16 valve 1.6 Liter, Sidekick Timing belt swap:

USA engines 1992 to 2000' The USA Vitara dropped G16b in 2001.

The below applies to factory stock (OE spec) motors and cams, only in (N. America)

The Valve cover can STAY ON ! (but is not advised) It's good to look at cam action, and a new Valve cover gasket , no is a good thing.

The crank cog/bolt can Stay on, but is but is always (1st time) to look use the new TSB for Torque.

The GM book has gross errors. see that here.

The torque settings are here. do not use GM settings, see errata at the end.( See 6mm warnings and non ISO Suzuki pulley bolts)

I write this page not knowing why you are here (normal 60k belt swap) or the engine died?

THE ACID test and the sneak-a-peek checks.

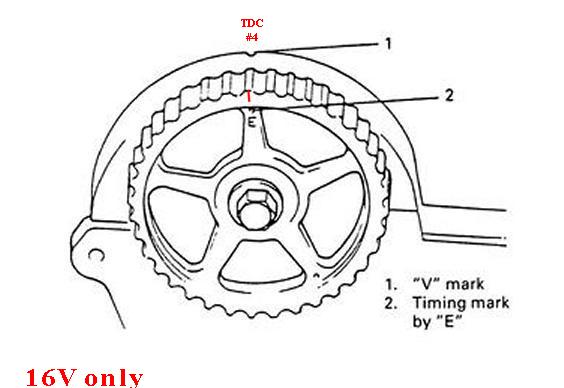

NEVER TIME the CAM at TDC # 1 cylinder firing ( forget that IDEA?)

This cam is timed at #4 firing ! NOT #1 ! READ THE real FSM carefully or mine below)

Ouch,

click to zoom, that is damaged by loose belt.

Ouch,

click to zoom, that is damaged by loose belt.My Opinion:

Most non OEM published procedures are flawed, they assume too many things, like the belt is not slipped or the distributor was timed correctly. Motor good., etc.

Most generic store bought manuals get many facts wrong. I call them Rags, as that is all they are good for, is to mop up spills. (they have great warnings and safety! topics)

Most books assume there are no failures.

Many store bought manuals (Rags) do not even consider, you have a new cam, new head/block or head gasket. (HOW CAN THIS BE ?)

Nor do they consider , bad maintenance or bad motor, or other failures.

Some use the Distributor as a reference point to setting the cam, This can cause great troubles. Don't look at the Distributor , leave that for LAST.

FSM = Factory Service Manual. (only GM and Suzuki publish these) {ebay has them used, dirt cheap ,get one for about $28 used}

Replace the Timing belt , Idler and water pump. (at least)

Some like to change the seals ( I don't if , it don't leak)

Changing the crank seal ,USE electricians tape on the shaft to protect the new seal , you will fail if you don't do that.

Buy the full GATES kit with idler. Rockauto.com has this kit. It is very high quality. Do not mix up 8v and 16v belts, look carefully here. The TCK-212 fits the 16v engine.

The Gates kit DISCOUNT$ the idler !

The idler by itself is very expensive.

The actual FSM 4 pages with annotations by me.

The FULL 96 FSM is also here. See chapter 6A

Jargon :A/T is Automatic transmission, P/S is power steering, A/C is Air Conditioning, CCW is counter clock wise.

Phase I:

- Pull battery Minus cable and hide the IGNITION keys. 1st !

- Remove all spark plugs. (first, blow out the spark wells and check dirt, get the wells clean ) oil here is a bad Valve gasket set .

- Drain Radiator at bottom left (drivers perspective) tank.

(take off the RAD Cap to help , after full cooling of motor)

- Remove the fan stud nuts and then remove shroud and

fan at 1 assembly.

- Consider removing radiator (harder on A/T cars or A/C opted cars) . On Automatic, radiator can just be left installed, but slows the job.

- It may be possible to tilt the radiator by loosening all mounts, associated with

it, to do service , but I remove the RAD every time.

- Loosen the 3 Alternator bolts/nuts, and swing it inward. (use a spanner on the lower inboard rear bolt/nut)

- blank

- Remove Alternator V-belt/ Serpentine belt . (an any

other belts, that

block the front T-belt cover) P/S , A/C?

