Speedometer , Odometer, and VSS sensor testing ( Vehicle Speed Sensor):

My pages show how to work with the Speedo driver gear ratio's , cable and head , as seen below , aka: I/P cluster or Instrument Panel cluster.

The system is 100% mechanical , except the VSS switch itself, and is only a simple reed switch. "no electonics at all"

If you want to see the cable gear ratio's fast , CLICK HERE

VSS testing , I/P cluster on the bench (bench testing it) Slide show here.

- DMM meter set to

Resistance mode. "Digital Multimeter" of any kind, even a Walfart ®

meter) or any analog ohm (resistance) meter ever made.

- Connect the Ohm meter to pins V1 and V2 , (A1 and A2 on the connector.) in 94

the pins are A2 and A3 as seen below)

- Set meter to beep mode. Low ohms scale. (all meters do this) if a needle analog meter needle left is open circuit and to right is shorted.

- the Reed VSS switch is just that, a REED switch, a simple contact switch, not magic , not electronic,just a switch.

- The VSS clicks as you spin the rear of the speedo meter, (stick something in there and spin only CCW)

- As you spin that port, the VSS opens and closes many times, 0ohms, infinity, zero ohms, infinity , over and over. that is a good switch if in beep mode it beeps over and over.

- If it don't beep check the V1 and V2 screws are tigh and

clean. (some heads use, pin 1 and 2 others 2 and 3) See car EFI schematic for wire colors and now you know.

- Dismantling

is a whole other topic, but is here.

The car can have two VSS sensors

( 1 in a 3 speed or 5 speed, and 2 for a 4speed transmission) I call the 4speed sensor VSS2, at its tail shaft , this page is for the VSS1 in the cluster.

Your ECU depends very heavily on the VSS1 to run the injection system properly. ( used to calculate load, cruise data, and is a fall back device for the 4speed)

It is not optional.

The VSS acutal , almost never fails.

What fails is the Cable, feed gears .

If the CEL lamp glows and you see code 24 flash out, or the P0500 (OBD2 scan tool DTC)

DTC code 24 THROWS at : ( loss of VSS for 5 seconds during fuel cut , deceleration)

Code 24 can be set

with a binding speedo cable! Oil it with motorcyle cable oiler.

a broken cable.

a broken speedo gear at the transfer case (4wd) or at tranny tail shaft housing on 2wd.

Never attempt to spin the cable at the disconnected end of cable at the speedo cluster , with any tool / or machine, using fingers only , it will be impossible to turn (agood sign)

If you remove the cable at the bottom end , you can spin cable CCW and see speedo needle go above 0 mile per hour (km/H?)

Do not spin the cable backwards ! (only CCW facing HEAD)

Never pull on cable from top side (head) as that invites destroying the bottom cable crimp key. way bad. that is.

You can remove the internal cable (pull it out from beneath the car and lube it and put it back.) Twist it gently on re-insertion, so it dogs in to the speedo cluster port

The speedo end is a square drive.

The tail end is a key shape terminal that likes to shear or come uncripped from the end of cable, End of life on said cable..

Test 1: ( car on flat ground)

Speedo cable, you pulled loose at I/P head, , chocked front wheels.(front and rear) , get tranny into neutral or transfer case in neutral , then raise the left rear wheel.

Never in gear Park, you release the hand brake. (car is free to float so use effective chocking)

person one spins left rear wheel ,the rear prop shaft spins, the speedo cable spins in your hand, and it is impossible to stop cable with fingers.

yes?, then cable is not broken nor ar the gears in tranny tale shaft.

Actual reed switch failures are rare.

Of all the functions of this head the VSS can be a real show stopper. IT MUST WORK. Or the ECU will go quite crazy.

What is it?: It is a reed switch (magnetic) that sits inside the speedo head, that click close x amount of clicks per the turn of the rear wheels.

Its function is to tell the ECU how fast you are going and to report this to your insurance company. ( that last part, is a fib, LOL !!).

