The Wiki on Interference engines.

What does interfreance mean, well that depends on who's asking ( race enging builder or "Sally twinkle toes")

All engines are intefereance if you "suck a valve",( means the keepers fell off, or spring broke , stems snapped or the poppet head blew off) ALL.

All or most engines will be interference if you manage to hit 10,000 RPM and you FLOAT the valves (like me ,with my custom ECU, but never SALLY)

For the man in the street, it means the stock engine & stock cam (some countries have different cams, "fact") may crash the valves, if the cam drive fails.

Crash, as in pistons hit the valves. (the valves bend and can compound to total engine destruction at max RPM)

In some cases the cam bias saves you, the cam halts, at a point that is lucky , is this confusing this BIAS?

To learn this , drop your belt or chain, set the crank on a G16 (1 example I-4 ) to TDC +90 degrees, this puts all pistons at 1/2 way point.

Now spin the cam cog by hand, feel that bias?. Now in your mind imagine, the cam turning say 3000 RPM and then the belt snaps.?

Where will the valve lobes land?, Who knows , but BIAS can win. (save you or not). for sure the lobes will land on a BIAS point, after that, who knows?(nobody)

Bias is the total action off all springs at the same time.

The cam bumps alone, hand turned, feel that bumping? BINGO for BIAS. (each point is bias point, learn this next belt change , play with the cam)

Now you know why some interference engines don't crash, it's called PURE RAW LUCK. (luck is that NO valves are not open 100%) pure luck.

Now you know why useless consensus posts are wrong, (lacks enough example data and lacks Forensic data)

What if the head and deck were milled? and then you set lash wrong on one valve, sure it can bend. Even on a free-running engine.

Bob asks why is it designed to be inteference, answer:, To make more power !

See this video, the left side is Exhaust , see the piston chase it closed. Bingo this situation?

In this video, note how to valve does encroach into the pistons swept area? No?,watch it again.

In engineering terms, it means the pistons can kiss (smash) the valve poppets with the piston, under any conditions of cam drive failure.

Some SOHC engines with stock cam(s) have 0.040" clearance at any times running. (normal,valve to piston, at all times) (NOT MILLED HEADS)

These engines are also called free running. (obvious ,right?)

You can set the crank at TDC 0 degree's , remove the cam drive and spin the cam over willy nilly , no hitting. (by hand gently) Sparks out.

Ah, no hitting sure. I now understand.

So, what can cause this RULE to fail? (usually just service errors, and not doing the machinist checks, bad as that is...)

You add them up and that is "stacking errors". The chips fall where they lay, "reality, is a beach"

Like I said, it's 20 years old, so.....

- The overheated

engine + (pistons /rods expand hot "Thermodynamics" )

- Then at 6000 RPM.+ ("at higher RPM's the pistons move higher "

- and wrong head gasket?( too thin)+ oops?

- Valve lash set

wrong (set willy nilly and way too tight. READ the FSM ONE MORE TIME?)+

- Normal engine wear. (see rod clearance max. in FSM?)+

- Wrong pistons in engine (it's 20 years old ,who knows what is there?)+

- Running a milled head are you?+ (Shaved, cut after it warped?)

- Wrong cam or a cam from JAPAN JDM real? our

book shows 4 cams, in the parts list world wide, and there are

aftermaket cams. SUZUKI is silent on spec !

- Ask your machinist what are stacking errors. BINGO! they can add up! He checks this every build !!!!

The factory books state the maximum head milling rules, this milling also cuts in to the .040" clearance. (this number is a good guess, Suzuki is SILENT)

The word inerference INCLUDES "NORMAL SERVICE LIFE" of the engine and that means head milling too.

The block deck can be milled too, in the normal service life of any engine.

What your engine does dead cold only , means nothing to the engineer, he wants your engine to stay alive , even when old , cold and hot. (and when overheated too.)

This includes the Air fuel mixtures wrong , causing heat build up on parts or even Pinging, (we don't have knock sensors on G16's so....!)

Even in very hot engines stuck in ECU failsafe mode.

The 16 valve engine has valve piston notches, and are not there for squats and grins, it's there because, the pistons chase the exhaust valves, very closely, as it closes. Fact !

We do not have the official Suzuki spec, on the dynamic valve to piston clearance worst case, Suzuki is silent and I forgot to measure mine after putting in a new crank. (dang me)

That is right, some countries have more lax smog rules, so the cam in that country is tuned for more power. Fact !

What to do?