- P/S has a hidden bolt , bottom / front , dead center, through the pulley , use a socket wrench, loosen all bolts and tilt it, inward. < Skip if A/C car.

- IF A/C opted car, the belt tensioner was moved to the A/C mount, so. loosen the A/C compressor. And remove its belt.

- Remove Crank Damper pulley outer ring screws ( by

unscrewing

the tiny 8mm

hex headed bolts around rim) Allen heads are none

stock, if found.

- Remove the T-Belt cover. Bingo, behold a timing belt, look for and correct damage, I check timing marks ,and see if the cam timing is off, and make note of that.

- Attempt to get the "E" Mark on the cam cog to 12pm, and crank to TDC NOW!. if the valves hit , try moving both gently CW or CCW to get timed..

- Loosen the 17mm

hex bottom cog bolt (CCW) using a deep wall socket wrench, OR a

huge breaker bar. (feel it turn CCW, was it loose?) ( fly

wheel locks or 5speed in 5th gear here, helps)

- Go to Phase II: Step 15 is optional if suspicious of the key inside. More later on this below...

Some engines have allen head bolts here, and are way more easy to find than any Queer, 8mm headed, 6mm bolt.... vastly so.... I'd use them if , the origionals are lost , or damaged or wrong.

Suzuki sells those screws but takes like 14 days to get them , I'd not bother.

PHASE II. (If replacing crank seal do #4 )

- Loosen & remove the timing belt IDLER center tensioner bolt. and associated parts.

- Loosen the spring stud bolt. (test this device idler plate, for being free to move and no binding after loosening it.)

- Wiggle all parts there, till loose and take off belt and

spring. ( as necessary).

- Optional Remove the center 17mm large crank COG

bolt and wheel and inspect the key way ! This is optional, and 1st time I do this. The tool I made, is here.

- If the key

way is damaged , you need to stop now and

seek expert help. You have a

serious problem.

- To REMOVE the large 17mm bolt , requires, 5th gear (if 5sp) or a flywheel lock or a front cog locking bar (the latter is easy to make see notes below)

- Correct any crank shaft tip damage and put on a new cog and bolt and set the bolt to 94-Ft/lbs and use loctite on the dry threads

- blank (end optional steps.)

- Align the CAM cog "E "mark to 12pm on the top back pan, and the crank cog to TDC marks (12pm) (see the great photos below for this alignment)

- Put the new belt back on , with the right side (drivers left) of the belt tight , no slack, all slack must be on the opposite idle pulley side.

- Warning, the

new idler

wheel must be indexed (tab on inside edge) to the idler ARM, so they

INDEX and track TOGETHER smoothly ( or all bets off) Nor Damaged.

- Put back the spring / idler and let the spring take up all slack. now just set the 2 bolts finger tight, then back off a tad, so spring device barely floats.

- Make sure the spring plate TANG indexes

properly behind the

idler bushing (back side index ) so that spring powers the spring

plate. (look careful see warning 13

below )

- Check the timing again, with no

slack on

the right ( left side, for the drivers perspective) Stud nut and idle bolt 1/2 turn loose.

- If all checks out , rotate the crankshaft 2

Revolutions CW( Clock-Wise facing rear, at crank big bolt 17mm) , spark

plugs removed helps GREATLY ! (valve lash normal)

- The spark plugs are removed , see tiny tension

spring device , set the exact

tension on the belt !by the 2 turns CW ! the tiny spring DOES ALL

THAT. "yes hard to belive.."

- This extra steps allow the tiny little T BELT spring , to

take

out

the belt slack. Once set perfect, we lock it down. (that stud) and the spring does NOTHING for 60k more miles.

- If the timing marks are again perfect , like in step 9 above, then now lock the Idler tensioner bolt and the spring stud to spec.

- The engine cam is now timed PERFECTLY and tensioned right.. Make sure Idler stud is set to factory torque.

- (I do a validate compression

test on #1 only , this proves I didnt mess up or some set lash wrong ,etc and the ACID test here (key

ways x2 and marks)

- I then check that the crank is at TDC and in fact the

piston is at TDC using my TDC finder page as a

guide. (or eye ball the spark hole)

- Reverse the above procedures , (access gained on previous

page)

- LAST time the Distributor. using the 16V section

Warning 13 ?: In step 13 above. the idler base plate has a tang, this tang must be indexed to the idler base (backside) do not guess, index it, or you will have 2 failures, one it that the tension step is never going to work (loose belt) and now the idler is canted, causing belt drifting and hitting cover, a DOUBLE FAIL!

