead pump. )

- You Lost 12vdc power (FUSE BLOWN?) or ground, to the ECU. (if the CEL lamp glows, key on, the ECU has power but there are 3 fuses, the dome is memory fuse and will not cut fuel, only FI and IGcoil fuses need to be checked)

- The TPS TP PIN3 , signaling wide open throttle at all times, this kills all injections while cranking. A.k.a: Super Secret Unflood cranking mode. or W.O.T un-flood.

- The spark feed back 16v pin A8 ( the missing suppressor module cases this , if spark is good.) The Tachometer is dead. is it?

- The dash tachometer uses, the A8 Ignitor signal to work, if the Ignitor is dead, if dead so will be the Dash tachoemeter and all spark is cut by the ECU then Injections are cut next (in and instant), on purpose to stop fires.

- CMP

dead. (cam sensor , in distributor SOHC or on left rear cam end,

on DOHC engines) If pin A8 is dead, or CMP dead the ECU reports

this, if you scan and look. (code 41/42, P03xx errors or DTCs)

- A bad ECU, assume this last,

In the USA Cardone sells

the best refurbished ECU. bar none. They test all functions , unlike

many online auction hawkers.

Advanced TBI NOID testing: (in the effort to see most of the possible failures for $1) This is G16A technology 1989-95. (USA)

The 1 test way?, using a scope , if the modulation pulses seen here are missing?, one of your drivers are shorted in the ECU.(yes ECU is bad and engine fueling is horrid)

This is because there are 2 drivers in the TBI ECU ,engines. "yes, tricky" (unlike say, Metro/Swift TBI that works like MPI the metro also runs a series 2.5 ohm injector resistor... for those folks landing here with Google for that...)

Connect the NOID to the harness connector . per the below instructions.

The ADVANCED NOID TEST (TBI injector DRIVE, is harder to test and shown below) One can do 7 tests here depending on the success of each test.

Only a DSO "scope" does this with 100% success. (there are 8 possible failures of open /shorts/weak or leakages , 4 fails x 2 drivers)

The lamp test is very poor at finding weak drivers. ... or weak leakages, the sure sign of impending doom. (for sure)

My NOID uses small currents. this finds leaking drivers much better than the high current type. Use my 0.025 ampere lamp for best effect ! I gut and old radio for a dial lamp, this works great.

Some automotive test lamps use low power lamps , those that use 1 ampere lamps don't work too well for leaking transistors in ECU.

Do not use only a DMM (for tests) as your only load, it will FAIL, only a 1 ohm Injector , or a NOID is a proper load.

For the same reasons, do not use an LED as a NOID, or the leakage in the ECU (normal) will show odd indications. Use a low power tungsten lamp.

These set of tests, make the NOID test far more likely, to find a bad driver, in the TBI ECU, (it is tricky, with 2 drivers!!!)

The 3 tests are, across RED and Yellow, then Red to ground via lamp, then yellow to Battery plus, via lamp.

At no time, do I ever connect the battery to the harness wires directly. The yellow test must be done with care.

warning , 1 ohm injector (this one) may be seen to read 0 ohms, use a better meter... one that can't do low ohms accurately and do the zero calibration method seen it its manual.

This 2 pin incandescent NOID has no polarity, it's just at Edison, tungsten lamp. (the TBI injector is a tad tricky, due to its 2 driver methods)

In brief:

- The cars injector reads near 1 ohm (TBI) if this

reads

0 ohms or infinity or even 10 ohms its a bad TBI injector. IF fail,

stop, get new injector.

- Transverse test{aka; ACROSS "classic way"} leak test(NOID replaces the injector) a loaded NOID test, lamp does not glow key on, (not cranking, not running...)

- Same as above but the NOID must glow cranking (fast

flashing seems solid cranking). That ends the Classic test, this only finds

1/2 the failures times 2 wires.

- NOID pin1 at High side B8 (red)

and NOID pin2 to ground using just a NOID. expect No glow,

just key on, (if

it glows now, the ECU is bad, leaking driver is the cause)

- Same as 4 but, you cranking , lamp flashes or seems

to glow , cranking,

(if not, the driver is dead !) the fast the

starter, the more it seems to just glow, and not flash.(normal)

- Yellow test, connect pin 1 of NOID , to B17 yellow

pin, then connect (carefully) pin2 of

NOID, to the battery plus lug.

keyon, no glow! do not let

battery lead touch yellow.

- Same test setup as 6, crank, the lamp flashes, or glows. good driver. low side

A leaking/shorted driver fails, step 2 or 6 (if the lamp glows just keyon, the driver is bad, that is, it is shorted, or leaking badly) BAD ! ECU !

Or harness wires shorting to the body, etc.

An open driver fails step 3 or 7 ( no flash or glowing, means a dead ECU driver)

The leak test is, keyon, no crank, no glow. (not running !) Glowing here is leaking bad ECU driver, unplug ECU, still glow? yes, harness shorts.

Keep in mind if one driver shorts? , it can seem like the ECU is good, and is not. steps 4 to 7 find the truth. (most times)

That is why the traditional (2 pin, lamp across, single test) NIOD test, is so inaccurate on TBI engines. (not dead , not stuck on)

The details: (long wind)

I offer this final test, for those that don't want to spend $400 on a rebuilt ECU, or $1700 at Suzuki actual (new)

For those folks that want to do advanced NOID tests, on the TBI. (the TBI has 2 drivers) SEE THEM on my rev. engineer. page.

The first test is already done above, Injector coil ohms is good (near 1ohm), if not injector is bad. stop ! buy new injector if open.

The sad truth, is the NOID test above can PASS and it's still bad, how is that?, (why?, the answer is, a shorted ECU driver!)

