The purpose of the EVAP system, is to capture all gasoline fumes and burn them and not allow them to be released into our atmosphere.

The first system EVAP 1, from 1989 to 1995 , was just a simple tank vent and 1 pressure valve, almost like TPC seem below.

The cap has a vacuum breaker too.

All fumes are stored in the carbon block in the canister up next to the engine.

The engine starts and the ECU opens 1 VSV valve and keeps sucking the vap CAN full time running. (Some ECUs/ need to be moving. or above idle to do the suck action)

The Smog man can not ask the ECU if the EVAP works ok, like in 1996+ EVAP2 or 3 systems.

The man, attaches a pressuer leak down tester to the gas cap next

Then pressurize to like 2 psi. and the shuts off his pump and times the leak down. if it holds for 30sconds (guess)then it passes, if it falls like a rock its got a leak

All hose to tank are suspect as is the top of tank rusty.

As is a bad TPC that leaks.

I pressurize the tank in the shop with shop air and paint regulator, for LPHV spray jobs. I set the dial to 2psi.

then cut up and old gas cap and put a vacuum fitting on the cap and attach all the above.

Last I take my spray bottle with water and 3 drops of dish soap.

I spray every thing, related and connected to this gas tank.

If see bubbles, bingo, if not, then the TPC is bad.

See below using a hose to your ear to hear hissing sounds. (way 2) to find leaks.

The above smog test can not find problems past the TPC valve. They trust all the forward parts. So is easier car do fix.

OBD2 changes the rules, in 1996:

They added a 2nd VSV valve near the gas tank.

The smog man tests this 2 ways, the above pressure test, and then asks the PCM (OBD2 scanned) if there are any DTC ERRORS FOR EVAP (DOUBLE TROUBLE)

I will first pretend the car Fails the smog test: (below 1st)

The system has evolved from a simple vent tube near the air cleaner and then later (1991) a single valve (VSV) to same point , to the below EVAP level 2 system in 1996. (some times the EVAP 2 level system happened later 1996 or 1997

The first test, is at the smog station, he/she attaches pressure leak down tester to the tank filler neck and you pass or fail.

If you fail, you must find the leak, the leak is on the rear of the car behind the Pressure Relief valve, near the tank.

To find a leak we can do a visual inspection for missing hoses, or cracked hoses near the tank, all hoses on take, not the fuel loop must be checked even the filler tube. The top of the gas tank must not be rusted through as many are. (LOOK there)

If all that checks out you then pressurize the tank using a custom gas cap (DIY or?) and a low pressure , regulator, used for spray painting and then to shop air. Set the REG to say 2 psi. Max.

Then take a rubber hose (1/4" ID against your ear, say 3 foot long, and move this hose end all over all parts connected to the gas tank, listening for the HISSSSSSS sound, the hiss sound is a leak, you just found it , now fix that.

That's it for the pressure test, but make sure the Pressure Relief valve is not stuck open (one more pressure test for that)

Ok,no more leaks above.

Phase 2 testing.

I will now presume you have EVAP DTC failures with the CEL glowing driving.....

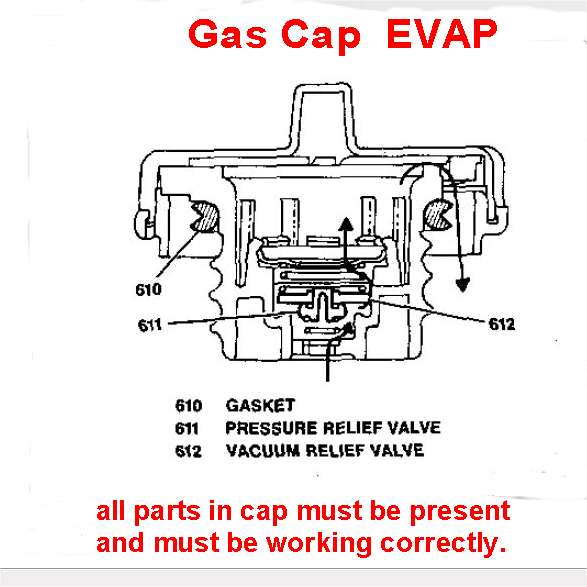

The 1st part that must work correctly is the gas cap.

This gas cap has a vacuum breaker in side IT, that allows the engine to suck fresh air in to the tank and fumes in to the engine for proper burning.

The fuel pump removes fuel from the tank and does try to cause a vacuum inside, this is normal but the CAP must have a vacuum breaker and it must be working and not stuck or clogged, Replace the cap if you suspect it, its dirt cheap and labor is costly.

The main EVAP VSV (vacuum solenoid valve) opens ,when running and especially cruising and sucks all the fumes out of the canister driving. (the ECU/PCM EVAP test monitors, are suspended on a full tank, so make sure the tank is not full)

The VSV valve must open driving and must suck air and fumes, from the Canister. The VSV coil measures about 35ohms. if infinity it's bad.

When parked at night, the system is sealed and the fumes are collected by the activated charcoal in the Canister.

If you replace the cap with a non vacuum breaking cap, the main gas tank will implode, as the collapes link, below clearly shows. (wrecking the tank and crushing the pump RACK and allowing the fuel pump to suck air, with 1/8 to 1/4 full tank, and wrecking the dry run pump)

The newer cars 1996+ can throw and store, DTC errors. (CEL GLOWING?) P0440 through P0463. (1996 and newer U.S.A, cars) Pre 1996 cars do not throw DTCs for EVAP. (the old cars just stink of raw fuel, your only warning, back then)

If the gas cap is broken clogged or the wrong cap , the tank MAYgo to a vacuum state, ( negative pressure) and the fuel pump will fail or overload and the car may bog or starve for fuel driving.. (so drive with cap missing, does it drive perfectly now? , yes, BINGO)

Not having a real EVAP rated gas cap, will make you pull your hair out. (engine bogs/stalls driving only?, ouch ! or tank collapse)

The cap allows pressure build up and never vacuum build up. When you remove the cap and it burps fumes (not sucks) that is a perfect SYSTEM a 1 PSI max pressure is there. Whoosssh is normal sound cap removal time. (on a warming day, is common event)

The OBD2 spec's will throw DTCs even for a 0.040 inch crack in the system or loose gas cap. Cap with broken 0-ring seal?