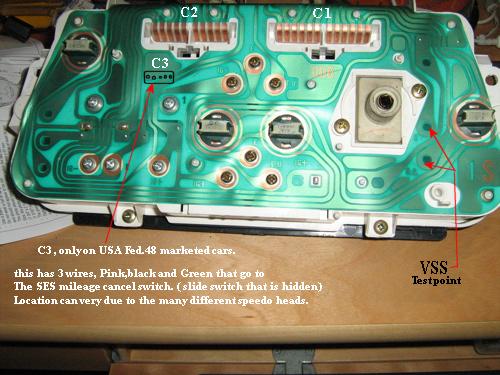

This is your speedo head, the VSS switch is located to the right. 93/94 This is a USA Fed 48 Head.

See my 91 speedo head photo.

The 91 speedo head wiring photo, is here. others are simular.

See my detailed speedo head page and see the speedo gears and choices, for all transmisions.

The reed switch rarely fails but these screw pads surely corrode, just polish them with an pencil eraser.

The speedo cable , head connector, one just tweaks the tabs lightly and pull the cable shell forward.

The main electrical 2 or 3 big connectors, just squeeze the lock tabs to release the locking connectors.

The SES Milelage NAG conn. (4pins/ 3 wires) switch connector (federal cars only) , has a backwards lock ! Spread it to unlock it ! Dont put it back it , is nothing but trouble.

Clean the 2 VSS contacts C1 AND 2 AND chean the 2 screw pads and replace the 2 washer if corroded.

Tests:

- Does the cars speedo indicate the correct speed as you are driving, if yes continue, else repair that first. (a new cable )

- Disconnect the ECU

connector blocks and connect and ohm meter blk lead to ground and

red lead to pin A15 (8v)Br-Yel or A7 (16v)yellow wire at harness. You

are not connected to observe VSS switch continuity.

- Select ohms low 200 scale or continuity with beep mode on the meter.

- Raise only the right/left (your convenience) rear tire off the ground . Transmission/transfer case, in neutral . (never in park)

- Connect DMM to VSS pins, any why you can (helper) Use DMM resistance range Rx1 or continuity mode, or battery powered test lamp.

- Rotate tire and the meter beeper (or continuity tests) will

show the switch closes a few

times each revolution, of the tire. (91' manual says few)

- The 95 manual says, the switch will click 4 times per speedo head cable rotation. the ratios are 5:1 axle and then the speedo gear ratios. combined.

- The automatic has a different ratio rear axle and matching different speedo gear.

- The speedo face (bottom) is marked with clicks per mile.

(with glass front removed)

- If the switch clicks reliably, then all is well , if not the cable is not moving (see test 1 above) or the gears are bad in speedo tranny port.

- The VSS has many important functions, including but not

limited to, AutoTranny (4sp) operation, deceleration and fuel cut, SES

function and cruise control option. Load calcultions for proper fuel

calculations , under real driving loads, moving.

- Suzuki does not sell the VSS switch seperate from the speedo head , so find a new head form a wrecker.

- Most fails are bad cable, and Corrosion at the Speedo head.

Here are the ECU connections VSS shown here.

end.

What is a reed switch? :

Good general write up on the VSS:

Here is how the whole thing works end to and.

THE, main tranny shaft spins. ( rear wheels spin, the rear prop shaft spins and the end of transfer case spins (if 2wd substitute tranny for xfr case)

the plastic worm gear #35 on same spins the speed plastic gear 35b, in the port , id 41

this gear 35b, spindle , has a hole slot and key.

the end of the speedo cable ,at xfr case (pretending 4wd)

this end has a crimped on key device on the cable end, if not crimped on any more, that cabe is bad, this device inserts into the gear. the gear spins , that cable spins.

The cable must spin at all times moving, never try to stop it from spinning while rear axle is in motiion. (breaks things)

Never pull on cable from top side (head) as that invites destroying the bottom crimp. way bad. that is.

the cable spins speedo head ( it is mounted to rear of speedo head)

the head has a gear to the odometer and trip counters.

and the same speedo head input shaft, spins a magnet

this magnet spins and the needle (not connected) is magnetically deflected upscale CCW from rear.

the faster the cable moves the more magnetic coupling energy to the needle .

the VSS clicks 4 times per cable turn.

version 1