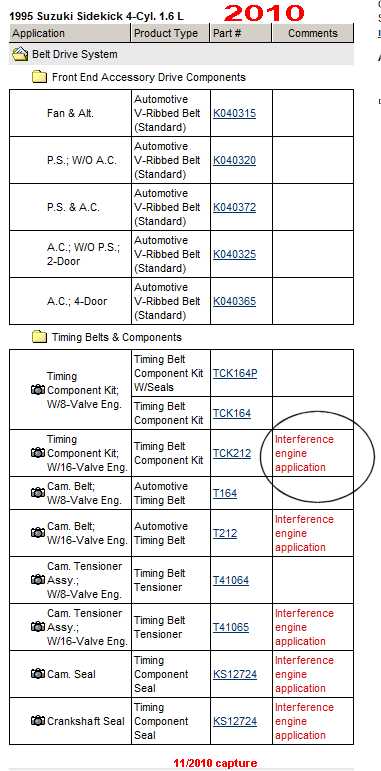

Here is a list 1 of interference engines.

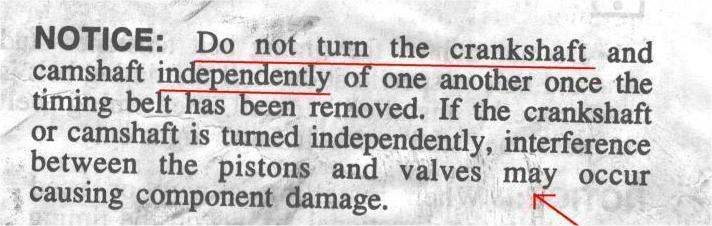

This is a real snap shot of the SUZUKI FSM page 16V only, and repeats over and over. It's a world wide warning!

I think the word "may" means, on all engines sold in the world G16B, ALL. Some for sure are free running by any standards. USA engines. All mine are.

One more list of Interference G16 engines. (my guess is they read the FSM and copied the words there)

All Gates belts catalogs "USA", warn you like the below.

As does all other belt makers.

I'm very sure that GATES only repeats the above FSM warning, they sure didnt check it them selves, I'M SURE.

WHAT TO DO?

Stop reading rumor and blogs that do not even say the country they are in, or what engine they have..

(First off, I don't believe any of them , I'm a skeptic, I believe my eyes and my tests) All good mechanics (and technicians) are 100% Skeptics. (by nature and need)

Rule 1: I assume all DOHC engines are interference, more than half are, may be more..

Then I treat all SOHC engines, like DOHC, becauses some are inteference, but not most.

Test one, at belt change out time: G16 ) a non HLA engine, solid lifter engines.

I have no belt. now , it's off

I put the crank to TDC (marks) (spark plugs removed)

I then hand turn the cam cog , and turn it 360 degree's (1 full turn) (feel those normal thumps)

Did it hit? and lockup, yes ?,then its and interference engine or you sucked a valve or the valve lash is WAY WRONG. (or some other head damage, springs broken , bent valves?)

HEAD OFF:? (we do this on all milled heads or block)

Next time the heads off? (all motor builders books and race engine building books, cover these steps) (or use the weak valve spring kit and a dial indicator to measure this gap, far better)

First off, many of these engines, are 20+ years old. So, why would you expect it to be still in stock condition, luck, hope, or ? Nah, what you do is Inspect it.

Every engine builders book in print, has these steps (it's not something new, or invented yesteday) (I have most those books, on my shelf )

LASH SET TO SPEC, The head can be lash set on the work bench (SHOCKED?) (The cam is fixed inside the head is why)

- Put clay in the 16v piston fly cut pockets. (about 0.1"

thick) (if paranoid , like me, do all 16 pockets)

- Put the head back with the old gasket, and torque it. (if

flush with cash , waste a new gasket? (starting with 2 new gaskets, the

latter , on final assembly)

- Now, put the crank at TDC. (the 2 marks aligned at 0 degrees )

- Spin the cam 360 degree's , by hand.

- Put the crank to TDC + 180 Degree's. (1/2 turn) (this G16 engine fires every 180 sure)

- Spin the cam again. 360. (full turn)

- Pull the head.

- Measure the clay crush depth, I pull the clays and cut them in

half and measure the squish. Below .020 is very bad, and on race

motors it's 0.040" goal. more for wilder engines, NOS, or boosted.

- If bad, ,find the cause and correct it now. (pistons right, deck height?,

There is a weak spring (valve ) kit sold , we put a piston to TDC firing.

Then turn the cam until the lobe is at max (repeats for all lobes)

Then using a dial indector on the valve spring top. we push the valve in to head, and read the clearance measured now. This is free play valve to pistion, that SUZUKI never specs.

Better is to just push hard on a stock spring.

Only serious pro engine machine shops do this. (savvy they are)

What I try not to do , is make the engine worse by my actions. On some engines, that is very easy to do. 1st. DO NO HARM.

( check cam timing first and leak down rates by HAND, if a real skeptic, as all good technicians are!)

Check for interrence after the cam drive is installed.

Then if OK , do a cylinder leak down test next at TDC firing x4 . if below 15% ok , if the valves leak like mad? (hear that in the intake or exhuast ports?) then the valves are bent.

Most old cars are rife with errors. (wrong parts, dead parts, or set wrong,etc) I assume this.