The below new photo makes this very clear. See that TANG, about to fit in TANG hole, This is a MUST DO. "Thank you, COSMIC"

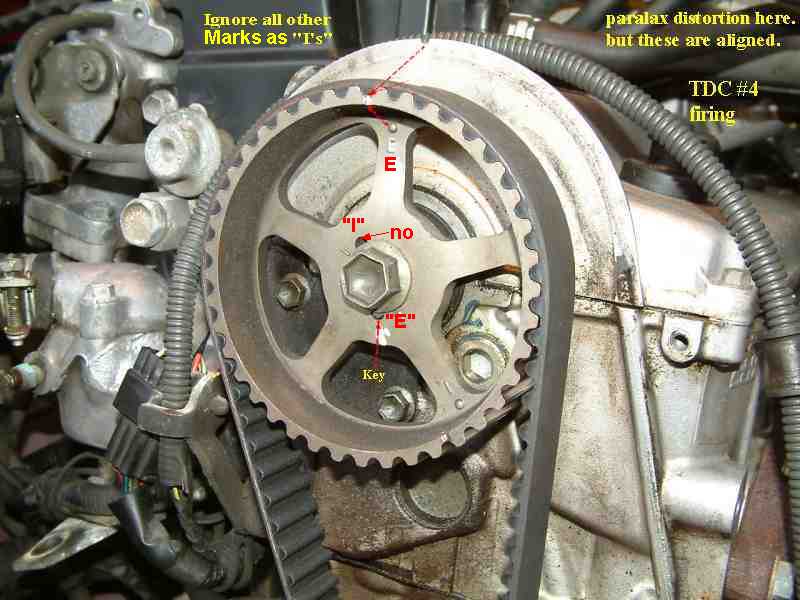

Drawing #1 16v Cam Cog gear: Click below to zoom and see real photo.

< Click to zoom

< Click to zoomPhoto 1: Crank cog gear:

click to zoom

click to zoomNote the crank key is at 12PM !!! see it , check CAREFULLY THIS !!!

See that Mark above crank cog , cast into aluminum oil pump housing. See white mark above cog.?

See that Mark on crank cog itself., see my white mark here.

Proper tension is critical, it happens by allowing the spring on the idler to press on belt with the pulley.

The key here is all tension comes from that tiny spring. (on the facing belt left side). Never tension a timing belt like an accessory Serpentine belt.

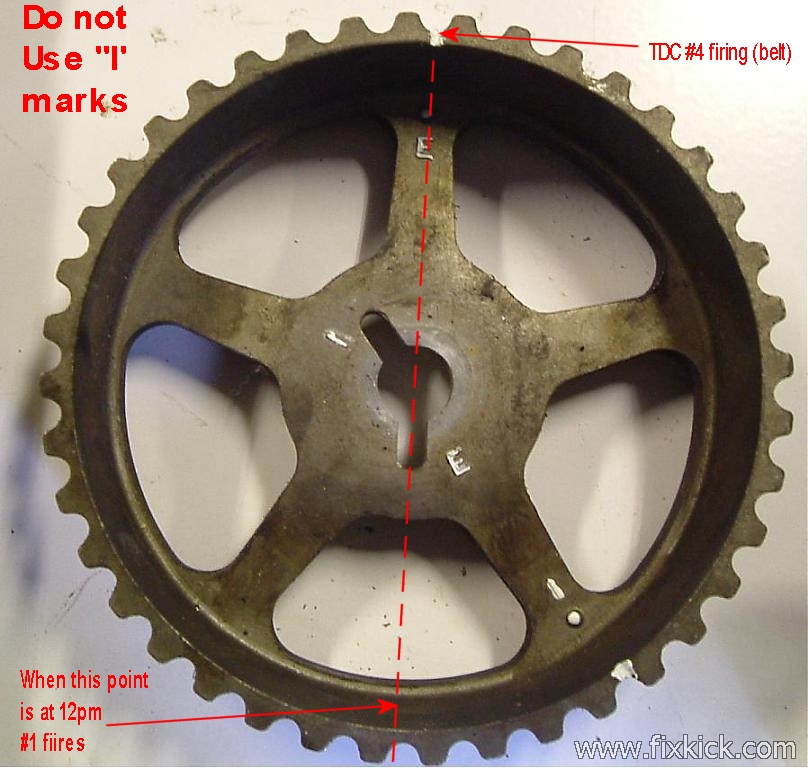

If you decided to remove the cam cog wheel , you will see that "the key way is at 6pm, "E" the "I" key slow it WRONG !