The Tank builds pressure on a warming day, as the fuel warms and the fumes warm, they expand, building pressure this is NORMAL and the pressure relief valve at about 1 PSI opens up and fumes land in the CHARCOAL canister.

The relief valve can be hand tested. PRV.

The Pressure Relief Valve (or tank presssure control or TPC) must not leak , must open at the proper tank pressure, and must not be clogged up.

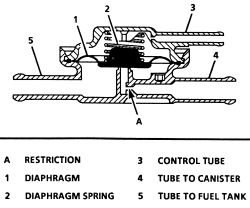

The tank pressure at #5 can push the diapharm up at about 1 PSI and the valve opens ,sending fumes to the canister. The PLM can send a vucuum to nipple 3 and open the valve too, for PCM EVAP monitor testing.

TPC

TPCApply vacuum 15 inches (about) to nipple 3, do a industry standard leak down test. It holds 15 inches, for say 30 seconds, this finds cracked diaphragms.

The with vacuum to 3 above. blow with lips (and clean hose) to 4 and 5, the path must flow one way or the other or both.

Some TPC have a valve that opens from Canistor 4 to tank 5 ports. This allows the Canister to burp back to the gas tank. (a hot canistor can do that)

-

Attach a new test hose to the TPC valve nipple marked TANK 5.

-

Blow lips, hard into the new hose at 5. Air should pass SLOWLY through the valve and out the port marked CAN 4. ("A" orifice path test)

-

Using a hand-held vacuum pump, apply vacuum to the vacuum port 3 of the TPC valve. (control tube)

-

With vacuum applied to the TPC valve @3, blow (lips) through the same new hose. Air should pass easily through the valve and out the CAN port of the TPC valve. (valve is now open test)

-

If the TPC valve did not function as indicated, replace it with a new one.

- Remove the test new hose from the TANK 5 nipple, and connect it to the CAN 4 port of the TPC valve.

-

Blow lightly through the CAN 4 hose. Air should pass freely through the valve and out the TANK nipple.

-

If the TPC valve did not function as indicated, replace it with a new one.

The Tank pressure sensor must work correctly. (same sensor up to SQ625 2003 and 1996-98 Sport)

the 1.6L has suffxi 79E20 not E10 like the 1.8L)

E10 sensor curve.

There are 3 wires to the sensor, one is ground, 0volts, and one is +5vdc (power) and one is OUTPUT the output is color Brown-red (stripe). (pink on 1.8L?)

If 5 vdc is missing the PCM is bad or the wire cut to it, or grounded out. (4.75v volts to 5.25vdc is the normal 5v supply voltage)

The output will be 0 to 4.5v, just like all 5v sensors.

Keep in mind the pressures are 0 to 1 PSI, (and vacuum)

This sensor is 2.5 volts for for 0 PSI, and goes lower for Vacuum and higher than 2.5vdc for pressure.

Our sensor is BiPolar , Plus pressure and Minus pressure (vacuum below 2.5v)

If the output is 4.5v to 5v the sensor is bad. (stuck there) FUEL cap off. keyon.

If the output is 0 volts with tank presssure at 1 PSI the sensor is bad . (TANK Cap on, keyon, tank pressure purposely set to 0.5 to 1 PSI.)

What I do is very pressure from 0 to 1 PSI and monitor that pin, if it is stuck at a voltage (or wrong voltage) it's a bad sensor. Do not be Anal about this, if it's close it is a good sensor.

DTC P0450 to 454 all are about, these sensor reading wrong.

The DTCs can't really test a good canister, for good /bad , only a clogged canistor or case rusted through. It can not test the CHARCOAL, so just make sure its there, not clogged and not rusted through. (use vacuum tool to test its air tightness and pass through ability)

1996 G16 EVAP chapter A

Chapter B level 2:

The old FSM tests are poor.

1996 G16B engine EVAP TESTING:

Evap Canister (system)

VSV = Vacuum Solenoid Valve, = an electrically operated vacuum valve.

1996 Suzuki SPORT 1.8L J18 engine car. The first year, has this setup. (its EVAP level 1)

The VSV valve count sets the Level of EVAP and the test methods. This single VSV below is it, only one, valve , no PURGE VSV.

As you can see this the red lines all can leak.

I believe the tank pressure sensor is monitored driving, and only when fuel level is below 3/4 tanks (1/4 down) the monitor starts to run and check to make sure the tank has pressure, over a long time period. say 1 hour?

and if there is no presssure you get DTC errors.

If that sensor is dead, you have false DTCs for pressure loss. and is dead wrong. (the classic is it really bad (air leaks), or is the test fibbing , issues)

The ECU/PCM may also opens the VSV valve #8 below and watch the tank pressure drop. so prove that path works too.

The VSV tests are in the FSM, here is the basic test. bench test. (there is no vent port on this VSV like the other non EVAP have.)

J18 below:

More J18.

SAE Jargon? see here.

rev 4 ++++ 9-26-2010 (and 4-14-2014) added, 1.8L sport Sidelick PDF. added EVAP1,checks.