The failing NOID (called the transverse injector test) "across the 2 pins" ( if this fails, the ECU can still be good, with dead NOID. (TPS TP stuck at 4v, no spark, no tacho)

Hint1: Shorted wires blow up ECU drivers for the injector..... (shorted harness wires or open wires, will cause the injector to fail or shorts blow up the ECU )

The below finds the truth. I will check the ECU side and Injector side and if the ECU seems to be working (signs)

You can at any time unplug the ECU, to see if it is shorting the Injector drive wires, yellow or red.

The tests repeated 3 times are, Transverse test , hot to ground and low driver to power , tests.

The Transverse test is 1st. after that, even passing this test we proceed to the next test.

RED DRIVE:

The injector main hot wire, Red must pulse the lamp with the lamp connected to it and engine ground. The Hot side driver test.

I connect the NOID up, its 2 pins , one pin to RED connector at harness, and the other NOID pin to engine ground. See connector in above photo.

I do 2 tests , here, expect no glow key on ?, and must flash or glow cranking, car will not start because the injector is unplugged.

NO glow key on

Yes, glow or flashes cranking.

YELLOW DRIVE:

The low side driver wire, yellow, must pulse with the lamp connected to it and the +12vdc battery pin.

Again the NOID has 2 pins , i connect just pin 1 to the Yellow connector pin, then the other NOID pin 2, (not 1) to the battery plus lug (12vdc)

No glow key on.

yes, glow or flashes , cranking.

Yellow option 2 test: (I like this way) Using a powered lamp.

Much better is to use a new tool a powered lamp, the kind with tiny AAA batteries inside, much safer for the ECU. B17 to ground lamp + to B17 !

Test lamp ground lead to engine metal.

Test lamp tip to YELLOW pin.

Key on the lamp don't glow, or the ECU or wires are shorted.

Last, we crank the motor and the lamp flashes. A good ECU driver.

If the NOID glows just key on , for any tests above (all 3 tests) the ECU is BAD (or harness wires shorted or cut)

Both drivers must switch "pulse" running, or fueling will never be accurate. (very unique to any TBI )

You can repeat the transverse test on the ECU connectors, B8 to B17.

if dead, the ECU is bad, but what if you saw a faint flicker here,

What if the ECU was disconnected the NOID lamp glows, keyon.? Bad harness.,

I'd first check for continuity in the 2 wires and for shorts in both, with any resistance ohm meter. end to end and shorts to body.

last in a panic, I find a short in the harness, but cant find it with vast inspections.

I then.....

Cut the 2 wires to this ECU pins B8 and B17 and test 1 more time at the actual direct local ECU B8/17 pins, does the lamp flash cranking now? GOOD ECU.

You might do the other 2 tests, on each pin to see of both drivers are off key on, and BOTH flash cranking, that is the sign of a good ECU (injection focused)

Some just cut the wires and wire in new injector wires, when they find harness shorts here.

The ECU can be bad with 1 shorted driver, and the car will run rich forever and pass the transverse (across INJECTOR pins) test.

Car starts now... ?

(if not? the injector is clogged, have it serviced ( NOID passes, and fuel pressure is 30PSI (ECU is good so.....) bad A INJECTOR FOUND.!

See how the drivers really work here.

Why any LED lamp may fail to blink but the incandescent does?

The injector electric pulse is faster than they eye can see. (Human biology)

This is why the NOID lamp works and an LED like this may not work.

The facts of why humans may not see fast pulses of light:

If say the light flashes for 5/1000th (5mS) of a second every second, you can not see this flash.

The human eye needs about 90 photons to perceive light, (60% of folks can't at 90)

The human eye needs (roughly) 50mS at the retina, and then 100mS for the brain to integrate this data. And 300 to 500 mS for attentive (the brain) awareness, Ah, I see it. (a pulse of light)

Varies human to human and other factors, night or day, and the hit rate ,the pulse repetition rate)

If the hit rate is fast enough we see it as a steady light, (like in the movies, 20 frames a second) My TBI engine while cranking the lamp seems to glow steady.(but if the car battery weakens and starter slows, it starts to flash (gang fired they are,cranked , MPI)

The incandescent lamp "Noid" does that magic, it stretches the energy to heat and light inside the filament.

So humans can see it the flashing but Varies human to human and other factors, night day, etc. (the so called night vision allows us to see dimmer light)

How ever many folks can hear a 5mS beep.

We can hear the injector click is one example. (using any stethoscope)

The noid lamp can be made up from many cheap lamps DIY. (up to 5 ways to test as seen below)

Back probing tools: (based on the theory "first do no harm")

The NOID can be connected using the Back probing needle method.

Or buy some probes here.

This probes fit standard banana jacked test leads. (I have 2 of these , 2 banana jacks to wires and the 2 wires to my noid lamp.) These tiny pins will not damage injector female socket pins.

back probing tools. (tiny pins)

back probing tools. (tiny pins)There are many tools that work for Injector DRIVE signals (each but the , scope has CONS):

Any scope. ( best of best)

A noid lights.(seen above)

A sonic tester (a tool tuned to the sonic frequency of the moving Pintle)

A Stethoscope (sonic too at $2- 5 cost at harbor Fright)

Injector body , the old screw driver from injector body to human ear canal, some can hear the clicks, I can't, too deaf. (Viet nam bs)

For injector flow testing (balance) I use an Injector pulser (mines just $12 Arm processor, I programmed and made my own driver) but here is a nicer tool , one at a store.

version 19 ++++ 4-1-2015 (exported v18 out of injector pages and cleaned up a bit.) (org. from 2007 pages) My page here, now focus's hard on INJECTOR DRIVE signals. (all ways possible on one page)