This Cam wheel MUST be set correctly , do not proceed until it is correct.

There are false marks do no use any false marks.

Keep in mind that spring only works before the lock down , setting the exact tension, the spring is now useless until the next 60k swap.

Note1: the 17mm bolt must be torqued to 94 lbs/ft ,and this can be done, 4 ways.

1: 5th gear , rear wheels chocked in 4wd High. Manual Tranny. Works perfect for me. with 5 speed.

2: AT- 3sp/4sp, with bottom flywheel pan removed and using a flywheel lock (make one. buy one) Suzuki sells them. HUGE VISE GRIPS work perfect.

3: Chilton's says, wrap damper pulley (its back on now) with duct tape and use a chain wrench to hold the pulley (an ugly procedure, gross way.)

4: My way is pulley off, and home made crank bottom cog lock , made of angle iron and attached to , ALT/AC or PS brackets. Drill holes in tool.

Note2:

Please do not rip your cam out or pop off the belt , just because the Distributor is mis timed. Please don't.

Set the cam, then set the Distributor , there is no OTHER WAY. ( and surely never time Distributor and then time cam, as some store rags say to do)

Please use these steps, as an adjunct to the above linked manuals FSM factory documents.

There maybe?, other ways to time an engine, but this page is the FSM way. Feel free to try those other ways.

OEM SUZUKI SPEC. WAY!

Special Photos:

A photo of the 16v cam end with false key way and a marks showing which is wrong.

No manual mentions this fact, that there are 2 slots, ONE IS for G16B and the other is for a SF-413 DOHC motor.

ONLY USE "E" slots and marks. IGNORE ALL "I" MARKS !!!

Photo 2: The Cam belt is timed at #4 firing ! Just as the Gates belt instructions clearly state, and FSM. The "E" mark is at 12pm with the crank at TDC.

click

to see on cam photo.

click

to see on cam photo.Cam shaft key dowel pin down. E mark UP is the rule G16B, for setting the tension correctly. Ignore all "I" marks.

SEE the 2 false marks?, This same exact cog is used on the G13B and K swift engine, that is a 4 cylinder, twin cam engine, (on the G13 the E means exhaust side, and I mean intake side)

The Suzuki Swift 1.3L DOHC the real Suzuki name for the Swift is SF413 ! regardless of the other 10 names used world wide. (badge names)

DO NOT EVER USE either of the "I" MARKS on this G16B 16valve 1.6L SOHC motor.

Tools and materials: ( outside of full socket sets metric and deep and shallow and metric spanners)

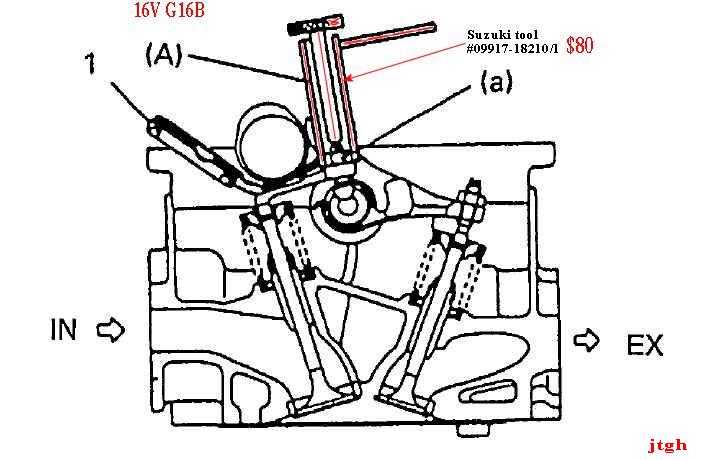

The only special tool needed is:

A feeler gauge

and a crank shaft locker if car is A/T.

MY lash procedure: (always LAST)

The below tool is not needed , it is only an option.

Drawing 2:

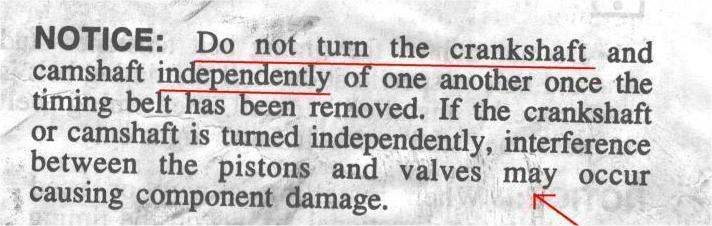

This warning shows up at GATE Rubber here

The below is in all USA Geo and Suzuki G16B books published for this car. YOU DECIDE WHAT IT MEANS ! (I think it only applies other Suzuki engines! NOT MINE )

There are like 4 to 5 cams used on all G16 engines, world wide, I can comment on all engines.

If the head is milled, vastly bad can happen if the belt snaps. (or that and lash set tight wrongly) pays to be careful and set all cam belts exactly to spec, and for sure all DOHC engines. 99%

The Below photo is not for timing CAM. !!! This is for parts identifications ONLY.

Drawing 3:

1996 GEO TRACKED, 16V. Properly TIMED ! Look carefully, all secrets are shown here, all 6 Points of Reference !!! 3 photos. This is really all you need, for timing.

Photo 3: (see the ACID test here)

Click

to zoom

Click

to zoomAbove, CAM KEY DOWN, "E' MARK UP. Really, can it be more clear ? the above?

Photo 4: (ignore the TONE wheel in years less than 1996)

Photo 5: (minor damage to key) A new cog stopped the back side hitting !!!

The Realities of bad maintenance: (running water pumps over 60k miles)

On many cars, a water pump failure can the timing belt by cutting through the cover and hitting it.

On Side kicks , I've seen the main water pump bearing, so bad, that the pulley flopped side to side, cutting through the front cover

and destroying the timing belt. (takes serious ignorance, to drive any car with a bad screaming water pump , huh?)

All belts fail for 1 reason, the owner did not do the 60,000 mile mandatory service. (pump not wailing away.)

FAIL ?

Many things that cause this (my) Timing belt procedure to fail, or just seems too:

There are a huge list of things that will make the new belt seem to fail , a huge list of engine failures, or EFI issues.

If you motor, now has 170PSI compression cold (sea-level) (I always do this, after this procedure), then you didn't mess up cam timing..

If below 150PSI x5 at sea-level, the cam may be off one cog. For exact compression see my compression page for correcting for altitude.

The cam likes to go retarded if the belt gets loose, and that will drop compression fast.

PIT-FALLS: (in order of popularity :

- Thinking? (stop that) that the cam is timed at #1 cylinder firing, NO, IT IS NOT, it is timed to #4 firing...

- Reversing the belts after running them or turning them inside out , (don't let kids play with the belt, or Rex the dog.)

- Not indexing the Idler base lever plate TANG (tabs) as seen in warning 31 above. see parts 5 and 7 in Drawing here.

- Not replacing belt every 60k miles (60,000) read the operators guide, this is all covered there.

- Not inspecting crank key for damage or using the new TSB

spec for the big bolt, revised in 1996 and is (94ft/lbs)

(covers all years 89-98)

- Not torquing the big 17mm crank bolt with flywheel locked.

- Using the false marks for KEY or Timing (see photo above)

- Not replacing missing or obviously damaged parts, Suzuki still sells all these parts.

- Not inspecting crank key way for damage, at least 1 time , at first day of car owner ship. (then set it up right with proper torque and Loctite'd(tm))

- Not doing the sneak-a-peak and

acid tests, when all 4 cylinders are low compression.

(at the least check it., as someone may have set the distributor to match the cams lies. That is, cam timings way off, so someone set the distributor to correct for this lie.

TILT , BUZZZZ , wrong.... check it.

LAST , do the Distributor timing.

In the same Vein, if you just suddenly see spark timing way off?, gee the cam slipped. (but leave the distributor ,please... and win)

rev6------- 9-/5-2010 (major edit). 5years later correct some spelling errors, I'm a bum. Grin !